U.S. Department

of Transportation

Federal Transit

Administration

FTA-MA-90-5006-02-01

DOT-VNTSC-FTA-02-01

Handbook for Transit

Safety and Security Certification

Prepared by:

U.S. Department of Transportation

Research and Special Programs Administration

John A. Volpe National Transportation Systems Center

Cambridge, MA 02142-1093

Final Report

November 2002

Prepared for:

Federal Transit Administration

Office of Safety and Security

Washington, DC 20590

FT

A

O

FF

I

C

E

O

F

S

A

F

E

T

Y

A

ND

S

E

C

UR

I

T

Y

FTA

Federal Transit

Administration

★

★

★

★

★

★

★

★

★

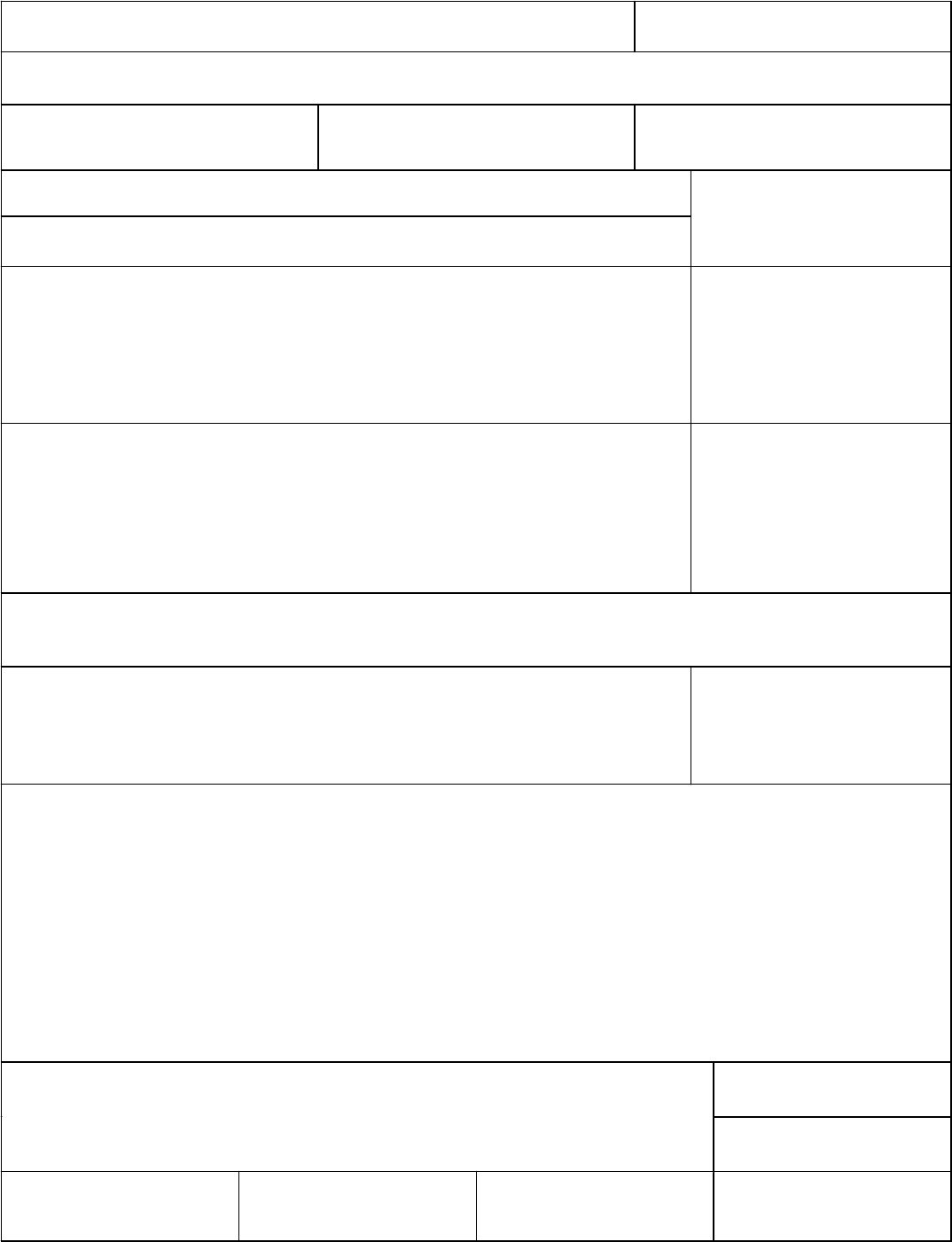

REPORT DOCUMENTATION PAGE

Form Approved

OMB No. 0704-0188

Public reporting burden for this collection of information is estimated to average 1 hour per response, including the time for reviewing instructions, searching existing data sources, gathering and maintaining the

data needed, and completing and reviewing the collection of information. Send comments regarding this burden estimate or any other aspect of this collection of information, including suggestions for reducing

this burden, to Washington Headquarters Services, Directorate for Information Operations and Reports, 1215 Jefferson Davis Highway, Suite 1204, Arlington, VA 22202-4302, and to the Office of Management

and Budget, Paperwork Reduction Project (0704-0188), Washington, DC 20503.

1. AGENCY USE ONLY (Leave blank)

2. REPORT DATE

November 2002

3. REPORT TYPE AND DATES COVERED

Final Report

September 2000 – November 2002

4. TITLE AND SUBTITLE

Handbook for Transit Safety and Security Certification

5. FUNDING NUMBERS

U2169/TM20A

6. AUTHOR(S)

Robert J. Adduci, Annabelle Boyd, and Jim Caton

7. PERFORMING ORGANIZATION NAME(S) AND ADDRESS(ES)

U.S. Department of Transportation

Research and Special Programs Administration

Volpe National Transportation Systems Center

55 Broadway, Kendall Square

Cambridge, MA 02142-1093

8. PERFORMING ORGANIZATION

REPORT NUMBER

DOT-VNTSC-FTA-02-01

9. SPONSORING/MONITORING AGENCY NAME(S) AND ADDRESS(ES)

U.S. Department of Transportation

Federal Transit Administration

Office of Program Management,

Office of Safety and Security

Washington, DC 20590

10. SPONSORING/MONITORING

AGENCY REPORT NUMBER

DOT-FTA-MA-90-5006-02-01

11. SUPPLEMENTARY NOTES

12a. DISTRIBUTION/AVAILABILITY STATEMENT

This document is available to the public through the National Technical Information Service,

Springfield, VA 22161

12b. DISTRIBUTION CODE

13. ABSTRACT (Maximum 200 words)

The Joint Task Force on Safety and Security Certification, established between the Federal Transit Administration (FTA) and the

American Public Transportation Association (APTA), prepared this Handbook to support the efforts of the transit industry to

achieve continuous improvement in safety and security performance. This Handbook provides a guide for establishing a

certification program to address safety and security that identifies the key activities; incorporates safety and security more fully

into transit projects; highlights resources necessary to develop and implement a certification program for safety and security; and

provides tools and sample forms to promote implementation of the safety and security certification process.

14. SUBJECT TERMS

System safety; system security; safety certification; verification

15. NUMBER OF PAGES

54

16. PRICE CODE

17. SECURITY CLASSIFICATION

OF REPORT

Unclassified

18. SECURITY CLASSIFICATION

OF THIS PAGE

Unclassified

19. SECURITY CLASSIFICATION

OF ABSTRACT

Unclassified

20. LIMITATION OF ABSTRACT

NSN 7540-01-280-5500 Standard Form 298 (Rev. 2-89)

Prescribed by ANSI Std. 239-18

Page ii

Foreword

The Joint Task Force on Safety

and Security Certification,

established between the Federal

Transit Administration (FTA)

and the American Public

Transportation Association

(APTA), prepared this

Handbook to support the effo

rts

of the transit industry to ach

ieve

continuous improvement in safety and security performance.

