Rochester Institute of Technology Rochester Institute of Technology

RIT Digital Institutional Repository RIT Digital Institutional Repository

Theses

5-1-1994

Kinematic analysis and synthesis of four-bar mechanisms for Kinematic analysis and synthesis of four-bar mechanisms for

straight line coupler curves straight line coupler curves

Arun K. Natesan

Follow this and additional works at: https://repository.rit.edu/theses

Recommended Citation Recommended Citation

Natesan, Arun K., "Kinematic analysis and synthesis of four-bar mechanisms for straight line coupler

curves" (1994). Thesis. Rochester Institute of Technology. Accessed from

This Thesis is brought to you for free and open access by the RIT Libraries. For more information, please contact

Acknowledgments

This

study

acknowledges

with

sincere

gratitude

and

thanks

the

patience

and

guidance

of

my

thesis

advisor,

Dr.

Nir

Berzak.

Without

his

extreme

accessibility

and

invaluable

advice,

this

thesis

would

never

have

gotten

its

shape.

Thanks

are

due

to

Dr.

Richard

Budynas,

my

program

advisor

for

his

support

throughout

my

M.S.

program.

Sincere

gratitude

is

extended

to

Dr.

Joseph

Torok

and

Dr.

Wayne

Walter

for

spending

their

valuable

time

in

reviewing

this

work.

Special

thanks

to

Ms.

Sandy

Grooms

of

Department

of

Engineering

Support

who

helped

me

in

getting

the

typed

version

of

this

report.

Last

but

not

least

deep

gratitude

is

expressed

to

my

mother,

my

brother,

my

sister

and

her

family

for

their

never-ending

patience

and

support.

ABSTRACT

Mechanisms

are

means

of

power

transmission

as

well

as

motion

transformers.

A

four-

bar

mechanism

consists

mainly

of

four

planar

links

connected

with

four

revolute

joints.

The

input

is

usually

given

as

rotary

motion

of

a

link

and

output

can

be

obtained

from

the

motion

of

another

link

or

a

coupler

point.

Straight

line

motion

from

a

four

bar

linkages

has

been

used

in

several

ways

as

in

a

dwell

mechanism

and

as

a

linkage

to

vehicle

suspension.

This

paper

studies

the

straight

line

motion

obtained

from

planar

four-bar

mechanisms

and

optimizes

the

design

to

produce

the

maximized

straight

line

portion

of

the

coupler-

point

curve.

The

equations

of

motion

for

four

different

four-bar

mechanisms

will

be

derived

and

dimensional

requirements

for

these

mechanisms

will

be

obtained

in

order

to

produce

the

straight

line

motion.

A

numerical

procedure

will

be

studied and

computer

codes

that

generate

the

coupler

curves

will

be

presented.

Following

the

numerical

results

study,

a

synthesis

procedure

will

be

given

to

help

a

designer

in

selecting

the

optimized

straight

line

motion

based

on

design

criteria.

CONTENTS

1

.

Introduction

1

2.

Mechanism

And

Its

Components

6

3.

Four-Bar

Mechanism

And

Its

Classifications

1

0

4.

Special

Four-Bar

Linkages

For

Approximate

Straight

Line

Output

1

9

5.

Position

Analysis

Of

A

Basic

Four-Bar

Mechanism

28

6.

Equation

Of

Coupler

Curve

For

A

Generic

Four-Bar

Linkage

35

7.

Four-Bar

Linkages

That

Generate

Symmetrical

Coupler

Curves

38

8.

Analysis

Of

Four-Bar

Linkages

Generating

Straight

Line

Coupler

Curves

47

9.

Numerical

Generation

of

Coupler

Point

Curves

58

10.

Synthesis

Procedure

For

Designing

A

Four

Bar

Linkage

68

1 1

.

Conclusion

73

12.

References

75

Appendix

A

Plots

Of

Straight

Line

Coupler

Point

Curves.

Appendix

B

Code

To

Generate

Coupler

Point

Curves.

1.

INTRODUCTION

One

of

the

main

objects

of

designing

a

mechanism

is

to

develop

a

system

that

transforms

motion

in

a

specific

way

to

provide

mechanical

advantage.

A

typical

problem

in

mechanism

design

is

coordinating

the

input

and

output

motions.

A

mechanism

designed

to

produce

a

specified

output

as

a

function

of

input

is

called

a

function

generator.

Such

a

function

generator

which

is

capable

of

producing

a

straight

line

output

has

found

a

wide

variety

of

applications.

A

system

that

transmits

forces

in

a

predetermined

manner

to

accomplish

specific

work

may

be

considered

a

machine.

A

mechanism

is

the

heart

of

a

machine.

It

is

a

device

that

transforms

one

motion,

for

example

the

rotation

of

a

driving

shaft,

into

another,

such

as

the

rotation

of

the

output

shaft

or

the

oscillation

of

a

rocker

arm.

A

mechanism

consists

of

a series

of

connected

moving

parts

which

provide

the

specific

motions

and

forces

to

do

the

work

for

which

the

machine

is

designed.

A

machine

is

usually

driven

by

a

motor

which

supplies

constant

speed

and

power.

It

is

the

mechanism

which

transforms

this

applied

motion

into

the

form

demanded

to

perform

the

required

task.

The

study

of

mechanisms

is

very

important.

With

the

tremendous

advantages

made

in

the

design

of

instruments,

automatic

controls,

and

automated

equipment,

the

study

of

mechanisms

takes

on

new

significance.

Once

a

need

for

a

machine

or

mechanism

with

given

characteristics

is

identified,

the

design

process

begins.

Detailed

analysis

of

displacements,

velocities

and

accelerations

is

usually

required.

Kinematics

is

the

study

of

motion.

The

study

of

motions

in

machines

may

be

considered

from

the

two

different

points

of

view

generally

identified

as

kinematic

analysis

and

kinematic

synthesis.

Kinematic

analysis

is

the

determination

of

motion

inherent

in

a

given

mechanism.

Kinematic

synthesis

is

the

reverse

problem:

it

is

the

determination

of

mechanisms

that

are

to

fulfill

certain

motion

specifications.

1.1

A

Brief

History

of

the

Development

of

the

Kinematics

of

Mechanisms

The

history

of

kinematics,

the

story

of

the

development

of

the

geometry

of

motion,

is

composed

of

evolvement

in

machines,

mechanisms

and

mathematics.

The

recent

investigation

of

mechanism

design

by

mathematicians

and

engineers

have

been

stimulated

in

part

by

the

increase

in

operating

speeds

of

machines

and

in

part

by

the

expectation

of

evolving

more

logical

approaches

to

the

development

of

mechanisms.

Franz

Reuleaux

was

the

first

scientist

who

systematically

analyzed

mechanisms,

deviced

machine

elements,

studied

their

combinations,

and

discovered

those

laws

of

operation

which

constituted

the

early

science

of

machine

kinematics.

His

now

classical

"Theoretische

Kinematik"

of

1875

presented

many

views

finding

general

acceptance

then

that

are

current

still

and

his

second

book,

"

Lehrbuch

der

Kinematic"

(1900),

consolidated and

extended

earlier

notions.

Reuleaux's

comprehensive

and

orderly

views

mark

a

high

point

in

the

development

of

kinematics.

He

devoted

most

of

his

work

to

the

analysis

of

machine

elements.

In

the

one

hundred

years

that

followed

Reuleaux,

the

contributions

of

such

scientists

as

W.

Hartmann,

H.

Alt,

F.

