Company Name:

Street:

Street:

Company Contact:

Phone Number:

E-Mail Address:

Beginning Date: Time:

Ending Date: Time:

AUDITOR INFORMATION

United States Department of Agriculture

Agricultural Marketing Service

Specialty Crops Program

Specialty Crops Inspection Division

Field Office:

Auditor Name(s):

Auditor Signature(s):

Commodities Covered by Audit:

Commodities Produced During

Audit:

Total Acres Covered by Audit: To

tal Square. Feet Covered by Audit

Description of Operation:

Harvest Company Name (if applicable):

Other Contractors:

Company uses USDA GAP&GHP Logo on packaging or marketing materials?

Is this company currently subject to the Produce Safety Rule (21 CFR Part 112)?

AUDIT INFORMATION

Date and Time

of Audit

Contact Title:

Fax Number:

Multiple sites covered by this audit? (If Yes, provide details in Additional Comments)

Mailing/Business Address

Federal

Same as above

Account Number:

City, State, Zip:

Audited Location Address

GPS (Optional):

City, State, Zip:

Harmonized GAP Audit Checklist

AUDITEE INFORMATION

Yes

No

Yes

No

No

Yes

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Person(s)

Interviewed:

Audit Requested by:

Distribute Audit

Report to*(if

known):

Azzule

Signature:

Date:

Audit Results Meets USDA

Acceptance Criteria

INTERNAL USE ONLY

Reviewing Official Name:

*Supplying names of retail and food service buyers is not mandatory, however it is useful to know in the event the

buyer requires USDA-AMS to send a copy of the audit report directly. No audit results are sent to a 3rd party

without the written consent of the auditee.

ADDITIONAL COMMENTS

Tomato Audit Protocol Greenhouse……………….………..……...…………….…………………

Tomato Audit Protocol Packing and Distribution ….……………...……….………………………

OTHER INFORMATION

Post-Harvest Operations……….…………………………………………………………...…………

Logo Use ………………………………………………….……………...……………………………

Tomato Audit Protocol Open-field Production and Harvesting…...............................................

Tomato Audit Protocol Packinghouse ……………………………….……………..………………

AUDIT SCOPE: (Please check all scopes audited)

General Questions (All audits must begin with and pass this portion)

Field Operations and Harvesting……………………………………………………….…….………

Yes

No

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Auditor Comments: The auditor shall document the findings associated with any question answered

"CAN" or "IAR" in the auditor comment section of the checklist. Auditors may also document

observations associated with any question on the checklist whether or not the question is a non-conformity

if the explanation clarifies why a question was answered compliant. The auditor shall write a comment for

each question answered "N/A" addressing why the question was answered "N/A".

Tallying the Audit: Once the auditor finishes the audit, the score sheet shall be filled out by recording the

number of C, CAN, IAR, and N/A's for each section of the audit. The question number of any question

answered as CAN or IAR for each section shall be noted in the last column of the score sheet.

Corrective Action Reports: The auditor shall fill out a Corrective Action Report for each question that

has been answered "CAN" or "IAR".

AUDITOR COMPLETION INSTRUCTIONS

All questions on the USDA Harmonized GAP and GAP Plus+ Standards - USDA Checklist shall be

assessed according to the Verification Instructions outlined in the Harmonized GAP and GAP Plus+ Food

Safety Standard. Auditors shall have a copy of the Standard with them when performing audits to verify

questions are assessed appropriately. All questions shall be assessed using one of the following:

Compliant (C) - The operation meets the requirements of the Harmonized GAP and

GAP Plus+ Food Safety Standard.

Corrective Action Needed (CAN) - The operation does not meet the requirement(s)

of the Harmonized GAP and GAP Plus+ Food Safety Standard, however the non-

conformance is not considered to be an immediate food safety risk.

Immediate Action Required (IAR) - The operation does not meet the requirement(s)

of the Harmonized GAP and GAP Plus+ Food Safety Standard and the non-

conformance is considered an imminent food safety risk. An imminent food safety risk

is present when produce is grown, processed, packed or held under conditions that

promote or cause the produce to become contaminated. Observation of employee

practices (personal or hygienic) that jeopardize, or may jeopardize, the safety of the

produce are considered an "IAR". The presence or evidence of rodents and an

excessive amount of insects or pests are also considered an "IAR".

Not Applicable (N/A) - The question is not applicable to the operation.

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

The acceptance criteria to meet USDA-AMS requirements are outlined on the USDA Acceptance Criteria

page, however be aware that depending on who the client(s) requiring the audit are, their specific

acceptance criteria may vary from the USDA-AMS criteria.

It is intended that the scopes of the audit selected are completed in their entirety and the audit not restricted

to one specific section. However, at the auditee's request, the audit may be split to accommodate

scheduling; however, if this is done, the audit is not complete and no certificate or web posting will be

issued until the audit is finalized.

To schedule an audit, please go to the USDA-AMS website at www.ams.usda.gov/gapghp and review the

"How to Request a GAP & GHP Audit". For auditees without internet access, please contact your local

Federal or Federal-State Specialty Crops Inspection office, or the Audit Services Branch at 202-720-5021.

Auditee Information

Auditees should download the complete USDA Harmonized GAP and GAP Plus+ Standards which

provides more complete & detailed information regarding the specific questions covered by this audit

checklist. The complete Standard is available on the USDA website at www.ams.usda.gov/gapghp.

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

1

2

3

4

5

6

If an operation does not meet the acceptance criteria as outlined above, a corrective action

report form will be issued for each nonconformance noted on the audit. The operation has the

opportunity to take measures to address the issue and schedule a new audit in order to show

compliance to the acceptance criteria.

If the auditee has been audited against the USDA GAP Plus+ Standard or the

Harmonized GAP and GAP Plus+ Food Safety Standard previously, the auditee

must have addressed all associated CANs or IARs, following their established

corrective action procedure.

Operation must have performed all risk assessments, designated with an "A" in the

DOC column, in the USDA Harmonized GAP and GAP Plus+ Standards.

In each major section (G, F, and P) of the audit, at least 80% of the questions not

answered as "N/A" must be answered as compliant.

If an operation meets the acceptance criteria as outlined above, the operation will receive a

certificate stating its conformance to the USDA Harmonized GAP and GAP Plus+ Standards as

well as being posted to the USDA website. Corrective action reports will still be supplied to

the auditee for all nonconformances.

USDA Harmonized GAP and GAP Plus+ Standards

USDA Acceptance Criteria for the

No questions are assessed as an "IAR", Immediate Action Required.

Falsification of records is considered an "IAR".

Any question marked with a ● in the MAN column must be assessed as

"compliant".