Federal Transit Administration

Online Resources

Office of Safety and Security http://www.fta.dot.gov (click on “Safety

and Security)

National Transit Library: http://www.fta.dot.gov/ntl/index/html

Planning http://www.fta.dot.gov/ntl/planning/index.html

Best Practices http://www.fta.dot.gov/ntl/bestpractices/index.html

Procurement http://www.fta.dot.gov/ntl/procurement/index.html

Policy http://www.fta.dot.gov/ntl/policy/index.html

The practice described in this Handbook is the result of a year-long research and

consensus-building mission, that included the review of dozens of industry programs and

plans; the collection of issue-specific information from transit safety and security

directors, project managers, contractors, operations personnel, and FTA Regional

Offices; presentations and working sessions with industry representatives; and requests to

industry for review and comment on draft materials.

This Handbook provides a guide for establishing a certification program to address safety

and security that:

American Public Transportation Association

• Identifies the key

Online Resources

activities

APTA recently added the “Transit Safety Corner” – an ongoing source of

• Incorporates safety and

information on safety issues critical to the public transportation industry—to its

security more fully into

web site. You can access APTA’s Safety Corner at:

transit projects

http://www.apta.com/services/safety/index.htm

• Highlights resources

The site also offers a Question and Answer section that is available to the

industry. The site is designed to address questions that are of concern to a

necessary to develop

particular agency. The responses are generated automatically to any individual

and implement a

who has requested their name be placed on APTA’s ‘list server.’ The list

certification program

server is made up on individuals from various agencies that have agreed to

become part of this process. If you would like to be placed on the ‘list server’

for safety and security

write to the Safety and Securi ty section at www.apta.com .

• Provides tools and sample forms to promote implementation of the safety and

security certification process

This Handbook is not intended to be prescriptive in nature. Rather, information can be

tailored to suit the individual needs of transit projects. The transit agencies are

responsible for determining applicability of these concepts to their own projects or

developing other workable processes. Differences in methodology may exist among

transit agencies, as well as among projects within a single transit agency.

Page iv

Joint FTA-APTA Task Force on Safety and Security Certification

Harry Saporta, Chairman

Federal Transit Administration, Office of Safety and Security

Bill Grizard, Vice-Chairman

American Public Transportation Association

Bob Adduci, Volpe National Transportation Systems Center

Don Dzinski, Egis, Inc.

Howard Fegles, Oregon Department of Transportation

Roy Field, Federal Transit Administration, Office of Safety and Security

Fred Goodine, Washington Metropolitan Area Transit Authority

Greg Hull, American Public Transportation Association

Linda Meadow, Linda J. Meadow & Associates

Conrad Santana, Siemens, Tren Urbano

Bob Sedlock, New Jersey Department of Transportation

Maria Taylor, American Public Transportation Association

Supporting Members -- The following individuals contributed generously of their time and materials in preparation of this

Handbook

:

SAFETY: SECURITY:

Harvey Becker, San Francisco Municipal Railway Dan Cowden, Los Angeles County

Luke Chisenhall, Dallas Area Rapid Transit Metropolitan Transportation Authority

Jack Collins, Santa Clara Valley Transportation Authority Paul Lennon. Los Angeles County

Michael Conlon, Metropolitan Council, Hiawatha Light Rail Metropolitan Transportation Authority

Tom Eng, Los Angeles Metropolitan Transportation Authority Clark Lynch, Bay Area Rapid Transit

Jack Graham, Dallas Area Rapid Transit Joe McKinney, Metropolitan Atlanta

Len Hardy, Bay Area Rapid Transit Regional Transportation Authority

Hugh Johnson, Utah Transit Authority David Scott, Southeastern Pennsylvania

Pamela McCombe, Greater Cleveland Regional Transit Transportation Authority

Authority

Henry Miranda, Bay Area Rapid Transit

Brian Moriarty, TRW

Laura Smith, New York Metropolitan Transportation

Authority

Nagal Shashidhara, Hudson-Bergen Light Rail

Nancy Shea, Massachusetts Bay Transportation Authority

Roger Wood, GMAEC-DMJM, Tren Urbano

STATE SAFETY OVERSIGHT:

Brian Cristy, Massachusetts Department of Telecommunications and Energy

Ray Jantzen, Colorado Public Utilities Commission

Robert Strauss, California Public Utilities Commission

Bob Kraus, Missouri Department of Economic Development

Technical Support -- Annabelle Boyd and James Caton, of the BCG Transportation Group, Inc.

supported the development and documentation of Task Force research, findings and recommendations in

this Handbook.

Page v

Table of Contents

Title Page

Acknowledgments vii

Organization viii

Chapter 1: The Basics 1

Certification as Part of System Safety and Security 1

Safety and Security Certification Benefits 3

Transit Agency Commitment 4

Responsibility for SSC Program 5

Committee Involvement 5

Application of the Project Life Cycle 6

Sample Activities 7

Project Team Support for the SSC 9

Managing Documentation 10

Safety Audit Program 10

Chapter 2: The Tools 11

Scope of the SSC Program 11

Safety and Security Certification Plan 12

Steps in the SSC Methodology 14

Step 1: Identify Certifiable Elements 15

Step 2: Develop Safety and Security Design Criteria 18

Step 3: Develop and Complete Design Criteria Conformance Checklist 20

Step 4: Perform Construction Specification Conformance 22

Step 5: Identify Additional Safety and Security Test Requirements 26

Step 6: Perform Testing and Validation in Support of the SSC Program 27

Step 7: Manage Integrated Tests for the SSC Program 28

Step 8: Manage “Open Items” in the SSC Program 30

Step 9: Verify Operational Readiness 31

Step 10: Conduct Final Determination of Project Readiness and Issue Safety 32

and Security Certification

APPENDIX A: Life Cycle Definitions 35

APPENDIX B: Useful References 37

APPENDIX C: Resource Guide 39

APPENDIX D: Sample Design and Construction Specification 41

Conformance Form and Directions

Page vi

List of Figures

Title Page

Figure 1: Safety and Security Core Management Functions 2

Figure 2: Typical Transit Project Life Cycle 6

Figure 3: Project Development Safety and Security Activities 8

Figure 4: Contributions of Project Team to SSC 9

Figure 5: Engineering Breakdown Structure 15

Figure 6: Sample Certifiable Elements and Sub-elements List 16

: Certifiable Elements and the Certification Process 17 Figure 7

Figure 8: Safety and Security Specification Development Inputs 18

Figure 9: Safety and Security Design Criteria and Project Specification 19

Figure 10: Design Criteria Conformance Checklist 21

Figure 11 Sample Specification Conformance Checklist 23

Figure 12: Sample Specification Conformance Checklist with Non-compliance 24

Figure 13: Sample Design and Construction Conformance Checklist with 25

Directions

Figure 14: Required Test Description Sheet 26

Figure 15: Test Program Planning Process 27

Figure 16: Sample Integrated Testing Sheet 29

Figure 17: Sample Close-out Report 30

Figure 18: Project Safety and Security Certificate 33

Page vii

Acknowledgments

The Task Force is extremely grateful for the contributions made to this Handbook from

its safety and security partners in industry and State government:

Four new start systems, Utah Transit Authority (UTA) Transit Express Rail

System (TRAX), New Jersey Transit’s (NJT) Hudson-Bergen Light Rail Transit

(HBLRT) System, Metropolitan Council’s Hiawatha Light Rail Line (Metro

Transit), and the Government of Puerto Rico, Department Transportation and

Public Works, Highway and Transportation Authority (Tren Urbano) provided

their programs for addressing unique safety and security certification challenges

during the major capital project development process.

San Francisco Municipal Railway (MUNI) offered its policies and safety design

criteria for integrating an entirely new line – its Third Street Rail Project – into its

existing operations. Dallas Area Rapid Transit (DART), San Francisco Bay Area

Rapid Transit District (BART), Washington Metropolitan Area Transit Authority

(WMATA), Tri-County Metropolitan Transit District of Oregon (Tri-Met), the

Los Angeles County Metropolitan Transportation Authority (LACMTA), and the

Santa Clara Valley Transportation Authority (VTA) all provided their programs

for planning, designing, and integrating major extensions into operations.