Wittenbauer

and

L

Burmester

developed

the

science

of

constructing

mechanisms

to

satisfy

specific

motions,

namely,

kinematic

synthesis.

The

techniques

they

used

were

based

on

mechanics

and

geometry.

It

was

not

until

1940

that

Svaboda

developed

numerical

methods

to

design

a

simple

but

versatile

mechanism

known

as

four-bar

linkage

(Fig.

1.1)

to

generate

a

desired

function

with

sufficient

accuracy

for

engineering

purposes.

The

input

crank

is

OaA

and

B

0>

O

B

ab

Frame

0AA

-

Rocker

AB

-

Coupler

0BB

-

Follower

Figure

1.1

A

Basic

Four-Bar

Mechanism

the

output

crank

is

OgB.

The

scale

to

input

crank

indicates

the

values

of

the

parameter

of

a

function,

and

that

on

the

output

crank

indicates

the

result

of

the

function.

Naturally,

this

four-bar

linkage

can

generate

only

a

limited

number

of

functions

because

of

the

nature

of

the

linkage

itself.

In

1951,

the

publication

by

Hrones

and

Nelson

of

an

"atlas"

containing

approximately

10,000

coupler

curves

offered

a

very

practical

approach

for

the

design

engineers.

The

Kinematics

of

mechanisms

has

gradually

become

a

popular

field

for

scholarly

and

engineering

investigation.

1.

2

Four-Bar

Mechanism

A

four-bar

linkage

is

a

versatile

mechanism

that

is

widely

used

in

machines

to

transmit

motion

or

to

provide

mechanical

advantage.

Four-bar

linkages

can

also

be

used

as

function

generators.

Their

low

friction,

higher

capacity

to

carry

load,

ease

of

manufacturing,

and

reliability

of

performance

in

spite

of

manufacturing

tolerances

make

them

preferable

over

other

mechanisms

in

certain

applications.

It

is

also

the

most

fundamental

linkage

mechanism,

and

many

more

complex

mechanisms

contain

the

four-bar

linkage

as

elements.

Therefore,

a

basic

understanding

of

its

characteristics

is

essential.

A

four-bar

mechanism

(Figure

1.2)

consists

of

four

rigid

members:

the

frame

or

fixed

member,

to

which

pivoted

the

crank

and

follower,

whose

intermediary

is

aptly

termed

coupler.

These

members

are

connected

by

four

revolute

pairs.

A

point

on

the

coupler

M

0

'////.

B

Figure

1.2

A

Four-Bar

Linkage

With

Coupler

Point

on

AB

is

called

the

coupler

point,

and

its

path

when

the

crank

is

rotated

is

known

as

a coupler

point

curve

or

coupler

curve

and

the

number

of

such

curves

are

infinite.

By

proper

choice

of

link

proportions

and

coupler

point

locations

useful

curves

may

be

found.

A

curve's

usefulness

depends

on

the

particular

shape

of

a

segment,

for

example,

an

approximate

straight

line

or

a

circular

arc,

or

on

a

peculiar

shape

of

either

the

whole

curve

or

parts

of

it.

The

coupler

point

because

of

its

motion

characteristic,

is

now

the

output

of

the

linkage.

Four-bar

mechanism

has

wide

range

of

applications

such

as

in

the

pantograph,

universal

drafting

machine,

Boehm's

coupling,

Poppet-valve

gear,

Whitworth

quick-

return

mechanism

and

Corliss

Valve-gear.

A

straight

line

output

from

a

four-bar

mechanism

has

been

used

in

several

ways

and

a

few

such

applications

are

linkage

for

vehicle

suspension,

linkage

for

posthole

borer,

in

textile

industries

and

in

material

handling

devices.

This

work

studies

mechanisms

and,

in

particular,

the

four-bar

mechanisms.

Four

popular

planar

four-bar

mechanisms

that

are

capable

of

generating

straight

line

motion

will

be

analyzed.

The

equation

of

the

coupler

curve

for

these

four-bar

mechanisms

will

be

derived

and

dimensional

requirements

for

these

mechanisms

will

be

obtained

in

order

to

produce

the

straight

line

motion.

Kinematic

analysis

will

not

be

complete

without

graphical

tools

for

the

designer

to

examine

the

output

of

the

mechanisms.

A

numerical

procedure

will

be

studied

and

computer

codes

that

generate

the

coupler

curves

will

be

presented.

Following

the

numerical results

study,

a

synthesis

procedure

will

be

given

to

help

the

designer

in

selecting

the

optimized

straight

line

motion

based

on

design

criteria.

2.

MECHANISM

AND

ITS

COMPONENTS

Configurations

of

mechanisms

have

been

incorporated

into

machines

for

centuries.

In

the

last

forty

years,

the

kinematics

of

mechanisms

has

emerged

as

an

engineering

science

and

consistent

terminology

and

definitions

were

necessitated

to

assist

research

and

communication.

A

mechanism

has

been

defined

by

Reuleux

as

a

combination

of

rigid

or

resistant

bodies

so

formed

and

connected

that

they

move

upon

each

other

with

definite

relative

motion.

It

is

the

device

that

transforms

one

motion,

for

example

the

rotation

of

a

driving

shaft,

into

another,

such

as

the

rotation

of

the

output

shaft

or

the

oscillation

of

a

rocker

arm.

A

linkage

or

linkwork

might

be

called

the

universal

mechanism,

since almost

any

conceivable

motion

can

be

produced

by

this

device.

A

linkage,

as

applied

to

mechanisms,

means

a

combination

of

a

number

of

pairs

of

elements,

such

as

levers,

cranks,

slides,

etc.,

connected

by

rigid

pieces

or

links,

all

the

parts

being

connected

by

pin

or

pivoted

joints

allowing

relative

motion

between

the

parts.

All

the

parts

must

be

so connected

that

when

any

one

part

is

moved,

definite

motion

is

imparted

to

all

the

other

parts.

A

few

terms

of

particular

interest

to

the

study

of

kinematics

and

dynamics

of

mechanisms

are

defined

below.

Link

A

link

is

one

of

the

rigid

bodies

or

members

joined

together.

The

term

rigid

link

or

sometimes

simply

link

is

an

idealization

used

in

the

study

of

mechanisms

that

does

not

consider

small

deflections

due

to

strains

in

machine

members.

A

perfectly

rigid

or

inextensible

link

can

exist

only

as

a

textbook

type

of

model

of

a

real

machine

member.

For

typical

machine

parts,

maximum

dimension

changes

are

of

the

order

of

only

a

one-

thousandth

of

the

part

length.

It

is

justified

to

neglect

this

small

motion

when

considering

the

much

greater

motion

characteristic

of

most

mechanisms.

The

word

link

is

used

in

a

general

sense

to

include

cams,

gears,

and

other

machine

members

in

addition

to

cranks,

connecting

rods,

and

other

pin-connected

components.