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

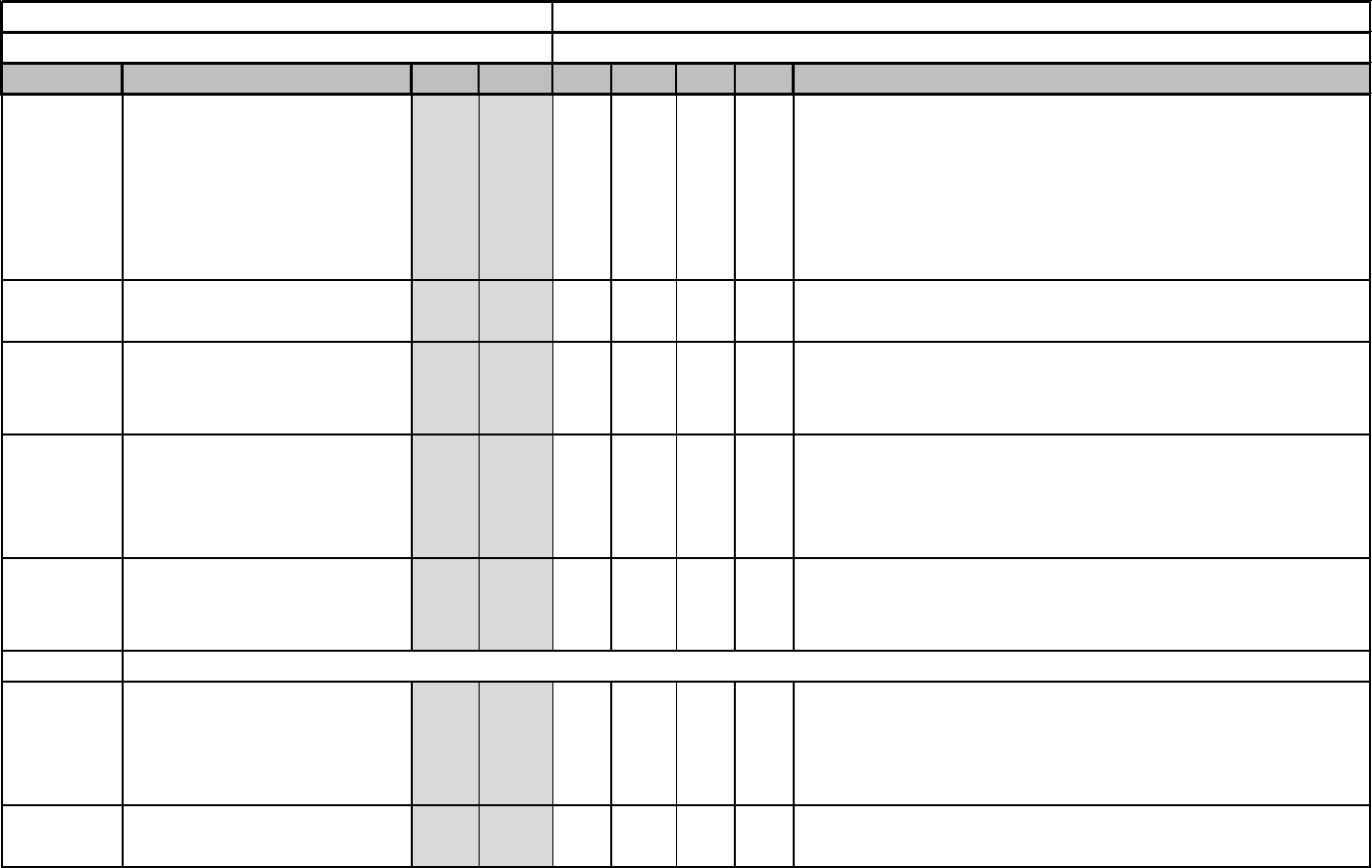

Section Questions

Total # in

Section

# of

C

# of

CAN

# of

IAR

# of

NA

Question # of any CAN or IAR

G

General Questions

72 0 0 0 14

G-1

Management Responsibility

5 0 0 0 2

G-2

Food Safety Plan or Risk Assessment

5 0 0 0 1

G-3

Documentation & Recordkeeping

4 0 0 0 1

G-4

Worker Education & Training

3 0 0 0 0

G-5

Sampling & Testing

3 0 0 0 0

G-6

Traceability

5 0 0 0 3

G-7

Recall Program

3 0 0 0 0

G-8

Corrective Actions and Food Safety

Incidents

4 0 0 0 2

G-9

Self-Audits

1 0 0 0 0

G-10

Worker Health/Hygiene and

Toilet/Handwashing Facilities

22 0 0 0 0

G-11

Agricultural and Cleaning Chemicals

9 0 0 0 1

G-12

Waste Management

2 0 0 0 0

G-13

Food Defense

4 0 0 0 2

G-14

Food Fraud

2 0 0 0 2

F

Field Operations and Harvesting

54 0 0 0 0

F-1

Field History & Assessment

5 0 0 0 0

F-2

Agricultural Chemicals/Plant Protection

Products

3 0 0 0 0

F-3

Water System Description

1 0 0 0 0

F-4

Water System Risk Assessment

6 0 0 0 0

Audit Summary

Name of Auditee:

Date of audit:

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

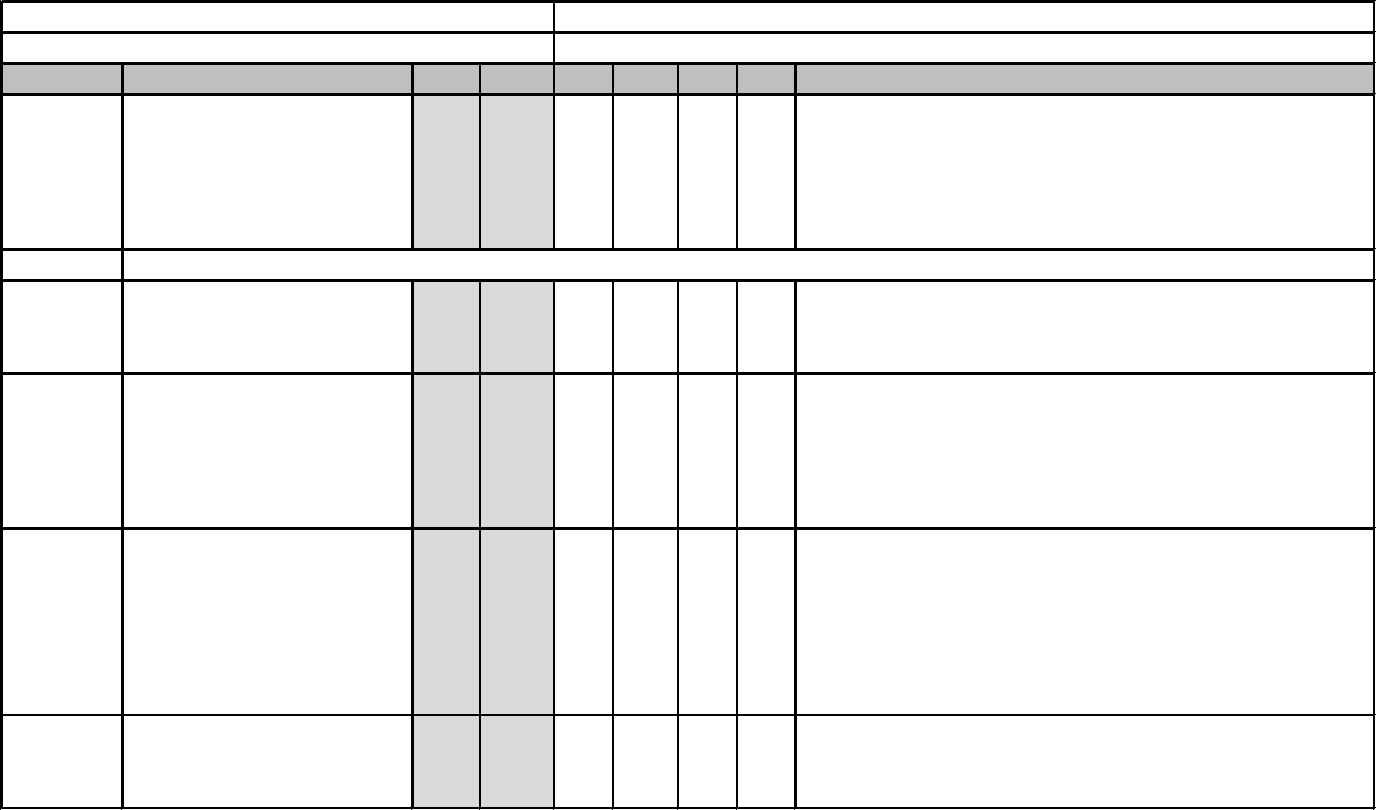

Section Questions

Total # in

Section

# of

C

# of

CAN

# of

IAR

# of

NA

Question # of any CAN or IAR

Audit Summary

Name of Auditee:

Date of audit:

F-5

Water Management Plan

3 0 0 0 0

F-6

Animal Control

3 0 0 0 0

F-7

Soil Amendments

9 0 0 0 0

F-8

Vehicles, Equipment, Tools and Utensils

1 0 0 0 0

F-9

Preharvest Assessment

6 0 0 0 0

F-10

Water/Ice Used in the Harvesting and

Postharvest Operations

4 0 0 0 0

F-11

Containers, Bins and Packaging Materials

8 0 0 0 0

F-12

Field Packaging and Handling

3 0 0 0 0

F-13

Post-harvest Handling and Storage (Field

Prior to Storage or Packinghouse)

2 0 0 0 0

P Post-Harvest Operations 65 0 0 0 0

P-1

Produce Sourcing

1 0 0 0 0

P-2

Agricultural Chemicals

7 0 0 0 0

P-3

Facility

3 0 0 0 0

P-4

Pest and Animal Control

7 0 0 0 0

P-5

Equipment, Tools and Utensils

13 0 0 0 0

P-6

Maintenance and Sanitation

9 0 0 0 0

P-7

Post-Harvest Water/Ice

9 0 0 0 0

P-8

Containers, Bins and Packaging

10 0 0 0 0

P-9

Storage

6 0 0 0 0

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Section Questions

Total # in

Section

# of

C

# of

CAN

# of

IAR

# of

NA

Question # of any CAN or IAR

Audit Summary

Name of Auditee:

Date of audit:

L Logo Use 10 0 0 0 0

L-1

Food Safety Plan or Quality Manual

2 0 0 0 0

L-2

Traceability and Recall Programs

1 0 0 0 0

L-3

Approved Suppliers

3 0 0 0 0

L-4

GAP & GHP Logo Approved Use

4 0 0 0 0

T Tomato Audit Protocol 17 0 0 0 0

TOF

Open-Field Production & Havesting

17 0 0 0 0

T Tomato Audit Protocol 24 0 0 0 0

TPH

Packinghouse

24 0 0 0 0

T

Tomato Audit Protocol

25 0 0 0 0

TGH

Greenhouse

25 0 0 0 0

T

Tomato Audit Protocol

27 0 0 0 0

TPD

Repacking and Distribution

27 0 0 0 0

C, Compliant with requirement; CAN, Corrective action needed to address nonconformance; IAR, Immediate action required because of

imminent food safety risk; N/A, not applicable or not needed.

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. #

Requirement

DOC MAN C CAN IAR NA Auditor Comments

General Questions

G-1 Management Responsibility

G-1.1

A food safety policy shall be

in place.

WP ●

G-1.1.a

The food safety policy shall

include measurable

objectives for meeting the

safety needs of products.

WP

✓

Harmonized GAP Plus+ questions are not applicable to

this audit.

G-1.2

Management has designated

individual(s) on-site and

remote, including a list of

alternatives authorized to act

in absence of designated

individuals, with roles,

responsibilities, and

resources for food safety

functions.

WP ●

G-1.2.a

The food safety plan outlines

an organizational structure

for at least those staff whose

activities affect food safety.

WP

✓

Harmonized GAP Plus+ questions are not applicable to

this audit.

G-1.3

There is a corrective action

policy for food safety

violations resulting from

employees and workers.

Name of Auditee:

Date of Audit:

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. #

Requirement

DOC MAN C CAN IAR NA Auditor Comments

Name of Auditee:

Date of Audit:

G-2 Food Safety Plan or Risk Assessment

G-2.1

There shall be a written Food

Safety Plan. The plan shall

cover the Operation. The

Operation and products

covered shall be defined.

WP ●

G-2.2

The food safety plan shall be

reviewed at least annually

and when changes that affect

the operation occur.

R

G-2.3

Operation has an approved

supplier program for all

incoming materials,

including packaging, soil

amendments, and alternative

growing media, soil-less

media, and substrates.

R ●

G-2.4

Operation has an approved

services program for all

services which may impact

the safety of the product.

R ●

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. #

Requirement

DOC MAN C CAN IAR NA Auditor Comments

Name of Auditee:

Date of Audit:

G-2.4.a

Approved supplier program

contains written procedures

for the evaluation, approval,

and continued monitoring of

suppliers and service

providers.

WP,

R

✓

Harmonized GAP Plus+ questions are not applicable to

this audit.

G-3 Documentation and Recordkeeping

G-3.1

Documentation shall be kept

that demonstrates the food

safety plan is being followed.

R ●

G-3.2

Documentation shall be

readily available for

inspection.

●

G-3.3

Documentation shall be

retained for a minimum

period of two years, or as

required by prevailing

regulation.

R ●

G-3.3.a

Food safety plan

documentation and records

shall be securely stored and

effectively controlled.

✓

Harmonized GAP Plus+ questions are not applicable to

this audit.

G-4 Worker Education and Training

G-4.1

All employees and workers

shall receive food safety

training, appropriate to their

job responsibilities.

R ●

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. #

Requirement

DOC MAN C CAN IAR NA Auditor Comments

Name of Auditee:

Date of Audit:

G-4.2

Employees and workers with

supervisory food safety

responsibilities shall receive

training sufficient to their

responsibilities.

●

G-4.3

Contracted workers are held

to the relevant food safety

standards as they would be

as employees or workers.

R ●

G-5

Sampling and Testing

G-5.1

Where laboratory analysis is

required in the food safety

plan, testing shall be

performed by a GLP

laboratory or laboratory

participating in a proficiency

testing program using

scientifically valid methods.

R

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. #

Requirement

DOC MAN C CAN IAR NA Auditor Comments

Name of Auditee:

Date of Audit:

G-5.2

Where microbiological

analysis is required in the

food safety plan, samples

shall be collected in

accordance with an

established sampling

procedure and prevailing

regulations and records kept.

WP,

R

G-5.3

All microbiological testing

as directed by the food safety

plan shall include procedures

and actions to be taken based

on the results.

WP ●

G-6

Traceability

G-6.1

A documented traceability

program shall be established.

WP,

R

●

G-6.1.a

Packaging must include

product identification.

✓

Harmonized GAP Plus+ questions are not applicable to

this audit.

G-6.1.b

If product is intended for

export, product meets

labeling regulations of the

country(ies) the product is

being exported to.

✓

Harmonized GAP Plus+ questions are not applicable to

this audit.

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. #

Requirement

DOC MAN C CAN IAR NA Auditor Comments

Name of Auditee:

Date of Audit:

G-6.1.c

If a post-harvest

operation supplies product to

a farm stand or Community

Supported Agriculture

(CSA), records tracing the

product from the

post-harvest operation to the

farm stand or CSA are

required.

R

✓

Harmonized GAP Plus+ questions are not applicable to

this audit.