St. Louis Bi-State Development Agency (Bi-State) shared its program for

conducting hazard analysis during extension design and engineering, and tracking

the resolution of identified hazards through testing and acceptance. The

Massachusetts Bay Transit Authority (MBTA) and APTA have contributed safety

certification programs that support basic procurement processes, even when no

major acquisition project is underway.

Finally, several State Safety Oversight Agencies have contributed their program

requirements and standards for rail transit design and construction, including New

Jersey Department of Transportation (NJDOT), Utah Department of

Transportation (UDOT), the Oregon Department of Transportation (ODOT), the

Massachusetts Department of Telecommunications and Energy (DTE), the

Missouri Department of Economic Development, Division of Motor Carrier and

Railroad Safety (MCRS), the Colorado Public Utilities Commission (CoPUC),

and the California Public Utilities Commission (CPUC).

Page viii

Organization

To support implementation of practices that result in the design and construction of

transit projects that maximize safety and security performance within available resources,

the Federal Transit Administration (FTA), through its Joint Task Force on Safety and

Security Certification, has prepared this Handbook. The procedures described in this

Handbook enable transit management, the project team, and all others involved in the

project, to address safety and security requirements in a consistent and dedicated

program, throughout the development process.

This Handbook is organized in two chapters:

Chapter 1 – The Basics: Introduces the basic concepts of certification for safety

and security, and explains why, since its development only a few short decades

ago, this type of certification has become an integral part of effective project

management practice.

Chapter 2 – The Tools: Introduces three tools that support the safety and security

certification process:

• Well-defined project scope – to establish applicability of the certification

program for project elements and to encourage shared vision among the

project team

• Safety and Security Certification Plan – to establish roles and

responsibilities for the certification process and to define key activities

• 10-step Safety and Security Certification Methodology – to provide a

consistent process for verifying safety and security requirements

throughout all phases of project activity

Chapter 2 also provides sample forms to support implementation of the

certification program.

Appendices offer additional information on key topics discussed in the Handbook,

including:

Appendix A: Project Life Cycle Definitions

Appendix B: Useful Safety and Security Certification Resources

Appendix C: Resource Guide

Appendix D: Sample Design and Construction Specification Form and Directions

This Handbook should provide each member of the project team with a basic

understanding of the certification practice, demonstrating the importance of each

technical and managerial discipline to the overall safety and security mission.

Page ix

Page 1

Chapter 1

The Basics

As used in this Handbook, certification for safety and security is defined as:

the series of processes that collectively verify the safety and security

readiness of a project for public use

.

While this Handbook emphasizes rail transit projects – including both “new start”

systems and extensions to existing systems – its principles and practices extend to major

projects for all modes, including bus transit.

Depending on project scope and resources, the

process described in this Handbook should be

tailored to an appropriate level of specificity,

determined by the agency.

Certification, as used in this Handbook,

addresses conditions that could result in harm –

whether unintentional (safety) or intentional

(security). Application of safety and security

certification promotes an informed management

decision-making process in project design,

construction, testing, and initiation into revenue

service.

CERTIFICATION AS PART OF SYSTEM SAFETY AND SECURITY

The system safety and security discipline manages hazards and vulnerabilities throughout

the life cycle of a project, program, or activity through a committed approach to risk

management, where:

¾ a hazard is a condition or circumstance that could lead to an unplanned

or undesired event;

¾ a vulnerability is a characteristic of the system that increases the

probability of occurrence of a security incident; and

¾ risk is an expression of the impact of an undesired event or security

incident in terms of severity and likelihood.

Page 2

Certification for safety and security verifies application of this discipline for transit

projects. Through this process, hazards and vulnerabilities are translated into risks,

which are then analyzed, assessed, prioritized, and resolved, accepted, or tracked. Figure

1 presents this process as a continuous loop, providing for validation of decisions and on-

going evaluation to support further action. This process supports the consideration of

safety and security objectives during all activities of the dynamic and evolving project

management process.

Define Project

Translate Concept into

PMP

Set Expectations

Prioritize Tasks and

A

llocate Resources

Final Review

A

nalyze Hazards

Final Inspections

Manage Change Orders

Certification

Identify and analyze:

Hazards and

Vulnerabilities

Categorize & Prioritize

Identify Standards and

Requirements

Identify Controls to Prevent/

Mitigate

Establish Baselines

Implement Controls

Perform Conformance

Reviews

Start-up Testing

Integrated Testing

Develop/Implement

Controls

Perform Verification

A

ctivities

Implement Safe

and Secure

Pro

j

ect

Figure 1: Safety and Security Core Management Functions

Certification for safety and security is NOT contractual acceptance, defined as:

an action by an authorized representative of the transit agency by

which the transit agency assumes full or partial ownership of the

delivered project as complete or partial performance of a contract.

Contractual acceptance does not constitute safety and security certification, and safety

and security certification need not imply acceptance with respect to contract performance.

Page 3

SAFETY AND SECURITY CERTIFICATION BENEFITS

Many transit agencies self-certify the safety and security of their operations, subsequent

extensions and safety-significant modifications, prior to the initiation of revenue service.

This process is typically part of the agency’s existing program for system safety and

security, and is integrated into major projects through a Safety and Security Certification

(SSC) Program, documented in a Safety and Security Certification Plan (SSCP).

In certain instances, transit agencies have received benefits from the SSC during

engineering and design. SSC activities support analysis that reduces the need for

expensive retrofitting to correct hazards or vulnerabilities after the system is placed in

revenue service. Certification also typically supports improved integration of operational

considerations into project design, which offers the following opportunities:

• Improved functionality of system design

• Promotion of effective and efficient use of resources

• Reduction in work-arounds and change orders during construction

• Reduction in hazards in service and maintenance activities

In the event that accidents or major security incidents do occur, certification offers the

following benefits, which may be useful in legal and insurance proceedings:

• Hazards and vulnerabilities are identified and assessed, and documented action is

taken to resolve identified critical and catastrophic hazards as soon as possible.

• Appropriate codes, guidelines, and standards are reviewed to provide a basis for

safety and security consideration in the design criteria and specifications, and

drawings are in conformance with the design criteria.

• Facilities, systems, and equipment

are designed, constructed, built,

inspected, and tested in accordance

with applicable codes, standards,

criteria, and specifications.

• Necessary verification tests, safety

plans, security plans, operating

procedures, and rule books are

developed for operations.

• Personnel are trained and qualified to

respond to emergencies, and

emergency response organizations

are familiar with the transit systems

and its emergency procedures.

Page 4

TRANSIT AGENCY COMMITMENT

The self-certification that guides each agency’s SSC process reflects that agency’s

commitment to verify that its operation is free from unacceptable risk. This is a proactive

approach to safety and security with clear objectives to identify, anticipate, and control

adverse conditions before they occur. Through SSC, each transit agency typically makes

a commitment to:

Develop a policy formalizing management risk acceptance practices

for activities that affect the safety and security of the operational system

Identify and document the safety- and security-critical elements that

comprise the project

Specify and apply safety and security requirements, consistent with

approved risk management practices, to these elements, through the use

of design criteria, design manuals, contract specifications, and safety and

security analysis

Implement a dedicated program of hazard and vulnerability analysis

and tracking, which verifies, for each safety- and security-critical element,

the identification, evaluation, and resolution of all conditions with the

potential to result in death, severe injury, multiple injury, system loss, major

system damage, or major environmental impact

Implement a dedicated program of review to verify that safety and

security requirements are included in specifications, test plans, procedures,

and operational assessments for the project, and coordinated with all

transit departments that have responsibilities for the project

Implement a dedicated program of testing and evaluation, to verify that

safety- and security-critical elements, delivered to the agency, comply with

contract specifications, and that an acceptable level of operational

readiness and emergency preparedness exists among the transit

departments and personnel responsible for initiating the project into

revenue service

Issue written Certificates of Compliance (COC) for each safety- and

security-critical element, indicating that it meets established safety and

security requirements

Issue Project Safety and Security Certificate, along with a Final

Verification Report, verifying the project’s readiness for safe and secure

revenue service.

