Distributed Generation System

Characteristics and Costs in the

Buildings Sector

August 2013

In

dependent Statistics & Analysis

www.eia.gov

U.S. Department of Energy

Washington, DC 20585

U.S. Energy Information Administration | Distributed Generation System Characteristics and Costs in the Buildings Sector i

This report was prepared by the U.S. Energy Information Administration (EIA), the statistical and

analytical agency within the U.S. Department of Energy. By law, EIA’s data, analyses, and forecasts are

independent of approval by any other officer or employee of the United States Government. The views

in this report therefore should not be construed as representing those of the U.S. Department of Energy

or other Federal agencies.

June 2013

U.S. Energy Information Administration | Distributed Generation System Characteristics and Costs in the Buildings Sector 1

Distributed Generation System Characteristics and Costs in the

Buildings Sector

Distributed generation in the residential and commercial buildings sectors refers to the on-site

generation of energy, often electricity from renewable energy systems such as solar photovoltaics (PV)

and small wind turbines. Many factors influence the market for distributed generation, including

government policies at the local, state, and federal level, and project costs, which vary significantly

depending on time, location, size, and application.

As relatively new technologies on the globalized production market, PV and small wind are experiencing

significant cost changes through technological progress and economies of scale. The current and future

equipment costs of renewable distributed generation are subject to uncertainty. As part of the Annual

Energy Outlook (AEO), EIA updates its projections to reflect the most current publicly-available historical

cost data and utilizes multiple third-party estimates of future costs in the near and long terms.

Performance data is likewise based on currently available technology and expert projections of future

technologies.

During the AEO2011 reporting cycle, EIA contracted with an external consultant to develop cost and

performance characterizations of PV and small wind installations in the building sector.

1

Rather than

develop two separate paths for residential and commercial, the contract provided cost and performance

data for systems of various sizes at five-year increments beginning in 2010 and terminating in 2035.

Two levels of future technology optimism were offered, a base case and an advanced case, with the

advanced case including lower equipment costs, higher efficiency, or both.

From this information, EIA used annual weighted-average costs for a typical system size in each sector.

Abbreviated tables of these system sizes and costs are presented in the residential and commercial

chapters of the AEO Assumptions Report in Tables 4.3 and 5.3, respectively. Additional information in

the contracted report, such as equipment degradation rates, system life, annual maintenance costs,

inverter costs, and conversion efficiency, were adapted for input in the Distributed Generation

Submodules of the buildings sectors modules of the National Energy Modeling System.

As described in the assumptions reports, other information not included in the report, such as resource

availability, avoided electricity cost, interconnection limitations, incentive amounts, installed capacity-

based cost reductions, and other factors, ultimately affect the capacity of renewable distributed

generation added within a given sector, year, and Census division.

For editions after AEO2011, certain assumptions (mainly system costs) have been updated based on

reports from the National Renewable Energy Laboratory and Lawrence Berkeley National Laboratory.

Table 1 shows the cost and efficiency assumptions for residential and commercial solar photovoltaic and

small wind systems used in the AEO2010 (published prior to the contract reports), the AEO2011

(published after the contract reports), and the AEO2013.

1

Distributed generation systems often cost more per unit of capacity than utility-scale systems. Another, separate analysis

involves assumptions for electric power generation plant costs for various technologies, including utility-scale photovoltaics and

both on-shore and off-shore wind turbines used in the Electricity Market Module. http://www.eia.gov/forecasts/capitalcost/

June 2013

U.S. Energy Information Administration | Distributed Generation System Characteristics and Costs in the Buildings Sector 2

The solar photovoltaic report, Photovoltaic (PV) Cost and Performance Characteristics for Residential

and Commercial Applications, is available in Appendix A while the small wind report, The Cost and

Performance of Distributed Wind Turbines, 2010-2035, is available in Appendix B. When referencing

these reports they should be cited as reports by ICF International prepared for the U.S. Energy

Information Administration.

