LED Retrofit Kits, TLEDs,

and Lighting Controls:

An Application Guide

Lighting use constitutes about 20%

of the total source electricity con-

sumption in commercial buildings.

The vast majority of lighting in U.S.

commercial buildings is provided by

fluorescent troer ceiling fixtures.

There are currently over 350 million

installed troers using more than 65

million kWh (the annual energy

usage of 6 million U.S. homes).

Retrofitting these fluorescent troers

to light-emitting diode (LED) sources

oers the potential for enormous

energy savings. As of 2015, only 5%

of the troers in use had LED light

sources. At a project level, retrofitting

or replacing fluorescent troers with

LEDs can result in energy savings of

20% to 60% and help agencies meet

energy-eciency goals.

Troer Lighting at a Glance

The term “troffer” is a combination of two different architectural elements: a “trough” and

a “coffer.” A troffer is a rectangular light xture designed to t into a modular dropped ceil-

ing grid. Fluorescent tubes were introduced to the market in 1938, and ceiling troffer x-

tures were soon designed to accommodate standard linear uorescent lamp sizes (T12s,

T8s, and T5s). Troffers are typically available in standard sizes of 1x4-ft, 2x4-ft, and 2x2-ft.

There are hundreds of millions of uorescent-based troffers in use in the United States;

nearly every commercial building has them. Around 2010, LEDs began to gain popularity

for interior lighting, and lighting manufacturers began designing troffer models with integral

LED sources. Most LED troffer luminaires sold today are still designed in the traditional

Have access to

ceiling plenum

and no known

hazards in ceiling?

Will you be in the

space more than

5 years?

yes

no/unknown

Consider a

retrofit kit

Do you want the

lowest first-cost

option?

no

yes

Consider

TLED

Do you want

lighting

controls?

yes

Consider Type C

TLED

Consider a

new fixture

yes

Consider Type A

TLED

no

Consider Type B

TLEDno

Are you looking for

FEMP designated

products?

yes

Is your space

covered by

GSA P100?

yes

yes

Is your space

covered by

DoD’s Unified

Facilities Criteria?

yes

yes

Will you plan for

ballast replacement in the future?

Does the facility understand the

potential shock hazard/risk of line

voltage being provided to the socket?

Are you willing to spend added

time and money to have the fixture

rewired by skilled electricians?

yes

yes

yes

yes

no

yes

no

yes

In a lighting upgrade of the New Carrollton Federal Building in Lanham, Maryland, the

General Services Administration cut energy use by 82% and trimmed an annual lighting

bill from $291,000 to $53,500 by replacing 11,800 fluorescent troers with LED fixtures

and controls. Photo source: GSA.