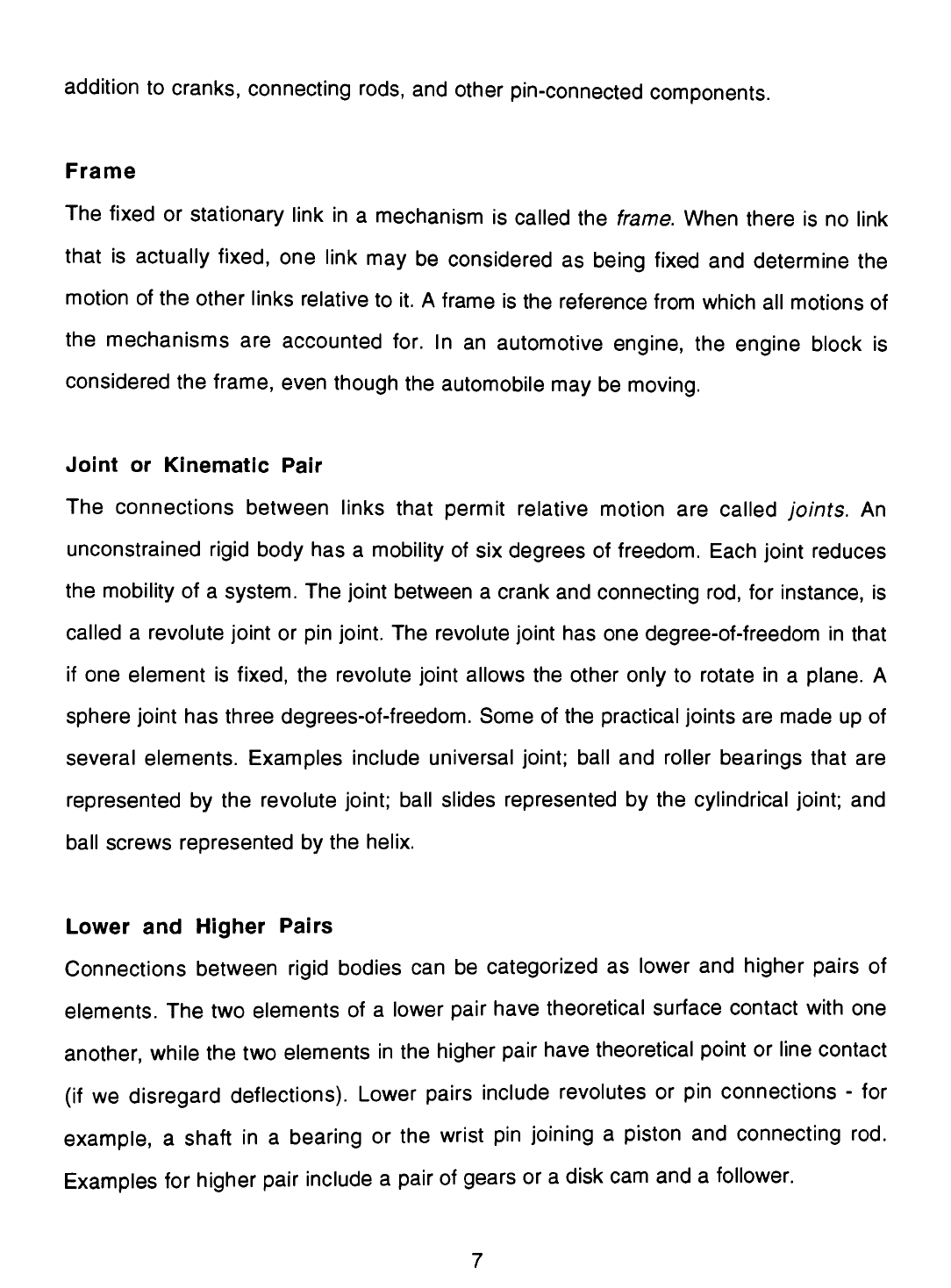

Frame

The

fixed

or

stationary

link

in

a

mechanism

is

called

the

frame.

When

there

is

no

link

that

is

actually

fixed,

one

link

may

be

considered

as

being

fixed

and

determine

the

motion

of

the

other

links

relative

to

it.

A

frame

is

the

reference

from

which

all

motions

of

the

mechanisms

are

accounted

for.

In

an

automotive

engine,

the

engine

block

is

considered

the

frame,

even

though

the

automobile

may

be

moving.

Joint

or

Kinematic

Pair

The

connections

between

links

that

permit

relative

motion

are

called

joints.

An

unconstrained

rigid

body

has

a

mobility

of

six

degrees

of

freedom.

Each

joint

reduces

the

mobility

of

a

system.

The

joint

between

a

crank

and

connecting

rod,

for

instance,

is

called

a

revolute

joint

or

pin

joint.

The

revolute

joint

has

one

degree-of-freedom

in

that

if

one

element

is

fixed,

the

revolute

joint

allows

the

other

only

to

rotate

in

a

plane.

A

sphere

joint

has

three

degrees-of-freedom.

Some

of

the

practical

joints

are

made

up

of

several

elements.

Examples

include

universal

joint;

ball

and

roller

bearings

that

are

represented

by

the

revolute

joint;

ball

slides

represented

by

the

cylindrical

joint;

and

ball

screws

represented

by

the

helix.

Lower

and

Higher

Pairs

Connections

between

rigid

bodies

can

be

categorized

as

lower

and

higher

pairs

of

elements.

The

two

elements

of

a

lower

pair

have

theoretical

surface

contact

with

one

another,

while

the

two

elements

in

the

higher

pair

have

theoretical

point

or

line

contact

(if

we

disregard

deflections).

Lower

pairs

include

revolutes

or

pin

connections

-

for

example,

a

shaft

in

a

bearing

or

the

wrist

pin

joining

a

piston

and

connecting

rod.

Examples

for

higher

pair

include

a

pair

of

gears

or

a

disk

cam

and

a

follower.

Kinematic Chain

A

kinematic

chain

is

an

assembly

of

links

and

joints.

In

a

closed

kinematic

chain,

e

link

is

connected

to

two

or

more

other

links.

Mechanism

A

mechanism

is

a

kinematic

chain

in

which

one

link

is

considered

fixed

for

the

purr.

of

analysis,

but

motion

is

possible

in

other

links.

As

noted

above,

the

link

design

as

the

fixed

link

need

not

actually

be

stationary

relative

to

the

surface

of

the

eart

kinematic

chain

is

usually

identified

as

a

mechanism

if

its

primary

purpose

is

modification

or

transmission

of

motion.

Linkage

If

kinematic

chains

are

needed

to

be

examined

without

regard

to

its

ultimate

use

assemblage

of

rigid

bodies

connected

by

kinematic

joints

of

lower

pairs

are

iden

as

a

linkage.

Thus,

both

mechanisms

and

machines

may

be

considered

link.

However

in

general,

the

term

linkage

is

restricted

to

kinematic

chains

made

lower

pairs.

Planar

Motion

and

Planar

Linkages

If

all

points

in

a

system

moves

in

parallel

planes,

then

that

system

undergoes

/

motion.

All

the

links

in

a

planar

linkage

have

planar

motion.

This

work

w

concerned

only

with

planar

linkages.

A

skeleton

diagram

of

a

planar

linkage

(e.c

Fig.

2.1)

is

formed

by

connecting

the

pin

centers

by

straight

lines

and

projecting

these

centerlines

on

one

of

the

planes

of

motion.

The

linkages

in

which

motion

(

be

described

as

taking

place

in

parallel

planes

are

called

spatial

or

three-dimer

(3D)

linkages.

8

Link

2

1

'////.

Link

3

3

'////.

Fig

2.1

A

Skeleton

Diagram

of

a

Planar

Linkage

Cycle

and

Period

A

cycle

represents

the

complete

sequence

of

positions

of

the

links

in

a

mechanism

(all

points

attained

between

two

identical

positions).

In

a

four-stroke-cycle

engine,

one

thermodynamic

cycle

corresponds

to

two

revolutions

or

cycles

of

the

crankshaft

but

one

revolution

of

the

camshaft

and,

thus,

one

cycle

of

motion

of

the

cam

followers

and

valves.