Page 5

RESPONSIBILITY FOR SSC PROGRAM

Ultimate responsibility for the development and operation of a safe and secure system

rests with the transit agency’s executive leadership. The transit agency provides direction

and guidance for the safety and security certification program. During project

development, implementation of the SSC program is often delegated to the project

management team, which verifies performance of all certification tasks.

In existing transit systems, certification for safety and security is often managed by the

safety and/or security manager (Certification Manager). For agencies with New Start

projects, the staggered approach required to support project development brings many

different participants with varying levels of responsibility over a period of several years.

In this environment, the SSC program should provide a consistent focus on safety and

security for all activities. This Handbook also uses the term “Certification Manager” to

address the range of personnel who may manage this process.

COMMITTEE INVOLVEMENT

Several safety and security committees, including the following, may support the SSC

program. In a transit agency, the functions described below may be combined, or may be

performed by individuals rather than committees.

Safety and Security Review Committee (SRC): Many transit agencies have found it

beneficial to create a Safety and Security Review Committee -- or equivalent multi-

disciplinary group -- to oversee the conduct of safety and security efforts for the project,

directly accountable to the transit agency’s executive leadership. The SRC is typically

chaired by a full-time System Safety and/or Security Manager or the Certification

Manager. The SRC is typically comprised of senior management personnel, or their

designees, who represent the major project areas and activities. The SRC oversees the

SSC program and directs resolution of identified hazards. The SRC discusses ongoing

safety and security concerns; reviews and approves certification activities; and resolves

issues among the project team and with the agency’s executive leadership.

Fire-Life Safety Committee (FLSC). This Committee is to serve as a liaison between the

transit agency, fire jurisdictions, and emergency response agencies. The FLSC may be

comprised of local and state fire jurisdictions, local emergency response agencies, transit

operations, safety, security, construction and design managers, along with transit

management staff and the general design consultant. The FLSC reviews standards and

safety-related designs and tests to verify fire-life safety code and regulation compliance.

In addition, the FLSC addresses preparedness issues and reviews variances.

System Change and Operations Review Committee (SCORC). This Committee’s

responsibilities include planning and coordinating operational training, simulating

revenue service conditions, and developing pre-revenue plans, rules, and procedures for

revenue service. Prior to revenue service, the SCORC reviews procedures, manuals, and

other documents that form the basis for certifying compliance to safety and security

requirements for systems and fixed facilities. The SCORC may also be responsible for

review and concurrence of proposed changes and/or revisions to the project design.

Page 6

APPLICATION OF THE PROJECT LIFE CYCLE

Many transit agencies use a standard life cycle framework to manage transit projects,

such as the one shown in Figure 2 below. This life cycle defines the events, procedures

and tasks that take place within the project. Each life cycle phase may conclude with a

review, enabling management evaluation. Appendix A provides a brief description of

activities typically performed in each life cycle phase.

Advancement through this process is based on a project's readiness to progress to

subsequent phases. Transition from one life cycle phase to the next phase constitutes a

MILESTONE CONTROL for all major project elements, including safety and security.

PLANNING

PRELIMINARY

ENGINEERING

MILESTONE

CONTROL

FINAL

DESIGN

CONSTRUCTION

INTEGRATED

TESTING

PRE-REVENUE (INTERIM)

OPERATIONS

OPERATIONS

Figure 2: Typical Transit Project Life Cycle

Page 7

SAMPLE ACTIVITIES

A sample listing of typical activities performed during the certification process is

presented in Figure 3, below. Figure 3 categorizes key activities for each of the project

life cycle phases:

PLN – Planning

PE – Preliminary Engineering

FD – Final Design

CON – Construction

INT-TEST – Integrated Testing

PRE-REV – Pre-revenue (Interim) Operations

OPS – Operations

Checks (9) indicate the initiation of the activity, and shaded arrows () indicate ongoing

performance.

In managing these activities, Certification Managers typically work closely with the

project team to address the following:

• Roles and responsibilities for safety and security (at all levels of the organization)

• Required resources and project schedule for safety and security activities

• Procedures and programs to ensure safety and security integration into design,

construction, testing and acceptance, and start-up activities

• The process for the identification and effective communication of safety hazards

and security vulnerabilities associated with the operational phase of the transit

project

• The process for sound decision-making which integrates the results of system

safety and security activities into the requirements and specifications for the

project

Figure 3 is a representative sample only. The scope of each project should be considered

to determine the tasks that are appropriate.

Page 8

TASK

9

Develop Safety and Security Policy

9

Assign SSC Responsibilities

Establish Safety and Security Committees

9

Identify Existing Safety and Security

9

Requirements for Acquisition Process

Develop Safety and Security Certification

9

Plan

Identify Safety and Security Certifiable

9

Elements & Items

Initiate Project Documentation System

9

Perform Preliminary Hazard and

9

Vulnerability Analysis

Prepare Safety and Security Design Criteria

9

Integrate Operations and Maintenance

9

Requirements into Design

PLN

Develop Design Criteria Conformance

9

Checklists

Perform Safety and Security Design Reviews 9

PE

Perform Additional Hazard and Vulnerability

9

Analyses (as applicable)

FD

Implement Hazard and Vulnerability

9

Resolution and Tracking

Verify Design Criteria Conformance

9

CON

Checklists

Identify Safety and Security Requirements

for Test Program Plans, Integrated Testing

INT-

9

TEST

and Operational Readiness

Develop Specification Conformance

9

PRE-

Checklists (Construction)

REV

Complete Specification Conformance

9

Checklists

OPS

Issue Permits and Certificates (as applicable)

9

9

Complete Integrated Tests

Safety and Security Review of Engineering

9

Change Orders & Waivers

Complete Operations & Maintenance Plans,

9

Procedures and Training

Complete Operational Readiness Review

9

(including work-arounds)

Issue Final Safety and Security Certification

9

Issue Final Safety and Security Verification

9

Report

Figure 3: Project Development Safety and Security Activities

Page 9

PROJECT TEAM SUPPORT FOR THE SSC

Each member of the project team has a role in safety and security certification. While the

Certification Manager has primary responsibility for SSC management, the tasks required

to perform the SSC include many functional disciplines on the project team. As indicated

in Figure 4 below, the Certification Manager should support a coordinated effort that

brings the capabilities and resources of the design team, the construction team, the

acceptance and testing team, and the activation team to the performance of SSC

activities.

Transit Executive

Management

TRANSIT PROJECT

Project Manager and

Management Team

Design

Construction

Testing

Activation

(Start-up)

Safety and

Security Policy

Roles and

Responsibilities

for Safety and

Security

Resource

Allocation,

Schedule Control,

Decision-making

Safety & Security

Certification

Management

Figure 4: Contributions of Project Team to SSC

-Hazard Analysis

-Vulnerability

Assessments

-Safety/Security

Design Criteria

-Safety/Security

Design Specification

-Design Conformance

Certification

-Conformance with

Safety/Security

Specifications

-Management of Change

Orders/Deviations

-Construction Safety

-On going Hazard

Resolution

-Construction Testing

-SSC-related Tests

-Construction

Conformance

Certification

-On going Hazard

Resolution

-On going Vulnerability

Resolution

-Integrated Testing

-Integration Testing

-On going Hazard

Resolution

-Rulebook

-Procedures

-Training

-Drills

-Readiness

-Operation Turnover

-Final Safety Certification

Page 10

MANAGING DOCUMENTATION

To manage the SSC program, a documentation system is strongly recommended. This

system may contain documents pertaining to the certification process. The project filing

system may fulfill this requirement, or may be supported by an additional system.