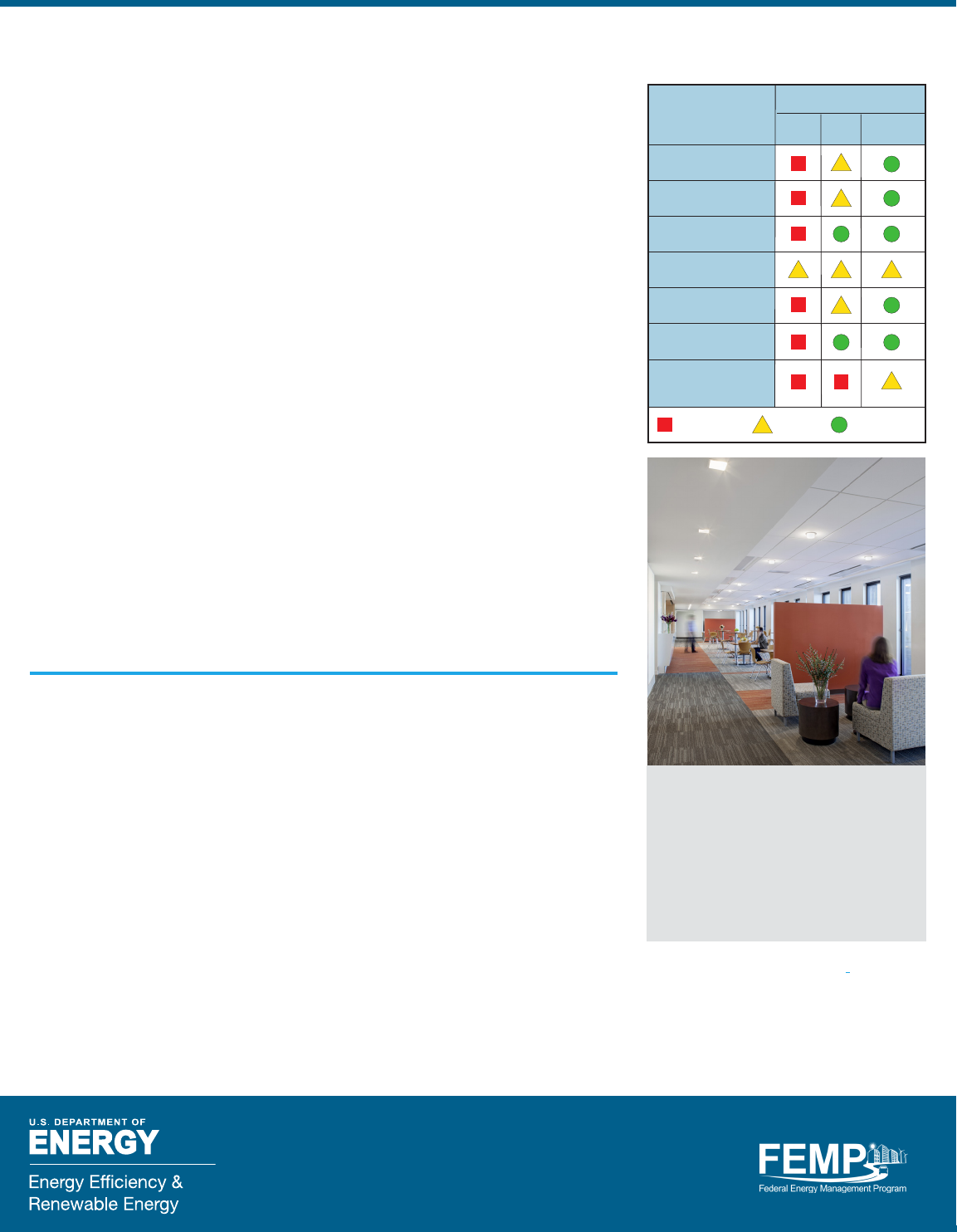

Figure 1. Determining the best LED troer retrofit option for your facility

LED Troer Retrofit Lighting and Controls

Best Practices

FEDERAL ENERGY MANAGEMENT PROGRAM

1x4-ft, 2x4-ft, and 2x2-ft rectangular troffer

shapes, although that may change for new

buildings as architects and lighting design-

ers realize they are free from the design con-

straints dictated by the size and shape of

linear uorescent troffers. Recognizing the

preponderance of uorescent troffers in

existing buildings, lighting manufacturers

also began to market tubular LED lamps

and LED retrot kits that replace the uo-

rescent light sources in existing troffers to

provide the same light levels with longer

lasting LED solutions that use less energy.

Retrofit Options

This document provides guidance for

retrotting existing uorescent troffer

xtures with LEDs. Information about

lighting controls is also provided.

There are three retrot options:

1. Lamp – Replace the lamp only with

tubular LEDs (TLEDs).

2. Retrot Kit – Replace the uorescent

lamps and other luminaire components

with an LED retrot kit.

3. Luminaire – Replace the entire uores-

cent luminaire, including the housing,

with a new LED luminaire.

Table 1 summarizes pros and cons of

each option, what agencies approve or have

criteria associated with an option’s use, and

an approximate sense of installation time,

energy savings, and rst cost.

Figure 1 (on the previous page) is a

decision tree to guide decision makers in

choosing the best option for their facility.

Reduced-

Wattage

Tubular

Fluorescents*

*This option is included for comparison purposes only.

Retrofit

Option

Installation

Time

First

Cost

Energy

Savings

Fed. Agency

Approved

(as of 2/1/2017)

Option

Pros Cons

Very low cost ($3–$10/lamp). Long life.

May use existing ballast so quick

installation.

Aging ballast may fail soon; may be hard

to find replacement. To add controls to

dim or reduce wattage, you must change

the ballast.

DoD: yes

GSA: yes

FEMP: yes

<5 min 20% ¢

TLEDs

In-Line

Ballast

TLEDs

Use existing ballast and sockets. No

rewiring, no electrician needed. Low

shock risk. Fast. Lowest cost on parts

and labor.

Aging ballast may fail soon; may be hard

to find ballast replacement in the future.

Possible ballast incompatibility. Possible

flicker. High risk of product failure. May

not dim. Least efficient of TLED options.

To add dimming controls, you must

change the ballast.

DoD: yes

GSA: case-by-case

FEMP: no criteria

<5 min 20% $

1

A

Line-Voltage

TLEDs

Does not rely on existing ballast. Greater

energy savings than in-line ballast. Low

cost on parts. Quick installation.