The

time

required

to

complete

a

cycle

of

motion

is

called

the

period.

3.

FOUR-BAR

MECHANISM

AND

ITS

CLASSIFICATIONS

An

important

property

of

a

classification

system

would

be

the

aid

it

could

furnish

a

designer

in

finding

the

forms

and

arrangements

best

suited

to

satisfying

certain

conditions.

The

planar

four-bar

mechanism

which

consists

of

four

pin-connected

rigid

links

gains

its

importance

as

a

basic

mechanism

because

it

is

one

of

the

simplest

of

all

mechanisms

to

produce.

The

four-bar

linkage

derives

its

renown

from

the

fact

that

the

members

of

a

three

bar

linkage

are

incapable

of

relative

motion

and

a

linkage

composed

of

more

than

four

bars

has

indeterminate

motion

with

a

single

input.

Though

it

may

assume

many

forms,

often

with

little

resemblance

to

the

usual

representation,

a

four-bar

linkage

consists

of

two

members

in

pure

rotation

about

fixed

axes,

called

the

driving

and

follower

crank;

a

coupler

in

combined

motion,

which

joins

the

moving

ends

of

the

cranks;

and

a

fixed

frame,

which

establishes

the

relative

position

of

the

stationary

crank

centers.

3.

1.

Classifications

and

the

Grashof

Criteria

There

are

two

main

classes

of

four

bar

mechanisms

based

on

the

rotational

and

dimensional

limitations

of

its

links

called

Grashof's

criterion,

which

are:

1.

Grashof

mechanisms,

which

is

comprised

of:

crank

rocker

mechanism

drag

link

mechanism

double

rocker

mechanism

crossover-position

or

change

point

mechanism

2.

Non-Grashof

Mechanisms,

which

includes

double

rocker

mechanisms

of

the

second

kind

or

triple

rocker

mechanisms.

10

A

Grashof

mechanism

is

a

four

bar

linkage

in

which

one

link

can

perform

a

complete

rotation

relative

to

the

other

three.

This

criterion

would

be

considered

if

we

plan

to

drive

a

linkage

with

a

continuously

rotating

motor.

It

will

be

shown

that

the

Grashof

criterion

is

met

if:

-max

+

Lmin

^

La

+

Lb

(3.1)

where

link

lengths

are

measured

between

bearing

centers,

Lmax

is

the

length

of

the

longest

link,

Lmjn

that

of

the

shortest

link,

La

and

Lb

are

the

lengths

of

the

remaining

links.

Fig.

3.1

Crank

Rocker

Mechanism

11

A

Grashof

mechanism

in

which

the

drive

crank

is

the

shortest

(and

Lmax

+

Lmjn

<

La

+

Lb)

will

act

as

a

crank

rocker

mechanism.

In

Figure

3.1,

the

skeleton

diagram

represents

a

crank

rocker

mechanism

where

link

0

represents

the

frame,

links

1

and

3

are

the

side

links

and

link

2

is

the

coupler.

The

smallest

side

link,

link

1,

often

acts

as

a

driving

crank.

The

rocker

link

(link

3)

will

oscillate

while

the

crank

(link

1)

is

rotated

continuously

in

one

direction.

Fig.

3.2

Drag

Link

Mechanism

12

A

Grashof

mechanism

in

which

the

fixed

link

is

the

shortest

(

and

Lmax

+

Lmjn

<

La

+

Lb)

will

act

as

a

drag

link

mechanism,

(see

Figure

3.2).

The

drive

crank

will

rotate

through

360

along

with

the

coupler

and

follower

crank.

A

Grashof

mechanism

in

which

coupler,

the

link

opposite

to

the

fixed

link,

is

shortest

and

Lmax

+

Lmjn

<

La

+

Lb

will

act

as

a

double

rocker

mechanism,

(see

Figure

3.3).

This

is

sometimes

called

double

rocker

of

the

first

kind.

Although

the

coupler

can

rotate

360,

neither crank

can

rotate

through

360.

In

a

linkage

of

this

type,

the

coupler

can

be

used

as

the

drive

member.

Figure

3.3

A

Double

Rocker

Mechanism

13

A

Grashof

mechanism

in

which

Lmax+

Lmjn

=

La

+

Lb

may

be

considered

a

crossover-position

or

change

point

mechanism.

Relative

motion

of

a

crossover

position

may

depend

on

inertia,

spring

forces,

or

other

forces

when

links

become

collinear.

Any

of

the

above

classes

of

linkages

may

be

driven

by

rotation

of

the

coupler

(the

link

opposite

the

fixed

link),

although

the

range

of

coupler

in

some

cases

may

be

very

limited.

The

coupler

effectively

provides

a

hinge

with

a

moving

center.

The

coupler-

driven

linkages

may

be

called

polycentric.

Four-bar

mechanisms

that

do

not

satisfy

the

Grashof

criterion,

Lmax

+

Lmjn

<

La

+

Lb

are

called

double

rocker

mechanisms

of

the

second

kind

or

triple

rocker

mechanisms.

In

this

case

no

link

can

rotate

through

360.

3.

2.

Proof

of

Grashof

Criteria

To

show

the

validity

of

the

Grashof

criteria,

we

may

begin

by

examining

a

crank

rocker

mechanism.

Referring

to

Figure

3.1

,

we

observe

that

the

range

of

motion

of

link

3

is

limited.

The

limiting

positions

of

link

3

occur

when

links

1

and

link

2

are

collinear.

The

linkage

arranges

itself

in

the

form

of

a

triangle.

Using

the

triangle

inequality,

we

obtain

the

required

relationships

between

lengths

of

the

crank

rocker

mechanism.

First,

using

Figure

3.4,

we

have

an

inequality

relating

the

length

of

the

fixed

link

to

the

others:

L0

<

L2

-

Li

+

L3

(3.2)

14

Figure

3.4

A

Limiting

Position

of

Crank

Rocker

Mechanism

Next,

a

similar

expression

is

obtained

for

follower

crank

3:

L3

<

L2

-

Li

+

Lq

(3.3)

Figure

3.5

Another

Limiting

Position

of

Crank

Rocker

Mechanism

15

From

Figure

3.5,

The

length

of

link

1

added

to

link

2

is

related

to

the

others

to

form

inequality:

Lt

+

L2

<

Lq+

L3

(3.4)

Combining

inequalities

3.2,

3.3

and

3.4,

we

have

L1+

IL2-L3I

<

L0

<

L<\

+

L3

(3.5)

Actually,

there

are

three

additional

possible

inequalities

based

on

the

triangle

formed

in

Figure

3.5,

but

these

three

inequalities

are

redundant.

Inequalities

3.2

and

3.3,

respectively,

may

be

written

in

the

following

form:

L-|

<

-

L0

+

L2

+

L3

(3.6)

1-1

<

L0

+

L2

"

L3

(3.7)

In

this

from,

the

inequalities

may

be

added

to

obtain

2

L-|

<

2

L2

or

L-j

<

L2

(3.8)

Similarly

using

inequality

3.2

and

3.4,

we

have

Li

<

L3

(3.9)

Using

3.3

with

3.4,

we

have

16

L1

<

L0

(3.10)

Thus,

if

the

driver

crank

(which

we

label

link

1)

is

the

shortest

link

in

a

four-bar

mechanism,

we

may

have

a

crank

rocker

mechanism.