June 2013

U.S. Energy Information Administration | Distributed Generation System Characteristics and Costs in the Buildings Sector 3

Table 1: Efficiency and Capital Cost Assumptions for Selected Years

Year

Representative

System Size

(kW)

Electrical

Efficiency

Installed

Capital Cost

($2009/kW

DC)

Electrical

Efficiency

Installed

Capital Cost

($2009/kW

DC)

Electrical

Efficiency

Installed

Capital Cost

($2009/kW

DC)

2010 3.5 0.18 $9,315 0.15 $7,183 0.15 $7,200

2015 4 0.2 $8,042 0.175 $5,346 0.175 $4,965

2020 5 0.22 $6,770 0.192 $4,549 0.192 $3,890

2025 5 0.22 $5,498 0.197 $4,284 0.197 $3,664

2030 5 0.25 $4,225 0.2 $4,102 0.2 $3,508

2035 5

0.25 $4,225 0.2 $4,048 0.2 $3,462

2010 32 0.18 $6,684 0.15 $6,889 0.15 $6,410

2015 35 0.2 $5,893 0.175 $5,109 0.175 $4,475

2020 40

0.22 $5,102 0.192 $4,332 0.192 $3,558

2025 40 0.22 $4,312 0.197 $4,067 0.197 $3,340

2030 45 0.25 $3,521 0.2 $3,890 0.2 $3,195

2035 45 0.25 $3,521

0.2 $3,837 0.2 $3,151

2010

2 0.13 $7,472 0.13 $7,802 0.13 $7,802

2015 3 0.13 $7,106 0.13

$6,983 0.13 $6,983

2020 3 0.13 $6,758

0.13 $6,604 0.13 $6,604

2025 3 0.13 $6,427 0.13

$6,234 0.13 $6,234

2030 4

0.13 $6,111 0.13 $6,051 0.13 $6,051

2035 4 0.13 $6,111 0.13 $5,903 0.13 $5,903

2010

32 0.13 $4,270 0.13 $5,243 0.13 $5,243

2015 35 0.13 $4,061 0.13

$4,715 0.13 $4,715

2020 40 0.13 $3,862

0.13

$4,287 0.13 $4,287

2025

40 0.13

$3,672 0.13 $3,973 0.13 $3,973

2030 50

0.13 $3,492 0.13 $3,717 0.13 $3,717

2035 50 0.13 $3,492 0.13 $3,627 0.13 $3,627

Note: kWDC = kil owa tts of di rect current

Solar

Photovoltaic

Residential

Commercial

Small Wind

Residential

Commercial

AEO2010

AEO2011

AEO2013

June 2013

U.S. Energy Information Administration | Distributed Generation System Characteristics and Costs in the Buildings Sector

APPENDIX A

EIA Task Order No. DE-DT0000804, Subtask 3

Photovoltaic (PV) Cost and

Performance

Characteristics for

Residential and

Commercial Applications

Final Report

August 2010

Prepared for:

Office of Integrated Analysis and Forecasting

U.S. Energy Information Administration

Prepared by:

ICF International

Contact:

Robert Kwartin

T: (703) 934-3586

ii

Table of Contents

Executive Summary......................................................................................................................v

1. Introduction ...........................................................................................................................1

1.1 Objective....................................................................................................................1

1.2 Approach....................................................................................................................1

1.3 Report Organization...................................................................................................2

2. Technologies.........................................................................................................................3

2.1 PV Cell Technology ...................................................................................................3

2.2 Modules & Arrays.......................................................................................................6

2.3 Tracking Technology..................................................................................................7

2.4 Inverters.....................................................................................................................8

2.5 System Efficiency.......................................................................................................9

3. Markets ...............................................................................................................................11

3.1 U.S. Market Perspective ..........................................................................................11

3.2 Installation and Financing ........................................................................................11

3.3 International Market Volatility...................................................................................12

4. Historical Costs ...................................................................................................................13

4.1 Installed PV System Costs.......................................................................................13

4.2 Component Costs ....................................................................................................18

5. Forecast of PV Characteristics – Reference Case..............................................................20

5.1 Technical Performance............................................................................................20

5.2 Cost..........................................................................................................................27

6. Forecast of PV Characteristics – Advanced Case ..............................................................38

References..................................................................................................................................40

Appendix A. Recommended Characteristics, Crystalline PV, Reference Case.......................46

Appendix B. Recommended Characteristics, Thin-film PV, Reference Case..........................47

Appendix C. GDP Implicit Price Deflator Index........................................................................48

iii

Tables

Table 1. PV Prototypes............................................................................................................v

Table 2. PV Prototypes............................................................................................................1

Table 3. Report Organization...................................................................................................2

Table 4. PV Technologies........................................................................................................4

Table 5. Impact of Azimuth and Tilt on Solar Energy ..............................................................8

Table 6. Derate Factors Used in PVWATTS..........................................................................10

Table 7. Relationship of PVWATTS Derate Factors to Efficiency Values..............................10

Table 8. Installed PV in U.S. through 2008............................................................................13

Table 9. Grid Connected PV Coverage in Tracking the Sun II ..............................................13

Table 10. Grid Connected PV Coverage in Tracking the Sun II ..............................................15

Table 11. Rack Mounted Systems Installed in 2008................................................................17