In general, safety and security certification documentation should be maintained for the

life of the agency. Security information and other sensitive information should be

protected using agency policies and procedures.

An important part of the safety certification process is keeping transit management

informed of the status of the program. To ensure that executive leadership is informed,

periodic reports are prepared. The reporting period may change from time to time,

dependent upon activity levels and project priorities.

SAFETY AUDIT PROGRAM

tech tip

Throughout the verification effort, audits should be conducted on a

periodic basis, by a management team independent of the program.

Audits should verify that all participants in the design conformance

and testing/acceptance processes are reviewing compliance with

safety and security requirements and appropriately documenting this

conformance. Other activities to be assessed include the following:

Linked

worksheets,

supported in a

• The status of each safety task

database, can

• Compliance with program milestones and safety program

reduce document

milestones

preparation time

• Schedule incompatibilities that require remedial corrective

and promote

consistency from

action

project phase to

• Action to track and implement positive corrective actions

project phase.

where deficiencies are revealed

• Project team activity to support the SSC program

• Configuration management

Page 11

Chapter 2

The Tools

SCOPE OF THE SSC PROGRAM

The SSC program typically encompasses the equipment, operating and maintenance

plans, facilities, and procedures for the following three categories:

• Systemwide Elements – may include the passenger vehicles, catenary, traction

power, train control system, voice and data communications, CCTV, grade

crossing and traffic control system, intrusion detection system, traction power

substations, central instrument houses, track, fare collection, supervisory

control, fire protection and suppression systems, and auxiliary vehicles and

equipment.

• Fixed Facilities – may include stations and shelter stops, pedestrian bridges,

yard and shop, structures, and the control center. Equipment installed in

stations or shelter stops such as HVAC, escalators, elevators is also considered

part of the facility.

• Plans, Procedures, and Training – may include items such as emergency

preparedness plans, security plans and procedures, training programs, rule

books, and standard operating procedures.

When properly scoped, the SSC program will:

• Develop, document, and communicate safety and security criteria to guide design,

engineering, and specification for the transit project

• Identify safety and security critical issues and develop practical and cost-effective

requirements to support their resolution

• Use hazard and vulnerability analysis to evaluate the impacts of all deviations

introduced into the system in the form of engineering change proposals,

construction change orders, work-arounds and other temporary measures prior to

the initiation of revenue service

• Develop management mechanisms to track and control the incorporation of safety

and security into the transit project.

Page 12

SAFETY AND SECURITY CERTIFICATION PLAN

The Safety and Security Certification Plan is a basic tool used by the transit organization

to assist in managing an effective certification program. The SSCP provides the formal

basis of understanding and agreement among all members of the project team regarding

how the program will be executed. The SSCP typically describes the process through

which the transit agency activity will provide documented verification that:

• A certifiable elements list is developed

• Safety and security design criteria are developed to identify concerns

appropriate for the project

• A design checklist is developed and completed to verify compliance of

contract specifications with the safety and security criteria

• Construction checklists are developed and completed to verify that facilities

and systems are constructed, manufactured or installed according to design

• Integrated tests are identified that need to be monitored for safety and security

• Training classes are provided to transit operations and maintenance staff that

address safety, security, and emergency preparedness

• Operations and maintenance manuals are provided to, or developed by, transit

operations and maintenance staff

• Operations and maintenance staff are trained on rules and procedures.

• Public safety personnel (i.e., fire and police) are trained to manage their

activities safely in the transit environment

• Emergency drills are conducted for identified transit emergencies that may

occur on the project

• Hazard and vulnerability identification and resolution are performed with

tracking for resolution and/or acceptance throughout the project

• The “Certificate of Safety and Security” is issued to verify that the transit

project is safe and secure for revenue service

• The Safety Certification Verification Report is prepared, and transmitted, as

appropriate to management and oversight personnel

• The transit project successfully complies with identified safety and security

requirements.

Page 13

A typical Table of Contents for the SSCP follows:

SSCP SAMPLE TABLE OF CONTENTS

==============================================================

Section 1: Introduction

• Authority

• Introduction

• Purpose

• Objectives

• Definition

• Responsibility

• Scope

• Certification Revisions

Section 2: Program Management

•

•

Project Team

Safety and Security Review

Committee

Fire/Life Safety Committee

System Change and Operations

Review Committee

• Hazard Identification and

Analysis

• Threat and Vulnerability

Assessment

• Resolution Process

• Open Items List

Section 5: Certificate of Conformance

•

•

Section 3: Certification Process and

Procedures

• General

• Certifiable Elements

• Criteria Conformance Checklist

• Specification Conformance and

Operational Readiness Checklists

• Tests & Inspections

• Integrated Testing and Integrated

Test Permit

• Plans and Procedures

• Training Programs

• Emergency Drills

Section 4: Hazard and Vulnerability

Management

• General

• Responsibility

• Issuance

• Exceptions

Section 6: Documentation

• Requirements

• Responsibilities

Section 7: Reporting Requirements

• Periodic Reports

• Final Certification

• Final Verification Report

Page 14

STEPS IN THE SSC METHODOLOGY

The remainder of this Handbook explains the SSC methodology, providing a brief a description

of each step, and presenting sample forms to support the certification process. Appendices B and

C provide additional references for further information on certification activities. Appendix D

provides a sample Design and Construction Specification Form and directions for completion.

Safety and Security

Certification

STEP-by-STEP

The following steps typically comprise the SSC methodology:

Step 1: Identify Certifiable Elements

Step 2: Develop Safety and Security Design Criteria

Step 3: Develop and Complete Design Criteria Conformance Checklist

Step 4: Perform Construction Specification Conformance

Step 5: Identify Additional Safety and Security Test Requirements

Step 6: Perform Testing and Validation in Support of the SSC Program

Step 7: Manage Integrated Tests for the SSC Program

Step 8: Manage “Open Items” in the SSC Program

Step 9: Verify Operational Readiness

Step 10: Conduct Final Determination of Project Readiness and Issue Safety and

Security Certification

Page 15

STEP 1: Identify Certifiable Elements

The first step in the SSC methodology is to identify the elements that need to be certified for the

transit project. Safety certifiable elements include all project elements that can affect the safety

and security of transit agency passengers, employees, contractors, emergency responders, or the

general public. These elements define the scope of the project’s certification program. Prior to

the initiation of revenue service, a Certificate of Compliance will need to be issued for each

identified element.

Certifiable elements are composed of numerous items. These items make up the whole of the

major element and require individual safety and security verification before the major element is

verified as safe and secure for use. The listing of these items for a major element is typically

referred to as a Certifiable Item List (CIL).

The process of “breaking down” certifiable elements into CILs typically occurs simultaneously

with the project team’s engineering effort. As depicted in Figure 5, the engineering breakdown

structure supports identification of CILs for each certifiable element – particularly for complex

systems (train control upgrades, new vehicles) and projects with a significant emphasis on

integration into an existing operation.

Specific certifiable items on the list are dependent on the particular element. In addition, listing

of a certifiable item may need to be duplicated a number of times within a certifiable element.

For example, each light rail vehicle requires individual verification, and each is tracked as a sub-

element of the

element “Light Rail

Vehicle.” Similarly,

there are a number of

duplicate certifiable

items for train s

ignals,

Subsystem 1

Subsystem 2

Subsystem 3

TOTAL SYSTEM

Assem bly 1a

traction power, tr

ack,

Assem bly 1b

and other elements

.

Each element may

Subassem bly

1c.1

Subassem bly

1c.2

Subassem bly

1c.3

Com ponent

1c.3.1

Component

1c.3.2

Com ponent

1c.3.3

Part 1.c.3.3.b

Part 1.c.3.3.c

Part 1.c.3.3.a

Figure 5: Engineering Breakdown Structure

Assem bly 1c

also be divided into

sub-elements

equivalent to a

particular section of

the alignment of the

light rail system bein

g

verified.