G-6.2

A trace back and trace

forward exercise shall be

performed at least annually.

R

G-7

Recall Program

G-7.1

A documented recall

program, including written

procedures, shall be

established.

WP,

R

●

G-7.2

The recall program shall

have a designated recall

team.

R

G-7.3

A mock recall exercise shall

be performed at least

annually at the operation

being audited.

R

G-8 Corrective Actions and Food Safety Incidents

G-8.1

The operation shall have

documented corrective

action procedures.

WP,

R

●

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. #

Requirement

DOC MAN C CAN IAR NA Auditor Comments

Name of Auditee:

Date of Audit:

G-8.1.a

Corrective action procedures

shall include a procedure to

evaluate complaints.

WP

✓

Harmonized GAP Plus+ questions are not applicable to

this audit.

G-8.1.b

Food safety incidents are

recorded and assessed to

determine severity and risk,

and are addressed according

to a documented food safety

incident management

procedure.

R

✓

Harmonized GAP Plus+ questions are not applicable to

this audit.

G-8.2

Non-conforming product on

hold for food safety is clearly

identified and segregated

from other products and

packaging materials.

WP

R

●

G-9

Self-Audits

G-9.1

The Operation shall have

documented self-audit

procedures.

R

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. #

Requirement

DOC MAN C CAN IAR NA Auditor Comments

Name of Auditee:

Date of Audit:

G-10

Worker Health/Hygiene and Toilet/Handwashing Facilities

G-10.1

Operation shall have a policy

for toilet, handwashing,

hygiene, and health.

WP ●

G-10.2

Employees, workers, and

visitors shall be made aware

of and follow all personal

hygiene practices as

designated by the operation.

●

G-10.3

Toilet facilities and

restrooms shall be designed,

constructed, and located in a

manner that minimizes the

potential risk for product

contamination and are

directly accessible for

servicing.

●

G-10.4

Toilet facilities shall be of

adequate number, easily

accessible to employees,

workers, and visitors and in

compliance with applicable

regulations.

●

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. #

Requirement

DOC MAN C CAN IAR NA Auditor Comments

Name of Auditee:

Date of Audit:

G-10.5

The practice of disposing of

used toilet tissue on the

floor, in trash receptacles, or

in boxes is prohibited except

in situations where waste

systems are not capable of

handling toilet paper.

●

G-10.6

Toilet and wash stations

shall be maintained in a

clean and sanitary condition.

R ●

G-10.7

A response plan is in place

for spills or leaks of field

sanitation units.

WP

G-10.8

Employees and workers shall

wash their hands at any time

when their hands may be a

source of contamination.

●

G-10.9

Signage requiring

handwashing is posted.

G-10.10

Clothing, including

footwear, shall be effectively

maintained, laundered, and

worn so as to protect product

from risk of contamination.

●

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. #

Requirement

DOC MAN C CAN IAR NA Auditor Comments

Name of Auditee:

Date of Audit:

G-10.11

If gloves are used, the

operation shall have a glove

use policy.

●

G-10.12

If protective outer garments

are worn in product handling

areas, they shall be handled

in a manner to protect

against contamination.

G-10.13

The wearing of jewelry, body

piercings and other loose

objects shall be in

compliance to company

policy and applicable

regulation.

G-10.14

The use of hair coverings

shall be in compliance to

company policy and

applicable regulation.

G-10.15

Employee’s and worker’s

personal belongings shall be

stored in designated areas.

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. #

Requirement

DOC MAN C CAN IAR NA Auditor Comments

Name of Auditee:

Date of Audit:

G-10.16

Smoking, chewing, eating,

drinking (other than water),

chewing gum, spitting,

urinating, defecating, and

using tobacco, shall be

prohibited except in clearly

designated areas.

●

G-10.17

Operation shall have a policy

that break areas are located

so as not to be a source of

product contamination.

G-10.18

Drinking water shall be

available to all field

employees and workers.

R

G-10.19

Workers and visitors who

show signs of illness shall be

excluded from direct contact

with produce or food-contact

surfaces and from entering

produce handling areas.

WP ●

G-10.20

Employees and workers with

exposed cuts, sores or

lesions shall not be engaged

in handling product.

●

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. #

Requirement

DOC MAN C CAN IAR NA Auditor Comments

Name of Auditee:

Date of Audit:

G-10.21

Operation shall have and

implement a blood and

bodily fluids policy.

WP ●

G-10.22

First aid kits shall be

accessible to all employees

and workers.

G-11 Agricultural and Cleaning Chemicals

G-11.1

Use of pesticides and other

agricultural chemicals shall

comply with label directions

and prevailing regulation.

R ●

G-11.2

Pre- and postharvest

agricultural chemical use,

shall consider the maximum

residue limit (MRL)

requirements in the country

of origin or intended country

of destination.

R

G-11.3

Agricultural chemicals shall

be applied by trained,

licensed, or certified

applicators as required by

prevailing regulation.

R

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. #

Requirement

DOC MAN C CAN IAR NA Auditor Comments

Name of Auditee:

Date of Audit:

G-11.4

Water used with agricultural

chemicals shall not be a

potential source of product

or field contamination.

R

G-11.5

Use of water treatment

agricultural chemicals shall

comply with label directions

and prevailing regulation.

R ●

G-11.6

Agricultural chemical

disposal shall not be a source

of product or field

contamination.

R

G-11.6.a

Agricultural chemicals

approved for use on the

crops being grown are stored

separately from agricultural

chemicals used for other

purposes.

R

✓

Harmonized GAP Plus+ questions are not applicable to

this audit.

G-11.7

All cleaning agents shall be

appropriate for use on food

contact surfaces.

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. #

Requirement

DOC MAN C CAN IAR NA Auditor Comments

Name of Auditee:

Date of Audit:

G-11.8

Compressed air or other

gases that contact food or

food contact surfaces must

be maintained in a manner

that does not serve as a

potential source of product

contamination.

R

G-12

Waste Management

G-12.1

Operation has implemented a

waste management plan.

G-12.2

Trash shall not come in

contact with produce.

●

G-13

Food Defense

G-13.1

Operation shall assess the

potential for unauthorized

access to growing and/or

packing areas and its impact

on food safety.

A ●

G-13.2

Operation shall develop an

emergency response plan.

WP,

R

G-13.2.a

Initially and at least annually

thereafter, the operation shall

evaluate and document the

risks associated with security

(food defense), including

unintentional security risks.

A ●

✓

Harmonized GAP Plus+ questions are not applicable to

this audit.

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. #

Requirement

DOC MAN C CAN IAR NA Auditor Comments

Name of Auditee:

Date of Audit:

G-13.2.b

There shall be a written food

defense plan to mitigate risks

identified in the food defense

risk assessment.

WP,

R

✓

Harmonized GAP Plus+ questions are not applicable to

this audit.

G-14

Food Fraud

G-14.1.a

The operation shall initially

and at least annually

thereafter, evaluate and

document the risks

associated with food fraud.

A ●

✓

Harmonized GAP Plus+ questions are not applicable to

this audit.

G-14.1.b

There shall be a written food

fraud plan to mitigate risks

identified in the food fraud

risk assessment.

WP,

R

✓

Harmonized GAP Plus+ questions are not applicable to

this audit.