Potentially fatal shock hazard at

installation. Requires electrician.

Requires label. Heavy TLEDs might

cause issues with the lamp holders.

To add controls to dim or reduce wattage,

you must change the ballast.

DoD: no

GSA: case-by-case

FEMP: no criteria

<15 min 30%–50% $$

B

External-

Driver TLEDs

Safer than Type B. External driver

provides better thermal management.

Easier to add controls.

Lower voltage from driver to sockets.

Lower cost than retrofit kits. Most

efficient of the TLED options.

Requires electrician. Requires a label.

Not as efficient as retrofit kits. Heavy

TLEDs might cause issues with the

lamp holders.

DoD: no

GSA: case-by-case

FEMP: no criteria

<15 min 30%–50% $$

C

Retrofit Kits

Uses existing housing but replaces old

lamps, ballasts, and sockets with new

electronics and LED modules for longer

life. Better heat management and lower

failure potential than TLEDs. Higher

efficiency than TLEDs. Can add lighting

controls. Less labor than a new fixture.

Higher parts and labor costs than TLEDs.

Requires electrician.

DoD: yes

GSA: yes

FEMP: no criteria

<15 min 60% $$

2

New

Luminaires

Maximum energy savings. Fixture is

designed to optimize LED source

performance. Maximum potential for

adding lighting controls. Could add

non-lighting controls (carbon dioxide,

heat, etc.) Lowest failure potential;

longest lasting.

Most expensive for parts and labor.

Requires electrician. May require access

above ceiling; potential safety and health

risks. Most time to install. One-for-one

replacement may over-light space and

may require costly redesign for maximum

efficiency.

DoD: yes

GSA: yes

FEMP: yes

>30 min 60% $$$

3

Table 1. Comparison of LED Options for Retrofitting Troers: Pros and Cons, Costs and Benefits

FEDERAL ENERGY MANAGEMENT PROGRAM

2

Tubular LEDs

Tubular LEDs (TLEDs) are LEDs that

match the form factor (diameter, length,

and base) of uorescent tubes so they can

plug into the existing sockets in a uores-

cent troffer. There are three types of

TLEDs:

1. Underwriters Laboratory (UL)

Type A – The TLED uses the

existing uorescent ballast; the

TLED also has an internal driver.

2. UL Type B – The wiring from the

existing ballast is terminated, the sock-

ets are rewired from the branch circuit,

and the TLED operates from line volt-

age supplied directly to the xture; the

TLED has an internal driver.

3. UL Type C – The TLED uses line volt-

age, but electrical connections to the

ballast are terminated and the line volt-

age is connected to an external driver

that powers the TLED.

When considering retrot options, TLEDs

tend to be the least expensive rst-cost

option. Another big advantage of TLEDs

is the time savings. In many cases, the

reectors and louvers or lens remain; the

only part being replaced is the lamp (how-

ever, sometimes the sockets also need to

be replaced). Installing a UL Type A

TLED is as easy as replacing a uorescent

lamp. UL Type B and Type C lamp

replacements take slightly longer because

they require some rewiring, which can

also increase the labor costs as an electri-

cian is required. Figure 2 depicts these

three TLED types, and Table 1 lists pros

and cons of each.

With UL Type A TLEDs, the existing bal-

last stays connected to the sockets,

whereas with Type B and C TLEDs, the

ballast is disconnected. While uorescent

lamps use a ballast to regulate current and

provide voltage to start the lamp, LEDs

use a driver instead; the driver controls the

current and regulates the power. While UL

Type A and Type B TLEDs have an inter-

nal driver, UL Type C TLEDs have an

external driver, which provides better

thermal management and may contribute

to a longer lasting lamp.

Although UL Type A TLEDs may seem

like the simplest retrot option because

you can reuse the ballast, there are sev-

eral things to keep in mind about uores-

cent ballasts and TLEDs:

• The uorescent ballast will limit the

energy efciency of the luminaire. UL

Type A TLEDs are the least

efcient of the TLEDs.

• Ballasts vary and it cannot be assumed

that all ballasts will work with all

TLEDs. Fixture manufacturers supply

different ballasts in the same xture

line to reduce supply chain risks, so

two otherwise identical xtures could

have different ballasts, which could

lead to compatibility issues with some

xtures in a project.

• Aging ballasts are likely to fail before

the TLED fails. As LEDs gain market

share, some ballasts may become

harder to nd. If your ballasts are

older than 5 years, consider UL Type

B or C replacement lamps, retrot kits,

or new luminaires instead.