If

inequalities

3.2,

3.3

and

3.4

are

satisfied

for

the

given

mechanism,

the

identification

of

the

mechanism

as

a

crank

rocker

mechanism

is

then

positive;

link

3

will

oscillate

as

link

1

rotates

continuously.

Substituting

Lmjn

for

L-|

and

Lmax

for

each

of

Lq, L2,

and

L3

in

turn,

in

inequality

3.5,

we

see

that

it

is

identical

to

the

more

concise

requirements

for

a

crank

rocker

mechanism:

(a)

Lmax

+

Lmjn

<

La

+

Lb

and

(b)

the

crank

is

the

shortest

link.

If

link

0,

the

fixed

link,

is

shortest,

as

in

the

drag

link

mechanism,

we

may

substitute

Lq

for

L-j,

L-|

for

L2

,

L2

for

L3

and

L3

for

Lq

in

inequality

3.2

to

obtain

L0

+

ll_-|

-L2I

<

L3

<

L-|

-

L0

+

L2

(3.11)

If

link

2,

the

coupler

link,

is

shortest,

as

in

a

double

rocker

mechanism,

by

similar

permutation,

we

obtain

L2

+

IL3-L0I

<

L-l

<

L3

-

L2

+

L0

(3.12)

Substituting

as

we

did

in

inequality

3.5

we

see

that

in

equalities

3.1

1

and

3.12

satisfy

the

Grashof

inequality:

Lmax

+

Lmin

<

La

+

Lb

(3-13)

Each

of

these

mechanisms

may

be

considered

as

inversion

of

the

others.

Four-bar

17

linkages

that

violate

the

Grashof

criteria

are

triple

rocker

mechanisms.

Each

Grashof

mechanism

has

two

assembly

configurations.

The

positions

attainable

in

one

assembly

configuration

are

not

attainable

in

the

other.

A

summary

of

the

results

is

given

in

Table

3.1.

Table

3.

1.

Summary

of

the

Criteria

of

Motion

for

Each

Class

of

Four-Bar

Linkages

l-min:

Lmax:

La

and

Lb:

shortest

link;

longest

link;

links

of

intermediate

links

Type

of

Mechanism

Shortest

Link

Relationship

Between

Links

GRASHOF

Any

-max

+

Lmin

-

La

+

Lb

Crank

rocker

Driver

crank

Lmax

+

Lmin

<

La

+

Md

Drag

link

Fixed

link

Lmax

+

Lmin

<

La

+

Lb

Double-rocker

Coupler

Lmax

+

Lmin

<

La

+

Lb

Crossover-position

Any

Lmax

+

Lmin

=

La

+

Lb

NON-GRASHOF

Triple-rocker

Any

Lmax

+

Lmin

>

La

+

Lb

18

4.

SPECIAL

FOUR-BAR

MECHANISMS

FOR

APPROXIMATE

STRAIGHT

LINE

OUTPUT

One

of

the

special

applications

of

four-bar

linkages

is

as

function

generators.

The

atlas,

Analysis

of

the

four-bar

linkage,

by

Hrones

and

Nelson,

contains

a

few

coupler

curves

with

approximate

straight

lines

that

have

been

useful

for

practical

design

problems.

Four

well-known

four-bar

linkages

which

are

capable

of

generating

straight

line

motion

will

be

introduced

in

this

chapter.

However,

those

mechanisms

given

by

the

atlas

are

inflexible

in

design,

and

only

occasionally

they

fit

the

problems

the

designers

face

in

practice;

in

most

cases

to

suit

particular

needs

mechanisms

for

straight

line

motions

needed

to

be

developed.

In

this

chapter,

these

four

mechanisms

will

be

categorically

defined

and

their

mobility

will

be

investigated.

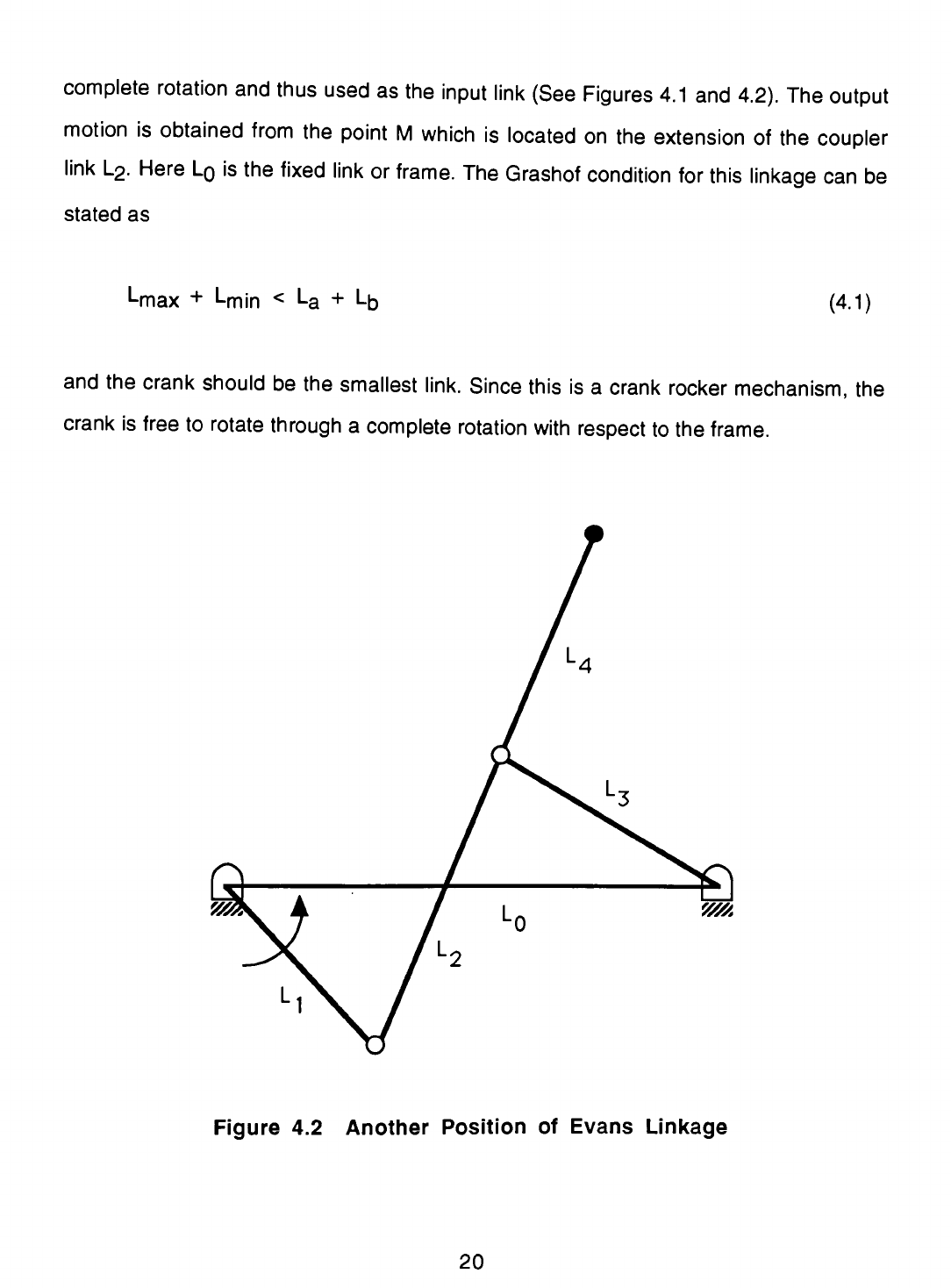

4.

1.