Page 16

Figure 6 presents major groupings of certifiable elements and sub-elements for a rail transit

project. This is a sample listing provided for illustrative purposes only. Each agency must

determine those elements requiring safety and security certification based on its own policies and

the scope of the project.

SAMPLE CERIFIABLE ELEMENTS AND SUB-ELEMENTS LIST

SYSTEMS

CIVIL INSTALLATIONS

VEHICLE TRACK AND STRUCTURES

• Carbody • Right of Way

• Coupler • Track

• Doors, Door Operators and Controls • Aerial

• Trucks and Suspension • At-grade

• Propulsion • Underground

• Braking • Barriers and Warnings

• Operator’s Cab and Controls

• Communication Equipment

YARD AND SHOP

• Mobility Lift

• Lighting

• HVAC

• Fire/Flammability/Smoke Emissions

• Electrical Safety Provisions

• Vehicle Movement Provisions

• Track and Appliances

• Building (Occupancy)

SIGNALS

• Fire System

• Lifts/Elevator

• Interlocking Circuits/Equipment

• Mainline Controls and Indications

STATIONS/PARKING LOTS

• Grade Crossing Warning Devices

• Yard/Mainline Interface

• Track Signals

• LRT Signals

• Signal Indications

• Train Protection

• Platforms

• Handicapped Access Provisions

• Elevators and Escalators

• Illumination

• Electrical Grounding

SIGNAGE

COMMUNICATIONS

PROCURED ITEMS

• Radio System

TRAFFIC SIGNAL CONTROLLERS

• Operations Control Center

MOBILITY IMPAIRED LIFTS

• SCADA

TRACTION POWER SUBSTATIONS

• Fire Department Communications

TICKET VENDING EQUIPMENT

• Security Communications

• Security Systems

PLANS, PROCEDURES AND TRAINING

• Fire Systems

• Public Address Systems

TEST PLANS

TRACTION POWER SYSTEMS

• Acceptance Tests

• Integrated Tests

• Enclosures

• Pre-Revenue Tests

• High Voltage Switchgear

• AC to DC Conversion

OPERATING AND MAINTENANCE PROGRAM

• DC Switchgear

• Batteries and Accessories

• Catenary

• Stray Current Protection

Standard Operating Procedures (SOPs)

Emergency Operating Procedures (EOPs)

Manuals and Rulebooks

Training and Certification (if applicable)

Local Responder Training

Emergency Preparedness

Figure 6: Sample Certifiable Elements and Sub-elements List

Page 17

Figure 7 illustrates how certifiable elements are addressed in the project. At each stage of the

process, for each certifiable element, conformance with project safety and security requirements

is verified; certified through issuance of certificates prior to revenue service; and documented in

a Final Verification Report.

Certifiable

Element

PROJECT PERFORMANCE

Construction Rules and

Training and

Exercises

Conformance

Specification

Conformance

Testing,

Inspection

Conformance

Risk Resolution

Conformance

Procedures

Design Criteria

Conformance

Conformance

CERTIFICATE OF CONFORMANCE FOR EACH

CERTIFIABLE ELEMENT

PROJECT SAFETY AND SECURITY CERTIFICATE

FINAL

VERIFICATION

REPORT

Figure 7: Certifiable Elements and the Certification Process

N

E

E

D

PER

F

O

R

M

AN

C

E

Page 18

STEP 2: Develop Safety and Security Design Criteria

Design is an iterative process. Safety and security are addressed during project design through

identification of safety and security design criteria for each certifiable element. Safety and

security design criteria are intended to provide guidance to t he design team to support the

definition of systems, sub-systems and components, the d evelopment of performance

requirements, and the final specification of the engineered s ystem.

Whenever possible, reference to their identification and

documentation should be included in the procur ement package for

design services.

As indicated in Figure 8 below, safety and security design

criteria are often generated from:

1. The technical specifications from previous contracts

2. Existing agency design and performance criteria

3. Transit agency “lessons learned” from operating e xperience

4. The results of hazard and vulnerability analysis

SPECIFICATION

C

RI

T

E

RI

A

DESIGN

PROCESS

5. Transit industry safety and security practice and reports

6. Applicable safety and security codes, standards, and regulations defined by Federal, state

and local agencies and standards boards and organization s

Experience

Project material

selection

Resources

available

y Dollars

y People

y Time

Criteria

EVALUATION

Standards and codes

y MIL STDS/

y Commercial stds

y ANSI STDS

y ASTM STDS

y NFPA Codes

y BOCA

y PROJECT Guidelines

Specification

Constraints

Emergency

planning

Figure 8: Safety and Security Specification Development Inputs

Page 19

Safety and security design criteria may be consolidated into a single manual or list for the

project, or referenced as part of project development for each certifiable element. A

representative process for incorporating these criteria into the project design process is illustrated

graphically in Figure 9 below:

Project Definition

and General

Requirements

(Alterntatives

Analysis)

Identification of

Safety and Security

Codes, Standards,

Requirements

Prliminary Hazard

List and Analysis

Preliminary Project

Description and

Component

Identification

SAFETY AND

SECURITY

DESIGN

CRITERIA

DESIGN

Preliminary

Specifications and

Drawings

System Safety and

Final Project

Specifications and

Drawings

Design

Approval

Security Analysis

Design Reviews

Figure 9: Safety and Security Design Criteria and Project Specification

RESOURCES: FTA’s Hazard Analysis Guidelines for Transit Projects and APTA’s Manual

for the Development of Rail Transit System Security Program Plans both provide additional

information on the role and management of analysis in project design. These documents

are available for download on FTA’s web site: www.fta.dot.gov (click on “Safety and

Security”) and APTA’s web site: www.apta.com.

Appendices B and C also contain useful references and sample codes for development of safety

and security design criteria.

Page 20

STEP 3: Develop and Complete Design Criteria Conformance Checklist

During design, the project team may begin identifying criteria requirements for certifiable

elements and items. This process involves the creation of a checklist for each certifiable element

to record requirements generated from safety and security design criteria. These checklists –

referred to as Design Criteria Conformance Checklists – provide a format to verify compliance

with identified safety and security requirements.

In the certification process, contract specifications, design criteria, applicable codes, and industry

standards may constitute this verification. For example, some of the requirements in contract

specifications may be used as verification, such as maintenance manuals, subsystem hazard

analysis, and factory test reports. Other requirements may not take the form of specific

deliverable documents, but require verification.

Following initial development, the Design Criteria Conformance Checklist is submitted to the

appropriate personnel for review and comment. A sample Design Criteria Conformance

Checklist is provided in Figure 10.

During development of these checklists, it may also be necessary for the project team to

reference safety and security requirements for use in design reviews and during inspections or

tests. Identification of these activities provides an opportunity for the entire project team to

assess the status of the SSC program through the following activities:

• Briefings on major safety and security program milestones, including hazard

identification and analysis, vulnerability assessments, required test, inspections and

procedures, and special issues not yet resolved

• Identification of subsystem, component, and software safety activities as well as

integrated system level activities (i.e., design analyses, tests, and demonstrations)

applicable to the SSC program but specified as tasks for which other transit agency or

contractor personnel or functions are responsible

• Delivery of reports and analyses documenting the consequences of specific project

decisions for safety and security levels, including recommendations

• Identification or presentation of evaluation results relating to requests for deviation from

approved baseline designs, procedures, or practices

• Scheduling coordination and group priority setting for safety activities to be addressed in

the next project phase

• Status of compliance with identified regulations.

Finally, during this phase of the safety certification process, it is important to identify the process

to be used for the management and tracking of “open items.” The term “open items” refers to

items that have not been verified for conformance with design requirements, as well as

DESIGN VERIFICATION APPROVAL

_______________________________________________________________________________

Name Signature Date

____________________________________

Organization

Page 21

unresolved safety or security issues. As the project proceeds through design to construction to

start-up, reviews are often performed to verify that change proposals and deviations from the

approved baseline design do not degrade the level of safety and security of the system to

unacceptable levels. “Open items” are often addressed during these reviews.