• As uorescent ballasts age, they may

cause icker in some UL Type A

TLEDs.

• Emer gency lighting might be incom-

patible with some UL Type A TLEDs,

so test the TLEDs if using them in an

emergency lighting system.

UL Type B TLEDs, also sometimes

referred to as line-voltage TLEDs, have the

highest safety risk because they involve

rewiring 120-volt line voltage directly to

the sockets. The installer is required to put

a label on the xture indicating that the x-

ture has been modied, that a potential

shocking hazard exists, and that the lamp

should not be replaced with a uorescent

lamp. Because of the high voltage, the

shock could cause serious injury or death.

The Federal Energy Management Program

(FEMP) has no stated minimum efcacy

requirement for TLEDs, but it does have a

FEMP-designated minimum requirement

for linear uorescent lamps of 98 lumens

per watt (lm/W). (This is measured as bare

lamp, or with the lamp outside of the x-

ture.) So, when considering replacing uo-

rescents with TLEDs, to achieve energy

savings, the TLED should at a minimum

have an efcacy greater than 98 lm/W. The

U.S. Department of Defense’s Unied

Facilities Criteria (DoD UFC) requires that

TLEDs have a minimum efcacy of 100

lm/W (bare lamp). The Design-Lights

Consortium requires that TLEDs have a

minimum efcacy of 110 lm/W, which is a

good rule of thumb to achieve at least 10%

energy savings over the minimum require-

ment for uorescent tubes.

UFC does not have a light output require-

ment for TLEDs, but the DesignLights

Consortium’s requirement of 1,600 lumens

(bare lamp) is a good minimum for TLED

lamp retrots.

TLED UL Type A TLED UL Type B TLED UL Type C

From Branch Circuit (line voltage, 120 or 277 volts)

Internal

Driver

External

Driver

Socket

Existing

Ballast

Lower

Voltage

LEDs

Figure 2. TLEDs can fit into existing sockets. UL Type A TLEDs use the existing driver. UL

Type A and B TLEDs have internal drivers while Type C TLEDs have external drivers.

FEDERAL ENERGY MANAGEMENT PROGRAM

3

Retrofit Kits

Retrot kits cost more than TLEDs but are

generally more efcient and, in some

cases, can be installed almost as quickly as

UL Type B or C Type C TLEDs. Figure 3

shows the components in a uo rescent trof-

fer and the same troffer housing with an

LED retrot kit.

The industry uses the term retrot kit,

while some federal agencies use the term

conversion kit. UFC denes a luminaire

conversion kit as a sys tem that replaces the

lamp and other lumi naire components,

including the ballast and/or the reector,

wiring, and diffusers. According to UFC,

direct replacement of a uores cent or other

lamp with an LED lamp without electri cal

or mechanical changes is not considered to

be a luminaire conversion.

Installation Time Requirements

Although the electrical components (bal-

lasts, sockets, and wiring) of the troffer are

disconnected and, in most cases, removed

with retrot kits, retrot kits allow for the

xture housing to remain in place. Not

having to disconnect the housing from the

ceiling to install a new housing is a signi-

cant time-saving feature of retrot kits. The

space above a xture might have hazard-

ous materials that could require remedia-

tion. As labor costs can easily exceed the

cost of materials, any reduction in labor

time will add to the cost effectiveness of

the upgrade. Some troffer xture designs

Federal LED Troer Lighting Requirements

TheUSDepartmentofEnergy’sFederalEnergyManagementProgram(FEMP)provides

informationaboutenergyecientproductsandpromisingnewenergy-savingtechnolo-

giesthatcanhelpagenciesmeetfederalstandardsFederallawsandrequirementsman-

datethatagenciespurchaseENERGYSTAR-labeledorFEMP-designatedproductsinall

productcategoriescoveredbytheseprogramsENERGYSTARdoesnotcovercommercial

lightingproductsliketroersFEMP-designatedeciencyrequirementscovercertaincom-

mercialandindustriallight-emittingdiode(LED)luminaireproductcategories(seeTable)

TherearenoFEMP-designatedrequirementsfortubularLEDs(TLEDs)andLEDretrofitkits

ForbranchesofthemilitarytheUSDepartmentofDefense(DoD)hassomeadditional

requirementswhichareoutlinedintheUnifiedFacilitiesCriteria(UFC)TheUSGeneral

ServicesAdministration(GSA)establishesdesignstandardsfornewbuildingsandretrofits

initsguideFacilities Standards for the Public Buildings ServicereferredtoasP(See

the“Resources”sectionofthisguideforlinksandadditionalinformation)Tableshowsthe

Federalagencyrequirementsalongwithsomevoluntaryfederalprogramcriteriafornew

andretrofittroeroptions

are more difcult to retrot because the

xture housing is contoured around the

lamps. (See Table 4.) Also, the light distri-

bution may differ after retrot because the

optics are designed for uorescent lamps.