Evans

Linkage

Evans

Linkage

is

a

crank

rocker

mechanism

in

which

the

crank

L-|

rotates

through

a

Fig

4.1

Evans

Linkage

19

complete

rotation

and

thus

used

as

the

input

link

(See

Figures

4.1

and

4.2).

The

output

motion

is

obtained

from

the

point

M

which

is

located

on

the

extension

of

the

coupler

link

L2.

Here

L0

is

the

fixed

link

or

frame.

The

Grashof

condition

for

this

linkage

can

be

stated

as

Lmax

+

Lmjn

<

La

+

Lb

(4.1)

and

the

crank

should

be

the

smallest

link.

Since

this

is

a crank

rocker

mechanism,

the

crank

is

free

to

rotate

through

a

complete

rotation

with

respect

to

the

frame.

Figure

4.2

Another

Position

of

Evans

Linkage

20

4.

2.

Chebyshev

Linkage

Chebyshev

Linkage

is

a

four-bar

double

rocker

mechanism

where

the

coupler

rotates

through

360.

Figure

4.3

shows

a

schematic

diagram

of

the

Chebyshev

linkage.

In

Chebyshev's

Linkage

either

the

crank

or

the

coupler

can

be

used

as

the

input

link.

The

output

is

obtained

from

the

point

M

located

at

the

middle

of

the

coupler.

The

limiting

positions

of

the

crank

in

relation

to

the

frame

for

this

mechanism

are

shown

in

Figures

4.4

and

4.5.

Figure

4.3

Chebyshev

Linkage

The

conditions

for

Chebyshev's

Linkage

is

same

as

the

Grashof's

criteria:

Lmax

+

Lmin

<

La

+

Lb

(4.2)

and

the

smallest

link

is

the

coupler

L2.

The

limiting

angles

between

the

crank

and

the

frame

for

Chebyshev's

Linkage

are

calculated

using

cosine

law

(refer

Figure

4.4).

21

o

'////*

Figure

4.4

Limiting

Angle

of

Chebyshev

Linkage

By

cosine

law:

(L3

-

L2)2

=

|_02

+

Li

2

-

2

L0

L^

cos

0min

=>

Qmin

=

cos-1

{

[

L02

+

L^

-(L3-

L2)2

]/2

L0

L-\

}

(4.3)

Figure

4.5.

Another

Limiting

Angle

of

Chebyshev

Linkage

Similarly

to

calculate

0max

from

Figure

4.5,

22

=>

(L3

+

L2)2

=

L02

+

L-|2-2

Lq

L-|

cos

6max

6max

=

cos-1{[L02

+

L12-(L3

+

L2)2]/2L0L1}

(4.4)

4.

3.

Watts

Linkage

A

pictorial

representation

of

Watts

Linkage

(refer

Figure

4.6)

resembles

that

of

the

Chebyshev's.

But

it

differs

from

Chebyshev's

by

the

fact

that

it

is

not

a

double

rocker

mechanism

which

means

no

link

in

this

mechanism

rotates

through

360.

The

limiting

positions

of

the

crank

for

this

mechanism

are

shown

in

Figures

4.7

and

4.8.

Figure

4.6

Watts

Linkage

Being

a

non-Grashof

mechanism,

Watts

Linkage

does

not

satisfy

the

Grashof

Criteria.

The

condition

for

this

kind

of

link

mechanism

is,

Lmax

+

Lmin

>

La

+

Lb

(4.5)

23

Figure

4.7

Limiting

Position

of

Watts

Linkage

Figure

4.7

will

show

that

the

limiting

angle

emax

for

Watts

Linkage

can

be

calculated

as

same

way

as

that

of

Chebyshev's.

(I_3

+

L2)2

=

L02

+

Li

2

-

2

Lq

L<[

COS

6max

=>

emax

=

COS-1{[L02

+

L12-(L3

+

L2)2]/2LoL1}

(4.6)

and

in

this

case,

fynin

-

~

^max

(4.7)

Figure

4.8

The

Other

Limiting

Position

of

Watts

Linkage

24

4. 4.

Roberts

Linkage

Roberts

Linkage

is

a

mechanism

of

triple

rocker

kind

in

which

none

of

the

links

rotate

through

360.

Figure

4.9

shows

a

Roberts

mechanism.

Figure

4.9

Roberts

Linkage

From

the

limiting

positions

illustrated

by

Figure

4.10,

by

cosine

law,

L32

=

L02

+

(Lt

+

L2)2

-

2

L0

(Li

+

L2)

cos

emin

=>

emin

=

cos-1

{

[

L02

+

(Li

+

L2)2

-

L32

]

/

2

L0

(Li

+

L2)

}

(4.8)

25

Figure

4.11

The

Limiting

Positions

of

Roberts

Linkage

26

and

0max

is

calculated

as,

(L2

+

L3)2

=

Lq2

+

Li2

-

2

Lq

Li

cos

6max

=>

max

=

cos-1

{

[

Lq2

+

L^

-

(L2

+

L3)2

]

/

2

L0

Li

}

(4.9)

27

5.

POSITION

ANALYSIS

OF

A

BASIC

FOUR-BAR

MECHANISM

When

mechanisms

are

analyzed

both

graphical

and

analytical

methods

can

be

useful.

When

position

of

a

point

or

set

of

points

are

to

be

determined

for

a

single

linkage

position,

graphical

methods

are

usually

more

convenient.

Analytical

methods

are

more

practical

when

a

sequence

of

positions

of

a

mechanism

must

be

analyzed.

The

use

of

a

computer

permits

a

detailed

study

of

a

full

cycle

of

motion.

Once

the

initial

programming

is

completed,

little

effort

is

required

to

examine

the

effect

of

design

changes.

On

the

other

hand,

if

we

were

to

use

graphical

methods,

each

linkage

position

would

require

a

separate

plot

and

each

change

in

length

of

a

link

would

require

a

new

sequence

of

plots.

This

chapter

deals

with

the

analytical

method

of

determining

the

positions

of

the

links

relative

to

one

another.

Methods

of

vector

analysis

are

important

tools,

which

could

be

used

for

mechanism

analysis

and

synthesis.

5.1

Vectors

Vectors

provide

graphical

and

analytical

means

to

represent

motion.

A

quantity

described

by

its

magnitude

and

direction

can

be

considered

a

vector

and

can

be

graphically

represented

by

an

arrow.

The

length

of

the

arrow

is

proportional

to

the

magnitude

of

the

vector

quantity

and

the

direction

of

the

arrow

is

the

direction

of

the

vector

quantity.

Graphical

and

analytical

vector

methods

can

be

applied

to

linear

displacements,

velocities,

accelerations

and

forces,

and

to

torques

and

angular

velocities

and

accelerations.

Vectors

will

be

identified

in

this

study

by

boldface

type

to

distinguish

from

scalar

quantities.

28

In

general,

a

vector

of

unit

magnitude

can

be

called

a

unit

vector.

Thus,

A^

=

A

/

A

is

a

unit

vector

in

the

direction

of

A,

where

A

=

IAI

is

the

magnitude

of

vector

A.

A

coordinate

system

in

which

the

axes

are

mutually

perpendicular

is

called

a

rectangular

coordinate

system.

Unit

vectors

i,

j,

k

parallel

to

the

x, y,

z

coordinate

axes,

respectively,

are

particularly

useful,

since

we

are

going

to

use

only

rectangular

coordinate

system

throughout

this

work.

These

unit

vectors

are

also

called

rectangular

unit

vectors.