Table 12. Forecast Parameters, Module Efficiency .................................................................21

Table 13. Forecast Parameters, System Efficiency.................................................................23

Table 14. Forecast Parameters, Degradation (% per yr).........................................................24

Table 15. Forecast Parameters, Module and Inverter Lifetime (yrs)........................................25

Table 16. Starting Point Inverter Costs (2008$/kW

DC

).............................................................27

Table 17. Starting Point Costs for Module Plus Other Components (2008$/kW

DC

).................27

Table 18. Forecast Parameters, O&M Costs, (2008$ / kW

DC

/ yr) ...........................................37

Table 19. Crystalline Costs, Reference and Advanced Cases ................................................39

Table 20. Thin-film Costs, Reference and Advanced Cases ...................................................39

iv

Figures

Figure 1. Illustration of Grid-connected PV System..................................................................3

Figure 2. Relationship of PV Cells, Modules, and Arrays.........................................................4

Figure 3. Historical Laboratory Cell Efficiencies – Best Research. ..........................................6

Figure 4. Installed Capacity by State......................................................................................14

Figure 5. Number of Sites by State ........................................................................................15

Figure 6. PV Installed Cost Trends.........................................................................................16

Figure 7. PV Installed Cost Trends by System Size...............................................................17

Figure 8. PV Installed Costs for Crystalline and Thin-film Technologies................................18

Figure 9. Component Costs (systems installed in 2008)........................................................19

Figure 10. Forecast, Module Efficiency, Reference Case ....................................................22

Figure 11. Forecast, System Efficiency, Reference Case ....................................................23

Figure 12. Forecast, Degradation, Reference Case.............................................................24

Figure 13. Forecast, Module and Inverter Life, Reference Case..........................................26

Figure 14. Normalized Cost Trend for PV Modules and Other Components........................28

Figure 15. Cost Projection for 5 kW

DC

Crystalline System....................................................29

Figure 16. Recommended Crystalline Installed Costs, Reference Case..............................30

Figure 17. Recommended Thin-film Installed Costs, Reference Case.................................31

Figure 18. Residential Installed Capital Costs, Reference Case..........................................32

Figure 19. Historical and Forecast Residential Capital Costs...............................................33

Figure 20. Commercial Installed Capital Costs, Reference Case.........................................34

Figure 21. Historical and Forecast Commercial Capital Costs .............................................35

Figure 22. Recommended O&M Costs, Reference Case.....................................................37

Figure 23. Cost Trends for Reference Case and Advanced Case .......................................38

v

Executive Summary

Technical performance and cost characteristics were developed for residential and

commercial photovoltaic (PV) systems for a time horizon extending to 2035.

Characteristics were developed for six typical PV systems shown in Table 1. As

indicated, crystalline and thin-film PV technologies were evaluated in three sizes – 5,

25, and 250 kW

DC

. The 5 kW

DC

size is representative of residential applications, and

the 25 and 250 kW

DC

sizes are representative of commercial installations.

Table 1. PV Prototypes

Application Technology

Size (kW

DC

)

Crystalline 5 Residential

Thin-film 5

25 Crystalline

250

25

Commercial

Thin-film

250

Based on a comprehensive literature search, discussions with PV stakeholders, and

ICF in-house data, the following characteristics were developed:

Module Efficiency

1

System Efficiency

2

Degradation

Life

Installed Capital Costs

O&M Costs

Key results and observations from this study include:

Module Efficiency. Module efficiencies for crystalline technologies operating in the

field are estimated to range from 14% in 2008 to 20% in 2035. For thin-film

technologies, module efficiencies are anticipated to range from 10% to 14% over this

same time span (2008 to 2035).

System Efficiency. System efficiencies (DC to AC power) for crystalline technologies

are expected to increase from levels in the range of 78% to 82% in 2008, to levels in the

range of 86% to 90% in 2035. For thin-film technologies, system efficiencies are

forecast to increase from a range of 77% to 81% in 2008, to a range of 86% to 90% in

2035.

1

In this report, module efficiency refers to the conversion of sunlight to direct current (DC) power.

2

System efficiency refers to the conversion of DC to AC power.

vi

Degradation. Forecast degradation rates for crystalline technologies start at 0.60%/yr

in 2008, and decline to 0.33%/yr in 2035. Forecast degradation rates for thin-film

technologies are higher, ranging from 1.00%/yr in 2008 and falling to 0.73%/yr in 2035.