Ecacy

Neither FEMP nor the U.S. General

Services Administration (GSA) have

requirements for retrot kits. UFC requires

that retrot kits be 120 lm/W. For compari-

son, FEMP does have a minimum efcacy

requirement for new LED troffer lumi-

naires of 99 to 103 lm/W, depending on the

conguration, which is quite a bit higher

than its minimum requirement for new u-

orescent luminaires of 55 to 89 lm/W. (See

Table 2 for more on requirements.) UFC

does not have a minimum light output

requirement, but states that “the resulting

system must produce equivalent light lev-

els.” UFC also requires that the kit produce

at least 70% of the initial light for at least

50,000 hours.

FEMP Designated

DoD Unified Facilities

Criteria - UFC 3-530

(June 2016)*

GSA P100 (March 2016)**

Voluntary

DesignLights Consortium

(Version 4.1)

Better Buildings Alliance

Model Technical Specification

for High Efficiency Troffers

(Version 6.0)

NR

100 lm/W

(bare

lamp)

NR

110 lm/W

(bare

lamp)

NA

NR

120

lm/W

NR

100

lm/W

NA

≥99 lm/W (1x4)

≥100 lm/W (2x2)

≥103 lm/W (2x4)

NR

NR

100 lm/W

125 lm/W

≥1,500 lm (1x4)

≥2,000 lm (2x2)

≥3,000 lm (2x4)

Retrofit Kit:

Equivalent light

level; ≥70% of

initial light for

≥50,000 hours

NR

1,500 lm (kit/

luminaire)

1,600 lm (bare lamp)

1,500 lm (1x4)

2,000 lm (2x2)

3,000 lm (2x4)

NR

≤4100 K

≤3500 K

≤5000 K

2200K-

5000K

NR

≤80

≤80

≤80

≤80

Device Efficacy (lumens/Watt)

TLED Retrofit

Kit

New/Replacement

Luminaire

Light Output

(lumens)

Color Characteristics

CCT CRI

CCT = Correlated color temperature; CRI = Color rendering index; K = Kelvin; NA = Not applicable; NR = No requirement

*As of June 2016, DoD UFC allows Type A TLEDs for all military branches.

**TLEDs UL Type A, B, and C are only approved by GSA on a case-by-case basis.

Federal Standard

Table 2. LED Requirements in Federal Programs

Lamp

Ballast

Reflector

Housing

Ceiling

Tile

Lens

LEDs

External Driver

Reflector

Housing

Ceiling

Tile

Lens

Figure 3. Troer Retrofit – before and

after installing the retrofit kit

Fluorescent Troer

LED Troer Retrofit Kit

FEDERAL ENERGY MANAGEMENT PROGRAM

4

Controls

Retrot kits offer greater energy savings

potential from lighting controls than is

possible with TLEDs. The retrot kit

body itself provides a physical location to

mount the sensors to. For small retrots,

retrot kits can interface with stand-alone

wireless controls systems. For large-scale

whole-building retrots, more complex

controls systems can be deployed while

new retrot kit wiring is being installed.

New Luminaires

Replacing the entire xture with new x-

tures is typically the most expensive

option. However, it offers several

advantages. It is likely to provide both the

highest efciency and effectiveness, in

terms of the light source itself and

because the xture components and hous-

ing shape are designed to maximize light

output from an LED light source.

Depending on the model, it is likely to

work most seamlessly with controls and

may come with the controls integrated in

the xture by the manufacturer. It is likely

to be a longer lasting option. If the exist-

ing equipment is in poor condition, total

xture replacement may be the only

option. The biggest disadvantage is the

need to remove the housing from the ceil-

ing, which may require access above the

ceiling and potential health and safety

risks, as well as increased product and

labor costs.

Factors to Consider

Selecting the best option for an installa-

tion depends on several factors: the cur-

rent condition of the ballast and luminaire

components, desired photometric proper-

ties of the upgraded lighting system,

accessibility of the ceiling plenum, pur-

chase and installation budget, and ongo-

ing economic goals for the upgrade.

Product quality and performance vary

widely within each upgrade option and

individual products should be evaluated

on their own merits. Here is some guid-

ance on the various factors to consider

when deciding among the options for an

upgrade to LED troffer lighting.