A

vector

may

be

described

in

terms

of

its

components

along

each

coordinate

axis.

When

we

use

vectors

to

describe

the

motion

of

a

linkage,

it

is

advisable

to

make

a

sketch

of

the

linkage

adjacent

to

vector

diagrams

so

that

vector

directions

can

be

referred

to

linkage

orientation.

5.

1.

1

Solution

Of

Planar

Vector

Equations

Consider

the

planar

vector

equation

A

+

B

+

C

=

0

or

in

terms

of

unit

vectors

(Au

etc.)

and

magnitudes

(A

etc.),

AU

A

+

BU

B

+

CU

C

=

0

If

the

magnitude

and

direction

of

the

same

vector

are

unknown,

then

the

solution

is

easily

obtained.

If

C

is

unknown,

we

use

C

=

-

(

Ax

+

Bx

)

i

-

(

Ay

+

By

)

j

or

C

=

-(Ai

+

B

i

)

i

-

(Aj

+

B

*

j

)

j

If

the

magnitudes

of

two

different

vectors

are

unknown,

a

vector

elimination

method

may

be

used.

Suppose,

for

example,

magnitudes

A

=

I

A

I

and

B

=

I

B

I

are

unknown

in

29

the

vector

equation

AU

A

+

BU

B

+

Cu

C

=

0.

We

take

the

dot

product

of

each

term

with

BU

x

k

noting

that

Bu

(

bu

x

k

)

=

0

since

vector

BU

is

perpendicular

to

vector

BU

X

k.

Thus,

we

obtain

AUA(BUXk)

+

C-(BUXk)

=

0

from

which

the

magnitude

of

vector

A

is

given

by

-C(BUXk)

A=

(5.1)

AU.(BUXk)

Similarly,

the

magnitude

of

B

is

given

by

-

C

(

AU

x

k

)

B

=

(

5.2

)

BU

(

AU

X k

)

If

the

vector

directions

Au

and

Bu

are

unknown

but

all

vector

magnitudes

are

known,

the

solution

to

the

equation

A

+

B

+

C

=

0

is

more

difficult.

The

results

in

this

case,

as

given

in

Reference

1

0,

are

A

=

_{B2

-[(c2

+

B2-A2)/2C]2}(1/2)

(CUXk)

+

{

[

(C2

+

B2

-

A2)/2C

]

-

C

}

CU

(5.3a)

or

A

=

+

{B2

-[(C2

+

B2-A2)/2C]2}(1/2)

(CU

X

k

)

+

{

[

(C2

+

B2

-

A2)/2C

]

-

C

}

CU

(5.3b)

and

B

=

+

{B2

-

[

(

C2

+

B2

-

A2

)/2C

]2

}(1/2)

(Cu

x

k

)

+

[

(C2

+

B2

-

A2)/2C

]

CU

(5.4a)

or

B

=

-{B2

-[(C2

+

b2-A2)/2C]2}(1/2)

(C"

X

k

)

+

[

(C2

+

B2

-

A2)/2C

]

CU

(5.4b)

30

When

the

magnitude

of

A

and

the

direction

of

B

are

unknown,

A

and

B

may

be

found

by

the

following

equations:

A

=

{

-

C

AU

V

B2

-

[

C

(

AU

X

k

)]2

}

AU

B

=

-

[

C

(

AU

X

k)

]

(

AU

x

k)

V

B2

-

[

C

(

AU

X

k

)]2

}

AU

(5.5)

(5-6)

The

above

approach

uses

vector

notation

throughout,

unlike

alternate

methods

that

use

vector

analysis

to

derive

scalar

equations.

When

the

above

method

is

used

for

computer-aided

analysis

and

design

of

mechanisms,

computer

subroutines

will

be

incorporated

to

handle

the

conversion

from

vector

to

scalars.

The

above

equation

will

be

applied

to

the

analysis

of

planar

linkages.

Figure

5.1

A

Basic

Four-Bar

Planar

Linkage

31

5.

2

The

Four

Bar

Linkage

A

graphical

layout

of

a

four

bar

linkage

can

be

easily

constructed.

We

only

require

to

know

the

position

of

one

link

be

given

in

relative

to

the

frame

and

the

link

lengths.

One

such

layout

for

the

simplest

four

bar

mechanism

is

given

in

Fig.

5.1.

Analytical

formulas

are

to

be developed

to

determine

all

the

link

positions

needed

to

write

a

computer

program.

The

following

analysis

provides

an

analytical

solution

for

a

simple

mechanism

shown

as

vector

notations

in

Fig.

5.2

and

this

can

be

modified

to

suit

the

different

kinds

of

four

bar

mechanisms

in

the

later

parts

of

this

chapter.

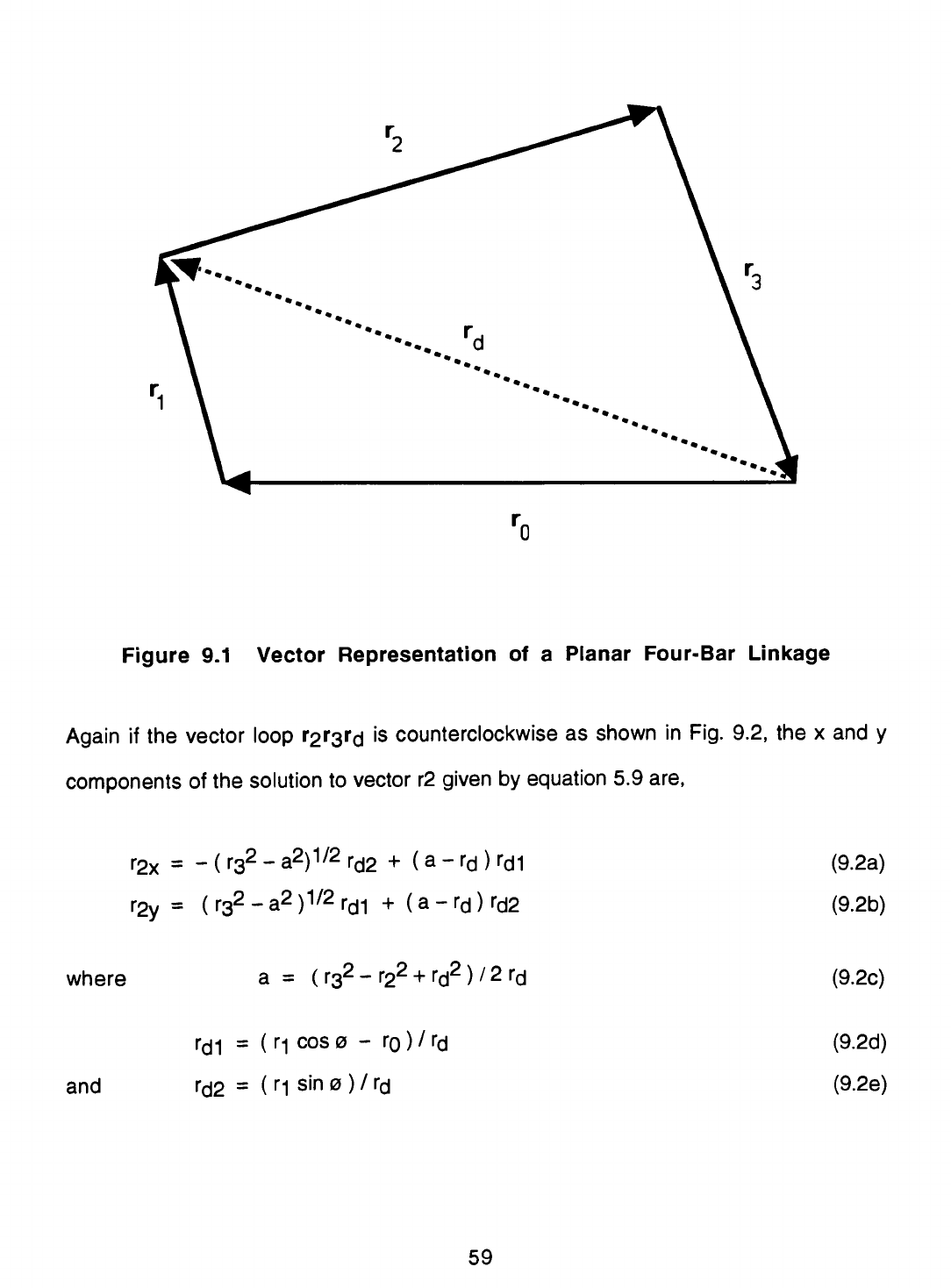

Note

that

there

are

two

different

modes

of

assembly

possible

for

a

non-Grashof

mechanism.