Code Key: A=Assessment of Risk; WP = Written Policy/Procedure/Plan; R = Record

Additional Auditor Comments:

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. #

Requirement

DOC MAN C CAN IAR NA Auditor Comments

Field Operations and Harvesting

F-1 Field History and Assessment

F-1.1

The food safety plan shall,

initially and at least annually

thereafter, evaluate and

document the risks

associated with land use

history and adjacent land use

including equipment and

structures.

A ●

F-1.1.a

Operation has performed and

documented a risk

assessment of each

production area prior to the

harvest of that location. The

risk assessment must include

potential cross contamination

between production sites.

A ●

✓

Harmonized GAP Plus+ questions are not applicable to

this audit.

F-1.1.b

Operation has identified

control measures for all

significant hazards identified

during risk assessment.

WP ●

✓

Harmonized GAP Plus+ questions are not applicable to

this audit.

Date of Audit:

Name of Auditee:

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. #

Requirement

DOC MAN C CAN IAR NA Auditor Comments

Date of Audit:

Name of Auditee:

F-1.2

For indoor growing and field

storage buildings, building

shall be constructed and

maintained in a manner that

prevents contamination of

produce.

●

F-1.3

Sewage or septic systems are

maintained so as not to be a

source of contamination.

●

F-2 Water System Description

F-2.1

A water system description

shall be available for review.

WP ●

F-2.2

The water source shall be in

compliance with prevailing

regulations.

F-2.3

Water systems shall not be

cross-connected with human

or animal waste systems.

●

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. #

Requirement

DOC MAN C CAN IAR NA Auditor Comments

Date of Audit:

Name of Auditee:

F-3 Water System Risk Assessment

F-3.1

An initial risk assessment

shall be performed and

documented that takes into

consideration the historical

testing results of the water

source, the characteristics of

the crop, the stage of the

crop, and the method of

application.

A ●

F-4 Water Management Plan

F-4.1

There shall be a water

management plan to mitigate

risks associated with the

water system on an ongoing

basis.

WP ●

F-4.2

Water testing shall be part of

the water management plan,

as directed by the water risk

assessment and current

industry standards or

prevailing regulations for the

commodities being grown.

WP ●

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. #

Requirement

DOC MAN C CAN IAR NA Auditor Comments

Date of Audit:

Name of Auditee:

F-4.3

The testing program shall be

implemented consistent with

the water management plan.

R ●

F-4.4

If water is treated to meet

microbiological criteria, the

treatment is approved and

effective for its intended use,

and is appropriately

monitored.

R ●

F-4.5

If microbial die-off is used to

achieve the operation’s

microbial criteria, operation

has documentation

supporting its use.

R ●

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. #

Requirement

DOC MAN C CAN IAR NA Auditor Comments

Date of Audit:

Name of Auditee:

F-4.6

If operation uses an

alternative approach to

regulatory microbiological

testing compared to current

industry standards or

regulations, operation has

scientific data or information

to support the alternative as

providing the same level of

public health protection.

R ●

F-5

Animal Control

F-5.1

The operation has a written

risk assessment on animal

activity in and around the

production area.

A ●

F-5.2

The operation routinely

monitors for animal activity

in and around the growing

area during the growing

season.

R

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. #

Requirement

DOC MAN C CAN IAR NA Auditor Comments

Date of Audit:

Name of Auditee:

F-5.3

Based on the risk

assessment, there shall be

measures to prevent or

minimize the potential for

contamination from animals,

including domesticated

animals used in farming

operations.

WP,

R

●

F-6 Soil Amendments and Alternative Growing Media/Substrate

F-6.1

The food safety plan shall

address risk, preparation,

use, and storage of animal-

based soil amendments or

biosolids.

A,

R

●

F-6.2

If a soil amendment

containing raw or

incompletely treated manure

is used, it shall be used in a

manner so as not to serve as

a source of contamination of

produce as required by

current industry standard or

prevailing regulation.

R ●

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. #

Requirement

DOC MAN C CAN IAR NA Auditor Comments

Date of Audit:

Name of Auditee:

F-6.3

If an alternative growing

media, soil-less media, or

substrate not of animal-

origin is used (e.g., perlite,

peat, coconut fiber, rock

wool, clay pebbles), it is

appropriate for its intended

use and stored and handled

in a manner to minimize the

risk of contamination.

WP,

R

F-7 Vehicles, Equipment, Tools and Utensils

F-7.1

Equipment, vehicles, tools

utensils and other items or

materials used in farming

operations that may contact

produce are identified.

R

F-7.2

Equipment, vehicles, tools

and utensils used in farming

operations which come into

contact with product are in

good repair, fit for purpose,

and are not a source of

contamination of produce.

WP,

R

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. #

Requirement

DOC MAN C CAN IAR NA Auditor Comments

Date of Audit:

Name of Auditee:

F-7.2.a

All equipment and

instruments which have an

effect on food safety shall be

identified, adequately

maintained and calibrated at

a frequency sufficient to

assure continuous accuracy.

R ●

✓

Harmonized GAP Plus+ questions are not applicable to

this audit.

F-7.2.b

Calibration of equipment is

traceable to a recognized

standard.

WP

✓

Harmonized GAP Plus+ questions are not applicable to

this audit.

F-7.2.c

The cleaning and sanitation

program shall include

measures for monitoring to

verify effectiveness.

WP,

R

✓

Harmonized GAP Plus+ questions are not applicable to

this audit.

F-7.3

Vehicles, equipment, tools

and utensils shall be

controlled so as not to be a

source of chemical hazards.

WP

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. #

Requirement

DOC MAN C CAN IAR NA Auditor Comments

Date of Audit:

Name of Auditee:

F-7.4

Vehicles, equipment, tools

and utensils shall be

controlled so as not to be a

source of physical hazards.

R

F-7.5

Cleaning and sanitizing

procedures do not pose a risk

of product contamination.

F-7.6

Water tanks are cleaned at a

sufficient frequency so as not

to be a source of

contamination.

WP ●

Harvesting

F-8 Preharvest Risk Assessment

F-8.1

A preharvest risk assessment

shall be performed.

A ●

F-9 Water/Ice Used in the Harvesting and Post-Harvest Operations

F-9.1

Operation has procedures for

water used in contact with

product or food contact

surfaces.

WP,

R

●

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. #

Requirement

DOC MAN C CAN IAR NA Auditor Comments

Date of Audit:

Name of Auditee:

F-9.2

Water use SOPs address the

microbial quality of water or

ice that directly contacts the

harvested crop or is used on

food-contact surfaces.

R ●

F-9.3

If an antimicrobial process or

chemical treatment is used

for harvest or post-harvest

water, it shall be used in

accordance with

manufacturer instructions

and the operation’s written

SOP.

WP,

R

●

F-9.4

If water contacting product

or food contact surfaces is re-

used, it shall be treated using

a registered or approved

antimicrobial process or

chemical treatment.

●

F-9.5

Water use SOPs address

condition and maintenance

of water-delivery system.

R ●

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. #

Requirement

DOC MAN C CAN IAR NA Auditor Comments

Date of Audit:

Name of Auditee:

F-9.6

If applicable to the specific

commodity, water use SOPs

address control of wash

water temperature.

R

F-10 Containers, Bins and Packaging Materials

F-10.1

Operation has written policy

regarding storage of

harvesting containers.

WP

F-10.2

Operation has written policy

regarding inspection of food

contact containers prior to

use.

WP

F-10.3

Operation has written policy

regarding acceptable

harvesting containers.

WP

F-10.4

Operation has written policy

prohibiting use of harvest

containers for non-harvest

purposes.