Existing Condition of

Luminaires

Consider the condition of the luminaire

when deciding whether to relamp, retrot,

or replace. Damaged housings, cracked or

discolored lenses, scratches, yellowing of

the reector, peeling paint, and rusted or

broken components can all contribute to

the decision to replace or retrot the lumi-

naire rather than just replacing the lamps.

If the ballast is older than 5 years, a UL

Type A TLED lamp-only replacement is

not recommended. Luminaire design can

also make replacing the lamps challeng-

ing (see Table 4).

Equipment Purchase Costs

When considering purchase price, LED

replacement lamps are usually the lowest

cost option, retrot kits are higher, and

new LED luminaires are the highest cost.

Compare purchase and installation prices

when considering retrot kits versus new

luminaires; retrot kits are not always a

bargain.

Installation Labor Costs

TLED replacement lamps that simply

snap into the existing uorescent lamp

sockets can be installed in minutes per

lamp, providing the lowest labor installa-

tion costs. However, some products mar-

keted as replacement lamps require

modications to the luminaire and will

have labor costs similar to products mar-

keted as retrot kits. (For example, UL

Type A TLED lamps do not require

wiring modications, but Type B and C

TLEDs do.)

Labor costs for installing retrot kits are

generally higher than those for installing

replacement lamps but should be less than

those for installing new LED luminaires.

Some older systems have ballasts that

contain PCBs, a hazardous substance that

requires proper handling and disposal,

which can add to the installation costs.

Ceiling Plenum Access

If you are considering replacement

luminaires, determine if access above

the ceiling will be required for

installation, if the space is accessible, and

if above-the-ceiling work might release

contaminants into the occupied space.

Some older buildings may contain asbes-

tos in or above the ceiling tiles that could

become harmful if disturbed. When work-

ing in health care environments, addi-

tional protocols may apply (for example,

if the trof fer replacement work could

introduce dust into the space), and these

protocols could add time and cost to the

project.

Energy Savings

Generally, one would expect new LED

luminaires to provide the greatest energy

savings, followed by retrot kits, then

replacement TLEDs. In some cases, the

retrot products advertised as offering the

greatest wattage reduction also deliver

much less light than the existing system.

Compare efcacy ratings to ensure you

are getting the amount of light you want;

efcacy is the amount of lumens produced

per watt of power drawn.

Controls can greatly add to project

savings. New luminaires may allow for

more controls options and can be

purchased with integrated controls; see

the “Lighting Controls” section of this

guide for more information.

Light Levels

For light output equal to what you cur-

rently have, measure your current lighting

using a light meter, compare luminaire

efcacy ratings, or use the estimates under

“light output” in the box “How LEDs

Measure Up” on the next page. If the cur-

rent space is over-lighted, the greatest

savings may result from installing lower

light output luminaires or recon guring

the layout to use fewer lumi naires.

The light distribution also needs to be

evaluated. LEDs have different distribu-

tion characteristics that can increase the

chances of glare from the luminaire, cause

uneven light levels in task areas, and

reduce light on the walls. Detailed calcu-

lations or measurements of a mock-up

installation can help you assess the light

levels beneath and between the luminaires.

FEDERAL ENERGY MANAGEMENT PROGRAM

5

is expressed in Kelvins (K). The CCT val-

ues of most commercially available light

sources range from about 2700 K to 6500

K, with warmer, yellow-white light at the

lower end (incandescent light is typically

about 2700 K), and cooler blue-white light

at the higher end. U.S. residents prefer

lighting in the range of 2700 K to 4000 K.

Some LED xtures allow for “color tun-

ing,” which means the CCT can modulate

from about 2700 K to 6500 K. Claims

have been made about the potential for

color tuning to improve worker productiv-

ity, but research on this is still being

conducted.

Color rendering index (CRI) indicates how

well the light source renders the colors of

an object compared to a reference light

source, on a scale from 0 to 100, where the

higher numbers correspond to superior

Color Quality

In addition to the light output of the troffer,

the color characteristics of the light from

the troffer play a critical role in the accept-

ability of the technology. Color quality can

affect the work being done in lab and man-

ufacturing facilities and is an important

aspect of diagnoses in health care settings.

Correlated color temperature (CCT) is the

color appearance of the light generated and

How LEDs Measure Up

There are several measurements for describing lighting.