Design Verification for Safety and Security Certifiable Items

Element:________________________ Page___________ of ____________

Sub-Element:____________________ Prepared by:____________________

Revision:________________________ Date:__________________________

Contract Number:_________________

Status Means of Verification - Design

C = Compliance

N = Noncompliance

P = Partial Compliance

S = Submittal

D = Design

Item

No.

Description Safety Design Criteria Design Cross

References

Design Verification Means of

Verification

Status Initial Date

NOTES/EXCEPTIONS:

Figure 10: Design Criteria Conformance Checklist

Page 22

STEP 4: Perform Construction Specification Conformance

The construction specification conformance process is used to verify that the as-built facilities

and systems incorporate the safety and security-related requirements identified in the

specifications and other contract documents, including approved changes since the final design.

This checklist should be viewed as the “other half” of the Design Criteria Conformance

Checklist, because it (1) identifies the tests and verification methods necessary to ensure that the

as-built configuration contains the safety-related requirements identified in the applicable

specifications and other contract documents, and (2) provides documentation that the delivered

project meets these requirements. The Specification Conformance Checklist is the “work horse”

of the SSC process.

Once the checklist format is completed, verified checklists are forwarded to appropriate staff for

review and comment. Documentation supporting verification of the safety requirement should be

available for review by the project team. For facilities and systems, certifications, inspector

reports, job photos, or other evidence may be submitted as documentation. Any contractor

submittal used for verification needs to be approved, typically by the resident engineer.

Safety and security requirements not verified by available documentation or demonstration

should be tracked to resolution. As mentioned in Step 3, the management or resolution of open

items should result through project team’s use of the Specification Conformance Checklist. This

checklist provides those responsible for decision-making a tool to review the status of open items

resulting from deviations to the approved design, work-arounds, change orders, and other

temporary measures.

Three Specification Conformance Checklists, (two with sample entries), are presented below.

Figure 11 identifies an excerpt from a specification checklist to demonstrate the types of issues

typically encountered for an at-grade light rail station. Figure 12 provides sample documentation

of non-compliance regarding safety and security requirements for right-of-way signage. Figure

13 provides a sample checklist that can be used to document both design and construction

conformance. Directions for completing this form are provided in Appendix D. This type of

checklist is easily incorporated into an automated information system, to support SSC program

tracking and documentation requirements.

Some transit agencies may choose to compile supporting verification documentation for each

certifiable element in separate notebooks. Some guidelines that may be used in the verification

process include the following:

1. Use documentation that directly and succinctly verifies the safety and/or security

requirement

2. Exclude irrelevant or redundant information

3. For large contract submittals, include representative information only

4. Highlight specific detail from approved contractor submittals and other verification

documentation to aid the review process

8

Page 23

Contract # C-60

Certifiable Element: E-1 Subsystem: Station / At-Grade

No. Safety

Requirement

Standard/

Source

Compliance:

Specs, As-Built

Dwgs;Pg#

Y N N/A Means of

Verification/

Remarks

Note: NFPA = National Fire Protection Association, UFC = Uniform Fire Code

1 Construction

Material

(Type I or II)

NFPA 130/2-2,

UFC-Chap. 6,

Design Criteria

Manual, Chap. 8

Specs 03462, 05130,

05300, 07410

X Visual Verification

2 Electrical

Requirements

- General

NFPA 70,

NFPA 130/2-4.1,

Design Criteria

Manual 28

Specs 16001, 16030,

16111, 16120, 16130,

16490, 16450, 16470,

16500, EC1-0003-

0005, pgs 659-661

X

Visual Verification

3 Identification of

Breakers

Design Criteria

Manual 28.7.2,

NFPA 70

Specs 16040, 16470

EC1-0003-0005, pgs

659-661

X

Visual Verification

4 Passenger Egress NFPA 130/2-5

and

Appendix C

Dwg AC2-0004, pg

585

X Visual Verification

5 Passenger Access Design Criteria

Manual 19.2.2

Dwg AC2-0004, pg

585

X Visual Verification

6 Emergency

Lighting

Design Criteria

Manual 26.5.4,

NFPA 130/2-6

Dwg AC2-0004, pg

585

X

7 Automatic Fire

Detection

Design Criteria

Manual 27.4,

NFPA 130/2-7.1.5

N/A X

Emergency

Communication

NFPA 130/2-7.2;

3.1.5

and 8-7

AC2-0005-0007, pgs

586-588;

EC2-0003-0005, pgs

659-661

X

Pay phones need to

be connected for

emergency

communication

devices. Both

phones working

9/21/01 – Close.

Figure 11: Sample Specification Conformance Checklist

A. Sign not

installed at

proper

location at

969+74.

X

B. Sign

removed

and

damaged at

955+50 by

contractor.

X

C. Signs

installed at

wrong

location at

station at-

grade

crossing.

X

F. Sign

installed at

wrong

location at

station at-

grade

crossings.

X

G. Sign

removed on

track 2 side

at 952+00,

station.

X

Certifiable Element: E-4

Contract: Contract-01

Revision Date: 03-27-2002

Prepared By: Joe Safety

Page 24

Light Rail Transit

LRT Buildout Phase 1

Safety/Security Certification Checklist

Subsystem: Trainway - Surface Design Phase

Certified – 8/24/00

Construction /

Installation / Test

SSCRT Certified

Item

Safety

Requirement

Standard

/ Source

Compliance,

Specifications,

or Drawings

Remarks

Status

Yes

No

N/A

Remarks

(Date

Verified)

Status

Yes

No

N/A

1 ROW Safety /

Warning

Signage

NFPA

130/3-1.3

Conformed Spec

2847,

Conformed

Dwg(s) RC9-

4001 to 4007

pp. 93-99

X

Figure 12: Sample Specification Conformance Checklist with Non-compliance

Certifiable Element:_____________

Checklist Type: Master:___________ _ Sub:___________

Sub-Element:____________

Contract Number:_____________

Safety:___________ __ Security:________________

Specification/Drawing Reference:_

Document Control Number:

Revision:__

Page 25

Means of Verification - Construction

M = Measurement

T = Test

V = Visual Inspection

NOTES OR RESTRICTIONS:

re 13: Sample Design and Construction Conformance Checklist with Directions

______________

__________________

_________________________

Design Verification Construction Verification

Item

No.

Description Design

Cross

Reference

Status Initial Date Means of

V

erification

Status Initial Date Means of

Verification

FINAL DESIGN VERIFICATION

Name and Organization:______________________________________

Date: _____________________________________________________

Approved By: _______________________________________________

Date: _____________________________________________________

FINAL CONSTRUCTION VERIFICATION

Name and Organization:_____________

Date:______________________________

Approved By:______________________

Date:______________________________

Figu

Status

C = Compliance

N = Noncompliance

P = Partial Compliance

Means of Verification - Design

S = Submittal

D = Design

Page 26

STEP 5: Identify Additional Safety and Security Test Requirements

Contractor and integrated testing requirements should be reviewed for safety and security

considerations. Contractor testing, as required by the contract specifications, verifies the

functionality of the involved system or equipment. Integrated testing verifies the functional

interface between different equipment or systems. Both contractor and integrated testing are

subject to certification. Certification of contractor testing may be verified in the Specification

Conformance Checklist, or combined with integrated testing in a test program certification or by

other acceptable means.