WP ●

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. #

Requirement

DOC MAN C CAN IAR NA Auditor Comments

Date of Audit:

Name of Auditee:

F-11 Field Packaging and Handling

F-11.1

Operation shall have a

written policy that visibly

contaminated, damaged or

decayed produce is not

harvested, or is culled.

WP ●

F-11.2

Product that contacts the

ground shall not be harvested

unless the product normally

grows in contact with the

ground.

WP ●

F-11.3

Harvest procedures shall

include measures to inspect

for and remove physical

hazards.

F-11.4

Cloths, towels, or other

cleaning materials that pose

a risk of cross-contamination

shall not be used to wipe

produce, unless risk

mitigation procedures are in

place.

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. #

Requirement

DOC MAN C CAN IAR NA Auditor Comments

Date of Audit:

Name of Auditee:

F-11.5

Packaging materials shall be

appropriate for their intended

use.

●

F-11.6

Packaging shall be stored in

a manner that minimizes

contamination.

F-11.7

Operation has written policy

regarding whether packaging

materials are permitted in

direct contact with the soil.

WP

F-11.8.a

The operation has

implemented a product

release procedure.

WP,

R

✓

Harmonized GAP Plus+ questions are not applicable to

this audit.

F-12 Post-Harvest Handling and Storage (Field Prior to Storage or Packinghouse)

F-12.1

Harvested produce is

handled in a manner such

that it is not likely to become

contaminated.

●

F-12.1.a

When product is field

packed, collection, storage,

and distribution points are

maintained in a clean and

hygienic condition.

✓

Harmonized GAP Plus+ questions are not applicable to

this audit.

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. #

Requirement

DOC MAN C CAN IAR NA Auditor Comments

Date of Audit:

Name of Auditee:

F-12.2

Materials that come in

contact with the produce

shall be clean and in good

repair.

WP,

R

●

F-13 Equipment Sanitation and Maintenance

F-13.1

The operation shall have a

policy, written procedures,

and a checklist to verify

cleanliness and functionality

of shipping units (e.g.,

trailer).

WP,

R

●

F-13.2

Loading/unloading

procedures and equipment

shall minimize damage to

and prevent contamination of

produce.

Code Key: A=Assessment of Risk; WP = Written Policy/Procedure/Plan; R = Record

Additional Auditor Comments:

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. #

Requirement

DOC MAN C CAN IAR NA Auditor Comments

P-1

P-1.1

The Operation has a policy

and takes affirmative steps to

ensure that all fresh produce

that are packed or stored in

the Operation are grown

following requirements in

Field Operations and

Harvesting harmonized

standard.

R

P-2

P-2.1

Operation has initially and at

least annually thereafter,

performed a documented risk

assessment of the

packinghouse, and has

addressed all identified risks.

A ●

P-2.1.a

If microbiological hazards

requiring a control are

identified in the risk

assessment of the

packinghouse a microbial

environmental monitoring

program shall be established.

WP,

R

✓

Harmonized GAP Plus+ questions are not applicable to

this audit.

Name of Auditee:

Date of Audit:

Post-Harvest Operations

Produce Sourcing

Facility

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. #

Requirement

DOC MAN C CAN IAR NA Auditor Comments

Name of Auditee:

Date of Audit:

P-2.2

Building shall be located,

designed, constructed, and

maintained in a manner that

prevents contamination of

produce during handling,

storage, and cooling.

P-2.3

Adequate lighting shall be

provided in all areas.

P-2.4

Only essential glass and

brittle plastic shall be present

in the building.

R

P-2.5

Catwalks above product

zones are protected to

prevent produce or

packaging contamination.

P-2.6

If applicable, operation has a

written Allergen Control

Program.

A,

WP

●

P-3

Pest and Animal Control

P-3.1

Operation has procedures to

manage pests to the extent

appropriate to the operation.

WP,

R

●

P-3.2

Operation restricts animals

from food handling areas.

●

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. #

Requirement

DOC MAN C CAN IAR NA Auditor Comments

Name of Auditee:

Date of Audit:

P-3.3

If used, pest control devices,

including rodent traps and

electrical flying insect

devices, are located to not

contaminate produce or food

handling surfaces.

P-4 Equipment, Tools and Utensils

P-4.1

All food contact equipment,

tools and utensils are

designed and made of

materials that are easily

cleaned and maintained.

WP ●

P-4.2

Equipment is installed in a

way that provides access for

cleaning.

P-4.3

Equipment lubrication is

managed so as not to

contaminate food products.

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. #

Requirement

DOC MAN C CAN IAR NA Auditor Comments

Name of Auditee:

Date of Audit:

P-4.4

All instruments or tools (e.g.,

test strips, titration kits) used

to measure temperature, pH,

antimicrobial levels and/or

other important devices used

to monitor requirements in

this section shall be

adequately maintained and

calibrated at a frequency

sufficient to assure

continuous accuracy.

R ●

P-4.4.a

Calibration of equipment is

traceable to a recognized

standard.

WP

✓

Harmonized GAP Plus+ questions are not applicable to

this audit.

P-4.5

Foreign material control

devices are inspected and

maintained.

R

P-4.5.a

Metal detection equipment,

if utilized, shall be checked

at a scheduled frequency as

outlined in the operation’s

food safety/HACCP plan

using iron, non-iron and

stainless-steel testing wands.

R

✓

Harmonized GAP Plus+ questions are not applicable to

this audit.

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. #

Requirement

DOC MAN C CAN IAR NA Auditor Comments

Name of Auditee:

Date of Audit:

P-5

P-5.1

A preventive maintenance

schedule with related SOPs

shall be established.

WP,

R

●

P-5.1.a

Routine housekeeping

practices must be

implemented.

✓

Harmonized GAP Plus+ questions are not applicable to

this audit.

P-5.2

A master cleaning schedule

with related SOPs shall be

established.

WP,

R

●

P-5.3

Any temporary repairs on

food contact surfaces are

constructed of food-grade

material. Operation has a

procedure to ensure that

permanent repairs are

implemented in a timely

manner.

P-5.4

Cleaning equipment and

tools are clean, in working

order and stored properly

away from product handling

areas.

P-5.5

Food contact surfaces shall

be cleaned, sanitized, and

maintained according to the

food safety plan.

R ●

Maintenance and Sanitation

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. #

Requirement

DOC MAN C CAN IAR NA Auditor Comments

Name of Auditee:

Date of Audit:

P-5.5.a

The cleaning and sanitation

program shall include

measures for monitoring to

verify effectiveness.

WP,

R

✓

Harmonized GAP Plus+ questions are not applicable to

this audit.

P-5.6

Transporting equipment shall

be maintained to prevent

contamination of products

being transported.

R

P-5.7

Waste materials and their

removal are managed to

avoid contamination.

●

P-5.8

Outside garbage receptacles/

dumpsters are closed and

located away from building

entrances and the area

around such sites is

reasonably clean.

P-5.9

The plant grounds are

reasonably free of litter,

waste culls, vegetation,

debris and standing water.

P-5.10

Sewage or septic systems are

maintained so as not to be a

source of contamination.

●

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. #

Requirement

DOC MAN C CAN IAR NA Auditor Comments

Name of Auditee:

Date of Audit:

P-5.11

The sewage disposal system

is adequate for the process

and maintained to prevent

direct or indirect product

contamination.

●

P-6

Post-Harvest Water/Ice

P-6.1

A postharvest water system

description shall be prepared.