Ecacy is one key metric for comparing the energy eciency of lighting equipment. Lighting ecacy is the conversion of power (Watts)

into light (lumens) and is expressed as lumens per Watt (lm/W). Federal agencies and industry use several terms for ecacy; these are all

basically synonymous as long as the unit is lm/W: luminaire ecacy (LE), luminaire eciency, luminaire ecacy rating (LER), luminous

ecacy, or ecacy. There are three key points to remember about lighting ecacy: (1) The higher the number of lumens, the greater the

energy eciency. (2) Ecacy does not measure eectiveness. You should test the light distribution with an actual installation in the space

if possible before doing a building-wide retrofit. (3) Pay attention to whether the ecacy rating is for the bare lamp (or retrofit kit alone)

or the whole fixture. When a tubular light-emitting diode (TLED) or kit goes into a fixture, the ecacy for the fixture will be lower than the

bare lamp/kit ecacy because the fixture traps some of the light.

If you know the ecacy of the TLED, you can determine the ecacy of the whole luminaire fairly easily using this rule of thumb. Troer

fixtures absorb roughly 25%–35% of the light generated by the fluorescent lamps, i.e., one-quarter of the light produced by the lamps

never leaves the fixture. This 25% value can be used as a proxy to determine the LER for LEDs. If a Unified Facilities Criteria (UFC)-

compliant (100 lm/W) TLED were installed in a troer that absorbs 25% of the light, then the fixture would have an LER of roughly 75

lm/W (75% x 100 lm/W).

Illuminance is the amount of light falling on a surface and is measured in foot-candles which is lumens/square foot. UFC 3-530 provides

guidance based on the space being lighted. U.S. General Services Administration (GSA) P100 references the Illuminating Engineering

Society of North America (IES) Lighting Handbook for recommendations on illuminance levels.

When determining illuminance levels for a space, consider the age of the occupants and what type of work will be done in the space.

Older eyes and highly detailed work may both require higher illuminance levels from the troer lighting, or perhaps the addition of task

lighting.

Brightness is a perception. It is related to the amount of light emitted by the fixture, but two troers can emit the same amount of lumens

and one can appear brighter than the other. The reasons for dierences in perceptions of brightness include distribution, optical design,

and possibly glare. Evaluate luminaires before installation to prevent complaints that the lighting may be too bright. Fixes to reduce

brightness can also reduce illuminance, which could result in complaints that the lighting level is too low.

Light output is the amount of light emitted by a device and is measured in lumens. See Table 2 for federal requirements for LED troer

light output. When upgrading lighting from fluorescent to LED using retrofit kits or luminaire replacements, if you wish to maintain the

current lighting levels, you can use the

light outputs listed in Table 3 as an

estimation of what your current light

levels are, based on your current

fluorescent troer configuration.

When considering replacing an

existing fluorescent lamp with a

TLED, assume that each fluorescent

lamp has an output of 2,500 lumens.

Troffer Configuration 1 Lamp 2 Lamps 3 Lamps 4 Lamps

1’ X 4’ 1,000–1,500 3,000–4,000 4,500–6,000 NA

2’ X 2’ NA 2,500–3,500 NA NA

2’ X 4’ NA 2,500–4,000 4,000–5,000 6,000–7,500

NA = No applicable lamp models exist. Light output listed in lumens.

Table 3. Typical Fluorescent Light Output

FEDERAL ENERGY MANAGEMENT PROGRAM

6

color rendering. However, research has

indicated that this metric does not pro-

vide the best comparison of light

sources, and the lighting industry is

moving beyond this metric to include

more elements of color. Until new met-

rics gain market traction, both the GSA

and UFC documents require a CRI of at

least 80.

Flicker

Flicker is the constant uctuation of light

output from 0% to 100%. Virtually all

humans perceive icker when the fre-

quency is 50 hertz (Hz) or lower; some

can perceive it between 50 and 100 Hz.

Factors that could introduce icker in an

LED include the electrical supply, the

LED driver, a dimming system, and,

when using TLEDs, possibly the exist-

ing uorescent ballast. The industry is

working on a suitable metric for icker.

At this time, the best method for deter-

mining whether icker is occurring and

whether it is acceptable is to install the

product and observe it.

Description

Prismatic Lensed – This was the original

troffer design. It utilizes a flat lens and is

required in clean rooms, food processing

areas, and some healthcare applications.

Parabolic Louvers – The vast majority of

troffers in offices are parabolic louvers. The

louvers act to reduce glare from fluorescent

lamps. When TLEDs are installed, there

might be more glare because of differences

between the light distribution of the TLEDs

and fluorescent lamps.

Recessed Indirect – These are “softer” in

appearance. The perforated metal reduces

light output and addresses glare. However,

these fixtures are very inefficient. More than

50% of the light generated by the fluores-

cent lamp can be absorbed by the perforat-

ed metal.