The need for additional tests, however, may arise for various reasons throughout the project. To

request and record the performance of additional tests, the project team may prepare a formal

Test Description Sheet and submit it to the appropriate organizational unit managing the Test

Program Plan. A sample Test Description Sheet follows:

REQUIRED SAFETY AND SECURITY

TEST DESCRIPTION SHEET

Test Name:

Test Procedure:

Contracts Involved:

Test Objectives:

Test Description:

Test Prerequisites:

Resources

Required

Personnel:

Equipment:

Facilities:

Time Required:

Figure 14: Required Test Description Sheet

Page 27

STEP 6: Perform Testing and Validation in Support of the SSC Program

From the initial stages of the construction development phase, test reports and other

documentation will be submitted to the agency as a result of Design Qualification Tests

(Factory); Production Verification Tests (Factory); Construction Inspection Tests; and

Installation Verification Tests (QA/QC). Safety/security-related test results should be

documented, as appropriate, in the Specification Conformance Checklist.

Appropriate documentation supporting verification of the safety and security requirements

should be submitted or available for review by the project team with its location clearly

identified. The SSC should identify responsibilities for control and lifecycle of all certification

documentation. Those personnel responsible for safety and security certification should work

closely with all involved in this process to achieve full access to the testing and results. This

process is illustrated below:

Identify

Test

Requirem e

nts

De ve lo p

Testing

Sequence

Prepare Test Plans and

Procedures (Include Em ergency

Procedures)

Com plete

and Close-

out Test

Is Pr oce dur e

Acce ptable?

Was Procedure

De ficie n t ?

Was Test

Acce ptable?

NO

YES

Pre pare

Modify

Test

Equipment

Schedule

Perform

and

NO

Docu m e n t

Tests

YES

Re vie w and

Ev a lu a t e

Data

NO

YES

Analyze

Cause or

Failur e

Re vie w

Test Plans

and

Procedures

Figure 15: Test Program Planning Process

Page 28

STEP 7: Manage Integrated Tests for the SSC Program

Integrated tests are any tests or series of tests, which require the interface of more than one

element and are designed to verify the integration and compatibility between system elements.

Pre-operations tests are those tests that require acceptance of all systems and are designed to

verify the functional capability and readiness of the system as a whole. These tests are not

necessarily required by contract specification, but are required as part of the test program plan to

ensure that all systems are functioning safely prior to the system being placed into operation.

Test result reports form the basis for meeting the safety requirements.

Prior to developing a plan for integrated testing, transit agencies typically assess both the scope

of the project related to existing or planned operations and the initial safety and security

requirements. In specifying the tests, transit agencies often identify a minimum level of safety

and security conformance that should be met, as well as the measurables used to assess this

conformance. This minimum level varies from project to project, and is dependent upon the

level of integration and the nature of the tests to be performed. It is important to note that transit

agencies should review test procedures, themselves, for potential hazards. The transit agency

may also want to develop emergency plans to prepare for a potential critical or catastrophic test

failure.

The transit agency may assign a “System Integration Manager” or equivalent personnel to be

responsible for test management. This manager is often supported in test planning, test procedure

development and test performance by Operations, Maintenance and the Safety and Security

Review Committee. The organizational group designated to manage start-up activities also

receives support from these groups in scheduling facility access and arranging for human

resources to conduct and witness the test.

Copies of all applicable tests and inspection reports should become part, of or be referenced in,

the formal SSC files. A sample integrated test description sheet is provided below.

Page 29

SYSTEM INTEGRATION TESTING

TEST DESCRIPTION SHEET

Test Name: LRV Clearance Test

Test Procedure: SI – 101

Contracts Involved: C510 - Civil, Track and Landscaping

C540 - Stations and Park and Ride

S510 - OCS and LRT Signal System

Test Objectives: Verify that there is adequate clearance between the LRV and

the equipment and facilities along the mainline.

Test Description: Tow a vehicle, equipped with foam extenders to represent the

Dynamic envelope, over the mainline right-of-way with the

pantograph retracted. Confirm clearances are as specified.

Test will be repeated when Low Floor Vehicles are available.

Test Prerequisites: Equipment and facilities installed along mainline right-of-way.

Personnel: Test Coordinator

Test Controller

Rail Activation

Maintenance Engineering

CM Representative

Vehicle Operator

Equipment: Hi-Rail Vehicle Mover

Light Rail Vehicle

LRV Foam Extenders

Measuring Tape

Radios (4)

Facilities: Both mainline tracks

Time Required: 8 to 12 hours

Figure 16: Sample Integrated Testing Sheet

Resources Required

Page 30

STEP 8: Manage “Open Items” in the SSC Program

As the certification proceeds, open items will be identified and will need to be managed.

During pre-revenue testing and start-up activities, requests for work-arounds and

temporary permits of occupancy/notices will be made. The SSC program must have the

tools available to ensure that the safety and security designed into the system are realized

in the delivered, tested, and validated project.

A Safety Critical Items List (SCIL) can be used to track the status and/or resolution of

those open items identified with the potential to result in harm. Depending on definitions

used for the project, these items may represent catastrophic and critical hazards and

vulnerabilities, defined as Category I and Category II hazards using Checklist Number 7

of the American Public Transportation Association’s Manual for the Development of Rail

Transit System Safety Program Plans and also referenced in the FTA Hazard Analysis

Guidelines. Category I and II hazards may require additional analysis to be performed to

ensure that mitigation measures adopted to eliminate or minimize their risk will be

effective in doing so before revenue operations can commence.

The SCIL, or other log, can also support tracking of exceptions or restrictions in those

situations when a safety certifiable element/item cannot meet design specification with

the initiation of revenue service. These exceptions must be accompanied by acceptable

operational work-arounds, if the item is critical for the commencement of revenue

operations. The work-arounds should proscribe operational policies and procedures that

ensure safe system operations, even though certification requirements are not completed.

It is important that safety, security, and operations representatives and the project

manager are equally aware of the accepted measures and the item is tracked to resolution

(it should be noted that in some cases accepted measures may be permanent). The figure

below presents a sample close-out report for significant items.

STATUS REPORT FOR CLOSE-OUT

Item No. System

Element:

Sub-system: Reference

Information:

Date:

Description of Condition: Required Controls:

Status: Responsibility: Approved:

Name: Department:

Figure 17: Sample Close-out Report

Page 31

STEP 9: Verify Operational Readiness

Operational readiness includes activities to verify the following:

• Applicable operations, maintenance, and emergency rules, procedures, and plans

have been developed, reviewed, and implemented

• Manuals, showing how to operate and maintain systems equipment and facilities,

have been developed, reviewed, approved, and accepted by the project team

• Safety/security-related training for operations and maintenance personnel has

been developed, performed, and successfully completed by all personnel as

required

• Emergency training has been developed, performed, and successfully completed

by all personnel as required, including public safety personnel (if appropriate)

• Emergency drills and training have been conducted with outside agencies

o To familiarize and train response personnel in emergency procedures

o To evaluate response procedures

o To identify improvements to response procedures before a real emergency

occurs

o To maintain an adequate level of preparation for a possible emergency.

During the pre-operations phase of the system, the procedures and plans are tested for

effectiveness under simulated operating conditions for normal, abnormal, and emergency

situations. Verification for these activities often includes signatures by the appropriate

officials or employees on all procedures, rulebooks, and training necessary to support

operation and maintenance of the system. The operating and maintenance procedures and

plans are judged as meeting the verification requirements or are recommended for

modification.

In addition, during this period, the project team should conduct a final “walk-through

inspection” of completed facilities and systems.

Page 32

STEP 10: Conduct Final Determination of Project Readiness and Issue Safety and Security

Certification

Before revenue service begins, prior to completing its formal certification, the project

team and supporting committees should review all safety and security certification

documentation to determine if any outstanding items remain.

Approval of certifiable elements occurs when work has been completed in conformance

with criteria and hazards have been reduced to an acceptable level. Any remaining work-

arounds affecting a certifiable element require a hazard management plan to be initiated

that will analyze the hazard and control the risk to an acceptable level for a defined

period of time. The hazard management plan must include any Category I and II hazards

to ensure that they have been resolved or controlled to an acceptable level prior to

entering revenue service.