R ●

P-6.2

Documented scheduled

assessment of water system

including delivery equipment

shall be performed.

R ●

P-6.3

Water use SOPs address the

microbial quality of water or

ice that directly contacts the

harvested crop or is used on

food-contact surfaces.

R ●

P-6.4

The operation’s food safety

plan includes the produce

washing process, if used.

A,

WP

●

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. #

Requirement

DOC MAN C CAN IAR NA Auditor Comments

Name of Auditee:

Date of Audit:

P-6.5

Re-used water that contacts

product or food contact

surfaces shall be treated

using a registered or

approved antimicrobial

process or chemical

treatment.

●

P-6.6

If a postharvest water

antimicrobial treatment is

used, it shall be used in

accordance with established

operational procedure and

manufacturer instructions.

R ●

P-6.7

If applicable to the specific

commodity, water use SOPs

address control of immersion

water temperature.

R

P-6.8

Water change schedules shall

be developed for all uses of

water where water is re-used.

P-6.9

Debris, damaged and/or

visibly contaminated produce

shall be removed from wash

areas/dump tanks to the

extent possible.

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. #

Requirement

DOC MAN C CAN IAR NA Auditor Comments

Name of Auditee:

Date of Audit:

P-7 Containers, Bins and Packaging

P-7.1

Specifications for all

packaging materials and

labels that impact finished

product safety shall be

provided and comply with

prevailing regulations.

R

P-7.2

Operation has a written

procedure for inspecting

incoming packaging

materials

WP,

R

P-7.3

Operation has written policy

regarding storage and post-

storage handling of product-

contact containers.

WP

P-7.4

Materials that come in

contact with the produce

shall be clean and in good

repair.

WP,

R

P-7.5

Operation has written policy

regarding whether product-

contact containers are

permitted in direct contact

with the ground or floor.

WP

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. #

Requirement

DOC MAN C CAN IAR NA Auditor Comments

Name of Auditee:

Date of Audit:

P-7.6

Operation has written policy

regarding inspection of food

contact containers and bins

prior to use.

WP

P-7.7

Operation has written policy

regarding acceptable product-

contact containers.

WP ●

P-7.8

Operation has written policy

prohibiting use of product-

contact containers for non-

product purposes unless

clearly marked or labeled for

that purpose.

WP

P-7.9

Pallets shall be kept clean

and in good condition as

appropriate for their intended

use.

P-8

Storage

P-8.1

Product storage areas and

conditions shall be

appropriate to the

commodities stored.

P-8.2

Iced produce is handled so as

not to serve as a source of

contamination.

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. #

Requirement

DOC MAN C CAN IAR NA Auditor Comments

Name of Auditee:

Date of Audit:

P-8.3

Non-product storage areas

shall be maintained so as not

to be a source of product or

materials contamination.

P-8.4

Food packaging and packing

materials shall be stored in a

manner that minimizes

contamination.

P-8.4.a

The operation has a

procedure to ensure that

purchased materials, work in

progress and finished

products are used in the

correct order, and within the

allocated shelf life when

applicable.

WP

✓

Harmonized GAP Plus+ questions are not applicable to

this audit.

P-8.5

Adequate space shall be

maintained between rows of

stored materials to allow

cleaning and inspection.

WP

P-8.6

All chemicals shall be stored

in a secure separate area. All

chemicals shall be properly

labeled.

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. #

Requirement

DOC MAN C CAN IAR NA Auditor Comments

Name of Auditee:

Date of Audit:

P-8.7

When produce is cooled, it is

cooled to temperatures

appropriate to the

commodity according to

current established

regulatory or industry

standards.

R

P-8.8

Where temperature control is

required by the food safety

plan, cooling facilities shall

be fitted with temperature

monitoring equipment or

suitable temperature

monitoring device.

R

P-8.9

Cooling equipment shall be

maintained so as not to be a

source of product

contamination.

WP,

R

●

P-9 Transportation (Packinghouse to Customer)

P-9.1

There is a written policy for

transporters and conveyances

to maintain a specified

temperature(s) during transit.

WP

P-9.2

Prior to loading, the vehicle

shall be pre-cooled.

WP,

R

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. #

Requirement

DOC MAN C CAN IAR NA Auditor Comments

Name of Auditee:

Date of Audit:

P-9.3

The refrigerated transport

vehicles shall have properly

maintained and fully

functional refrigeration

equipment.

WP

P-9.4

Where required,

temperatures of product are

taken and recorded prior to

or upon loading.

WP,

R

P-9.5

The operation shall have a

policy, written procedures,

and a checklist to verify

cleanliness and functionality

of shipping units (e.g.,

trailer).

WP,

R

●

P-9.6

Loading/unloading

procedures and equipment

shall minimize damage to

and prevent contamination of

produce.

Code Key: A=Assessment of Risk; WP = Written Policy/Procedure/Plan; R = Record

Additional Auditor Comments:

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

1

2

3

Req. # Requirement DOC MAN

C CAN IAR NA

Auditor Comments

Additional questions required for operations approved to use the USDA GAP & GHP Logo

L-1 Food Safety Plan or Quality Manual

L-1.1

The operation’s food safety

plan or quality manual

contains procedures on how

the USDA GAP & GHP logo

will be used.

WP ●

L-1.2

There is a designated person

to be responsible for the

control of inventory bearing

the logo.

WP ●

L-2 Traceability and Recall Program

L-2.1

The operation uses the

USDA GAP & GHP logo

only on packages, containers,

or consumer units which are

traceable.

WP ●

The USDA Logo Use Addendum acceptance criteria is as follows:

No questions are assessed as an "IAR", Immediate Action Required.

Falsification of records is considered an "IAR".

All questions not answered as "NA" are answered as compliant.

Note: An official identification logo has been developed in conjunction with the USDA GAP & GHP program which may be used to

indicate participation in the program. Participants may use the logo, provided they meet the requirements of the USDA logo use instructions

found at www.ams.usda.gov/gapghp and meet the requirements of this audit. Failure to meet the audit will result in steps taken in

accordance with the USDA logo use instructions.

Name of Auditee:

Date of Audit:

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Name of Auditee:

Date of Audit:

L-3

Approved Suppliers

L-3.1

The Operation has supplied a

list of approved suppliers to

the local Federal or State

auditor’s office.

R ●

L-3.2

All suppliers currently in use

by the operation are listed on

the supplied list of approved

suppliers.

WP, R ●

L-3.3

All suppliers have

successfully completed and

met the requirements of a

USDA approved GAP &

GHP audit (USDA

GAP&GHP audit,

commodity specific audit, or

Produce GAPs Harmonized

Audit, or Harmonized GAP

Plus+ Audit) .

R ●

L-4 GAP & GHP Logo Approved Use

L-4.1

The logo is only used on

products, processes, and

packaging as approved on the

SC-652.

R ●

L-4.2

All packaging or labels,

which bear the GAP & GHP

logo, are accountable items.

WP, R ●

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Name of Auditee:

Date of Audit:

L-4.3

The operation’s inventory list

of these packaging or labels

is maintained and current.

R ●

L-4.4

The logo is only used on

packaging and labels that are

clean and bright in

appearance, without marks,

stains, or other evidence of

previous use.