Volumetric – These are lensed troffers

where the lenses contour around the

fluorescent lamps. The term volumetric was

coined because these troffers light high on

the wall, making the space feel brighter

while managing potential glare.

High Performance – These are next-

generation volumetric troffers. The optical

system has been maximized for light output

while the distribution has been optimized

to properly light the space.

Troffer Image Troffer Cross Section View TLED Kit

Retrofit

= few limitations

= proceed with

caution

= lamp

= housing

= ballast

= reflector

= louvers

= lens

Color key to components:

Table 4. Types of Troers and Retrofit Options

FEDERAL ENERGY MANAGEMENT PROGRAM

7

retrot project, savings can be expected to

increase 32% on average.

Multiple sensor strategies should be

considered. Although multiple strategies

may yield greater sav ings than any one

strategy alone, energy savings are not

additive.

Dimming controls reduce the light out-

put and energy consumption as controlled

by the occupant, by timers, or by daylight

sensors. Not all LED products are dimma-

ble. Evaluate product samples throughout

the dimming range for possible icker.

Task tuning is the reduction of light out-

put via dimming to suit occupant needs.

Tuning at the institution level can typi-

cally save 8% energy, and tuning at the

individual level can save about 7% on

average. However, the energy savings are

less consistent than for other strategies

because they depend on nishes in the

space, the lighting system installed, and

the occupant’s preference. Depending on

how the lighting system is designed

initially, tuning may be not needed or

not achievable.

Federal Resources

All federal agencies must comply with FEMP

requirements. In addition, some federal agen-

cies, such as DoD and GSA, have their own

lighting requirements documents. The U.S.

Department of Energy (DOE) conducts light-

ing research and provides resources for

implementing energy-ecient lighting. DOE

also conducts voluntary lighting programs

that list lighting guidelines.

Federal Energy Management Program

Solid-State Lighting Solutions has criteria for

ecient fluorescent lamps, ballasts, troers,

and LED troers.

FEMP Acquisition Guidance for Lighting

Products allows users to search for LED

products that have been verified by the LED

Lighting Facts® program and meet the FEMP-

designated performance requirements.

Lighting Controls

Lighting controls like occupancy sensors,

vacancy sensors, and daylight sensors can

signicantly add to the energy savings in

a retrot project. Sensors can be hard-

wired to the xture or wireless and battery-

powered. Many troffer manufacturers

now incorporate one or more controls in

their LED troffer products. However,

sensors don’t work with all retrot

products; see Table 5.

Occupancy sensors reduce the light out-

put when a space is not occupied. They

are most effective for spaces that are used

intermittently. To maximize savings, limit

the time until the setting goes to low set-

ting to the shortest acceptable. Occupancy

sensors can add 28% to savings on

average.

Vacancy sensors are manual-on/auto-off

and should be considered in small private

spaces that are used most of the day.

Daylighting sensors reduce or turn off

electric lighting when sufcient daylight

is available. These sensors can be inte-

grated with occupancy sensors as well.

When daylighting sensors are added to a

Table 5. Controls for Each LED

Troer Retrofit Option

Control

Controls integrated

into device

Available for:

TLED Kit Luminaire

None/few

Some

Many/most

Non-lighting sensors

(e.g., Bluetooth low

energy)

Communication

protocol

Works with wireless

control systems

Dims linearly

Dimming ready

Sensors integrated

into device

GSA replaced 3,300 fluorescent troers

with new LED troers at the Byron G.

Rogers Federal Building in downtown

Denver to gain lighting energy savings of

$49,200 annually. With built-in controls,

the troers can dim down to 0% output in

response to signals from daylight sensors.

Photo source: GSA.

Green Proving Ground Program enables

GSA to make sound investment decisions in

next-generation building technologies based

on their real-world performance.

Interior Lighting Campaign encourages

federal agencies to use energy-ecient

lighting and its website lists several

resources, studies, and factsheets.

U.S. Department of Defense

DoD Unified Facilities Criteria (UFC 3-530)

provides technical criteria for military

construction. UFC 3-530-01, Interior and

Exterior Lighting Systems, includes specific

information about retrofit kits and TLEDs

as well as good general guidance about

lighting.

U.S. General Services Administration

Facilities Standards for the Public Buildings

Service (P100) establishes design standards

and criteria for new buildings, major and

minor alterations, and work in historic struc-

tures for the Public Buildings Service (PBS).

FEDERAL ENERGY MANAGEMENT PROGRAM

8

DOE/EE 1544, PNNL-SA-123952

March 2017

For more information, visit:

energy.gov/eere/femp