(Refer

Chapter

3).

Figure

5.2

Vector

Representation

of

a

Planar

Four-Bar

Linkage

32

5. 2.

1

Position

Analysis

Using

Vector

Cross

Product

Equations

5.3

and

5.4

may

be

used

to

find

linkage

displacements.

These

equations

apply

when

directions

of

vectors

A

and

B

are

unknown.

The

four

bar

planar

linkage

of

Fig.

5.2

is

described

by

the

vector

equation

r0

+

n

+

r2

+

r3

=

0

or

rd

=

-

(

r2

+

r3

)

where

the

diagonal

is

given

by

rd

=

r0

+

ri

If

the

lengths

of

the

links

are

specified

and

orientation

of

link

1

is

given,

then

the

following

substitution

may

be

made

in

equations

5.3

and

5.4:

A

=

r2

B

=

r3

C

=

rd=

r0

+

ri

yielding,

if

the

linkage

is

assembled

so

that

the

vector

loop

r2r3rd

is

clockwise

as

in

Fig.

5.2,

r2

=

-{r32

-

[(r32-r22

+

rd2)/(2rd)]2}1/2

(rduXk)

+

[(r32-r22

+

rd2)/(2rd)

-

rd

]

rdu

(5.7)

r3

=

+{r32

_

[(r32_r22

+

rd2)/(2rd)]2}1/2

(rduXk)

-

[(r32-r22

+

rd2)/(2rd)

-

rd

]

rdu

(5.8)

and

if

the

vector

loop

r2r3rd

is

counterclockwise

as

in

Fig.

5.3,

33

Figure

5.3

Vector

Representation

of

a

Four-Bar

Linkage

(Alternative

Mode

of

Assembly)

r2

=

+{r32

-

[(r32-r22

+

rd2)/(2rd)]2}1/2

(rduXk)

+

[(r32-r22

+

rd2)/(2rd)

-

rd

]

rdu

(5.9)

r3

=

-{r32

-

[(r32-r22

+

rd2)/(2rd)]2}1/2

(rduXk)

-

[(r32-r22

+

rd2)/(2rd)

-

rd

]

rdu

(5.10)

In

order

to be

used

in

a

computer

program,

analytical

formulas

are

to

be

developed

for

different

link

positions.

These

formulas

can

be

developed

using

the

concepts

of

vector

operations

and

incorporating

them.

34

6.

EQUATION

OF

COUPLER

CURVE

OF

A

GENERIC

FOUR

BAR

LINKAGE

In

order

to

investigate

algebraically

the

function

generated

by

a

coupler

point,

a

generic

equation

of

this

coupler

curve

should

be

obtained.

The

equation

of

the

coupler

point

curve

for

a

four-bar

linkage

was

first

derived

by

Samuel

Roberts

by

using

analytic

geometry.

The

equation

will

be

written

in

Cartesian

coordinates,

with

x

axis

along

the

line

of

centers

OaOb

and

the

y

axis

perpendicular

to

that

line

at

Oa

(See

Fig.

6.1).

Let

(x-|,yi),

(x2,y2),

and

(x,y)

be,

respectively,

the

coordinates

of

points

A,

B

and

coupler

point

M;

then

x-|

=

x

-

b

cos

9

yi

=

y

-

b

sin

e

and

x2

=

x-acos(e

+

y)

y2

=

y-asin

(6

+

y)

(6.1)

Since

A

and

B

describe

circles

(or

arcs

of

circles)

about

centers

Oa

and

Ob,

respectively,

Xl2

+

yi2

=

r2

and

(x2

-

p)2

+

y22

=

s2

(6.2)

Substituting

the

values

of

x-|,yi

and

x2,y2

into

the

last

two

equations

yields,

(x

-

b

cos

e)2

+

(y

-

b

sin

6)2

=

r2

and

[x-acos(e

+

y)-p]2

+

asin(e

+

y)]2

=

s2

(6.3)

which,

by

application

of

trigonometric

identities,

ordering

of

terms

and

simplification,

become:

35

B

Figure

6.1

A

Graphical

Layout

of

a

Generic

Four-Bar

Linkage

36

x

cos

0

+

y

sin

0

=

(x2

+

y2

+

b2

-

r2)

/

2

b

and

[

(x

-

p)

cos

y

+

y

sin

y

]

cos

0

-

[

(x

-

p)

sin

y

-

y

cos

y

]

sin

0

=

[(x-p)2

+

y2

+

a2-s2]/2a

(6.4)

The

equation

of

the

coupler-point

curve

may

now

be

obtained

by

elimination

of

0

between

the

last

two

equations.

Solving

these

equations

for

cos

0

and

sin

0

and

substituting

the

values

obtained

into

identity

cos2

0

+

sin2

0

=

1

yields

the

general

four-bar

coupler

curve

equation:

{

sin

a

[(x

-

p)

sin

y

-

y

cos

y

]

(x2

+

y2

+

b2

-

r2)

+

y

sin

p

[(x

-

p)2

+

y2

+

a2

-

s2]}2

+

{

sin

a

[(x

-

p)

cos

y

+

y

sin

y

]

(x2

+

y2

+

b2

-

r2)

-

x

sin

(3

[(x

-

p)2

+

y2

+

a2

-

s2]}2

=

4

k2

sin2

a

sin2

p

sin2

y

[x

(x

-

p)

-

y2

-

p

y

cot

y

]2

(6.5)

In

this,

k

is

the

constant

of

the

sine

law

applied

to

the

triangle

ABM,

a

b

c

sin

a

sin

p

sin

y

This

equation

is

of

the

sixth

degree

because

one

of

its

property

is

that

a

straight

line

will

intersect

it

in

no

more

than

six

points.

In

the

following

sections

the

equation

of

motion

of

specific

four-bar

mechanisms

will

be

derived

in

a

similar

approach.

37

7.

FOUR-BAR

MECHANISMS

THAT

GENERATE

SYMMETRICAL

COUPLER

CURVES

Symmetrical

curves

generated

by

a

four-bar

mechanism

have

received

a great

deal

of

attention

due

to

their

wide

applications.

In

this

chapter

conditions

for

a

four-bar

mechanism

to

produce

a

symmetrical

coupler

curve

will

be

discussed.

The

following

theorem

and

proof

were

presented

by

Berzak

(Reference

8

and

9).

Symmetrical

Coupler

Curves

Let

a

symmetrical

four-bar

mechanism

be