R ●

Code Key: WP = Written Policy/Procedure; R = Record

Additional Auditor Comments:

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. # Requirement DOC MAN

C CAN IAR NA

Auditor Comments

TOF - 1

TOF-1.1

Operation has current copies

of the Commodity Specific

Food Safety Guidelines for

the Fresh Tomato Supply

Chain, Food Safety Programs

and Auditing Protocol for the

Fresh Tomato Supply Chain,

the relevant Harmonized

Food Safety Standard, and

additional food safety

documents as required by

state and/or federal

regulation.

R ●

TOF - 2

Self-Audits

TOF-2.1

Operation has procedures for

conducting self-audits and

conducts self-audits to verify

compliance with established

internal policies and

procedures.

WP,

R

●

Management Responsibility

Name of Auditee:

Date of Audit:

Additional questions required for operations requesting to use the USDA Tomato Audit Protocol Open-field Production

and Harvesting

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. # Requirement DOC MAN

C CAN IAR NA

Auditor Comments

Name of Auditee:

Date of Audit:

TOF - 3 Field History and Pre-harvest Assessments

TOF-3.1

If the field is subject to

flooding, operation has an

established decision tree or

corrective action plan in the

event of flooding in the

production area. Procedures

prohibit harvest of product

that has come into contact

with flood waters.

WP ●

TOF-3.2

Operation shall conduct the

required Combined

Harmonized Standard F-9.1

pre-harvest risk assessment

no more than five (5) days

from the first scheduled

harvest date.

A ●

TOF - 4 Workers Health/Hygiene and Toilet/Handwashing Facilities

TOF-4.1

A response plan is in place in

the event of a major spill or

leak of field sanitation units.

WP, R ●

TOF-4.2

If hand wash water tanks are

used, they are cleaned and

sanitized and the water is

changed periodically.

R ●

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. # Requirement DOC MAN

C CAN IAR NA

Auditor Comments

Name of Auditee:

Date of Audit:

TOF-4.3

Policies shall require hand

washing with soap and

potable water at the

appropriate time, such as

before starting work, after

use of toilet facilities, after

breaks and when hands may

have become contaminated.

Policy shall apply to

employees, outside

contractors, inspectors, and

visitors. Compliance is

emphasized by management.

WP,

R

●

TOF-4.4

If gloves are used, there must

be a written SOP regarding

their use.

WP, R ●

TOF - 5

Pesticides

TOF-5.1

Pesticide Usage Water used

to mix pesticides meets FDA

E. coli standards for water in

21 CFR § 112.44(a); i.e., no

detectable generic E. coli in

100 mL of agricultural water.

R ●

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. # Requirement DOC MAN

C CAN IAR NA

Auditor Comments

Name of Auditee:

Date of Audit:

TOF - 6 Water Used in Growing Activities

TOF-6.1

Non-Foliar The water test

meets FDA E. coli standards

for foliar application water as

described in 21 CFR §

112.44(b).

R ●

TOF-6.2

Foliar The water test meets

FDA standards for water in

21 CFR § 112.44(a); i.e., no

detectable generic E. coli in

100 milliliters (mL) of

agricultural water.

R ●

TOF - 7

Soil Amendments

TOF-7.1

If fertilizers containing

manures or composts are

used, only properly treated

(composted or heat treated)

manures are allowed for use

in fields. Biosolids are not

permitted.

R ●

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. # Requirement DOC MAN

C CAN IAR NA

Auditor Comments

Name of Auditee:

Date of Audit:

TOF - 8 Sanitizing Agents Used During Harvest

TOF-8.1

All compounds used to clean

or sanitize food contact

containers, tools, utensils,

equipment or other food

contact surfaces are approved

for that use by the US EPA,

FDA or other prevailing

agency. Actual use conforms

to label directions.

R ●

TOF - 9

Product Containers

TOF-9.1

Reusable product bins, trays

and containers are made of

impervious materials that can

be cleaned and sanitized.

WP ●

TOF-9.2

Operation has a policy that

requires bins, trays, and

boxes made of corrugated

cardboard are for single use

only.

WP ●

TOF-9.3

SOP specifies that workers

do not remove harvest

buckets from the field.

WP ●

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. # Requirement DOC MAN

C CAN IAR NA

Auditor Comments

Name of Auditee:

Date of Audit:

TOF-10

Field Packing of Tomatoes

TOF-

10.1

Packing containers shall be

labeled as to their source, and

to identify that the product

has been field packed.

R ●

Code Key: WP = Written Policy/Procedure; R = Record

Additional Auditor Comments:

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. # Requirement DOC MAN

C CAN IAR NA

Auditor Comments

Additional questions required for operations requesting to use the USDA Tomato Audit Protocol Packinghouse

TPH - 1 Management Responsibility

TPH-1.1

Operation has current copies

of the Commodity Specific

Food Safety Guidelines for

the Fresh Tomato Supply

Chain, Food Safety Programs

and Auditing Protocol for the

Fresh Tomato Supply Chain,

the relevant Harmonized

Food Safety Standard, and

additional food safety

documents as required by

state and/or federal

regulation.

R ●

TPH-1.2

Operation has been

registered or permitted as a

food handling establishment

as required by state or federal

regulation.

R ●

Name of Auditee:

Date of Audit:

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. # Requirement DOC MAN

C CAN IAR NA

Auditor Comments

Name of Auditee:

Date of Audit:

TPH - 2

Raw Material Sourcing

TPH-2.1

The operation has a policy

and takes affirmative steps to

ensure that all fresh tomatoes

that are packed or stored in

the facility are grown

following requirements in

Tomato Metrics Audit -

Open Field Production,

Harvest and Field Packing.

WP ●

TPH-2.2

Operation has procedures to

ensure that the tomato

staging area and staging

practices do not pose a risk

of tomato contamination.

WP ●

TPH - 3 Traceability

TPH-3.1

Lot identification shall be

labeled on all cases and

clearly legible.

WP ●

TPH - 4

Self-Audit

TPH-4.1

Operation has procedures for

conducting self-audits and

conducts self-audits to verify

compliance with established

internal policies and

procedures

WP, R ●

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. # Requirement DOC MAN

C CAN IAR NA

Auditor Comments

Name of Auditee:

Date of Audit:

TPH - 5 Product Containers and Packaging Materials

TPH-5.1

Tomato-contact bulk bins,

gondolas, totes and trays

shall not be constructed of

wood.

WP ●

TPH-5.2

The operation has written

procedures for cleaning and

sanitizing of produce food

contact containers, requiring

that bulk bins, gondolas,

totes and trays are cleaned

and sanitized periodically

and is documented.

WP,

R

●

TPH-5.3

Operation has a policy that

requires bins, trays, and

boxes made of corrugated

cardboard are for single use

only.

R ●

TPH - 6 Packinghouse Condition and Equipment

A.

General Building

TPH-6.1

Facility is constructed/

arranged to allow separation

of incoming, in-process and

finished products.

R ●

For Official Government Use Only

USDA, AMS, SCP, Specialty Crops Inspection Division

USDA Harmonized GAP Standard V. 3.0 and Plus+ Standard V. 5.0

May 24, 2024

USDA Checklist

Version 6.1

Req. # Requirement DOC MAN

C CAN IAR NA

Auditor Comments

Name of Auditee:

Date of Audit:

TPH-6.2

Operation has procedures

that minimize the

accumulation of standing

water.

WP ●

B.

Facility and Equipment

TPH-6.3

All food contact surfaces are

made of material and

designed to be easily cleaned

and sanitized, and are

maintained in good

condition.

●

TPH-6.4

Wood is not used as a food

contact surface.

●

TPH-6.5

SDS are on file for all

chemicals used in the

facility, and readily