Lifetime. Crystalline PV modules and balance of plant components (except the

inverter) are forecast to have an expected lifetime of 25 years in 2008. Thin-film

modules and balance of plant components (except the inverter) are forecast to have a

lifetime of 20 years in 2008. Both technologies are forecast to have a lifetime of 30

years by 2035. Inverters, which are assumed to be identical for both crystalline and

thin-film technologies, are forecast to have lifetime of 10 years in 2008, rising to 15

years by 2035.

Residential Installed Capital Costs (expressed in 2008 dollars). For residential

systems, crystalline technologies are forecast to have lower costs compared to thin-film

technologies. Forecast costs for installed residential PV systems are approximately

$7,100/kW

DC

(crystalline) and $7,300/kW

DC

(thin-film) in 2010. These costs fall to

approximately $4,000/kW

DC

(crystalline) and $4,100/kW

DC

(thin-film) by 2035.

Commercial Installed Capital Costs (expressed in 2008 dollars). For commercial

applications, thin-film technologies are forecast to have lower costs compared to

crystalline systems (reverse situation compared to residential systems). In 2010,

forecast costs for installed commercial PV systems are in the range of $5,500/kW

DC

(thin-film, 25 kW

DC

) to $6,800 (crystalline, 25 kW

DC

). By 2035, forecast costs are

estimated to decline to an approximate range of $3,200/kW

DC

(thin-film, 25 kW

DC

and

250 kW

DC

) to $3,800/kW

DC

(crystalline, 25 kW

DC

)

O&M Costs. O&M consists of periodic system inspection and solar panel cleaning. For

forecasting purposes, it is assumed that both commercial and residential PV system

owners will properly maintain their systems. Residential homeowners will likely take a

“do it yourself” approach, while commercial sites will use a maintenance contract. In the

case of a DIY approach, a cost is still incurred in terms of time required to complete the

maintenance. O&M is assumed to scale in direct proportion to panel size, which

decreases as module efficiency increases, and with overall system capacity (decreases

as capacity increases). Crystalline O&M costs are forecast to decline 30% between

2008 and 2035, reaching levels in the range of $11.20/ kW

DC

to $$16.80/kW

DC

by 2035.

For thin-film, forecast costs decline 29%, reaching levels in the range of $16.00/kW

DC

to

$24.80/kW

DC

by 2035.

The recommended characteristics described above correspond to a reference case, or

business-as-usual, scenario. In addition to a reference case analysis, an advanced

case was developed based on more aggressive assumptions concerning technology

advancements and market penetration. The primary difference between the reference

case and the advanced case is that installed capital costs decline more quickly over

time in the advanced case as a result of accelerated R&D investments.

1

1. Introduction

The Energy Information Administration (EIA) produces a wide range of analyses and

reports, including forecasts for energy supply and demand, and the diffusion of

technologies in the marketplace. To develop forecasts, EIA uses the National Energy

Modeling System (NEMS), which is a robust model that describes energy markets in the

United States. Each year, EIA produces the Annual Energy Outlook (AEO), which

includes projections generated with NEMS. The AEO report covers a time horizon of 25

to 30 years, and includes market penetration estimates for a wide range of

technologies, including residential and commercial photovoltaic (PV) systems.

To develop reliable projections using NEMS, it is important to have accurate technical

performance and cost characteristics describing supply side and demand side

technologies. Regarding demand side technologies, the residential and commercial PV

characteristics that EIA has previously used to support NEMS are based on a solar

roadmap baseline projection prepared in 2004.

3

1.1 Objective

The objective of this project was to develop a recommended set of technical

performance and cost characteristics for residential and commercial PV technologies for

the time period extending from 2010 to 2035.

1.2 Approach

ICF conducted a comprehensive literature review and talked with solar experts at

manufacturing organizations, national laboratories, and academic institutions. This

information was analyzed and used to shape a forecast of PV characteristics through

2035. Recommended characteristics were developed for six PV system prototypes as

shown in

Table 2

. The 5 kW

DC

size is intended to be representative of residential

applications, and the 25 and 250 kW

DC

capacities are consistent with commercial

installations (25 kW

DC

at the low end, and 250 kW

DC

at the high end).

Table 2. PV Prototypes

Capacity (kW

DC

)

4

Technology

5, 25, 250 Crystalline

5, 25, 250 Thin-film

As indicated in

Table 2

, the prototypes are based on crystalline and thin-film solar cell

technology. Multi-junction technologies were also evaluated. However, multi-junction

technologies are not expected to have significant market penetration in residential and

3

Our Solar Power Future, The U.S. Photovoltaics Industry Roadmap Through 2030 and Beyond,

September 2004.

4

Unless noted otherwise, all PV power ratings (kW

DC

) in this report are based on direct current (DC) at

standard test conditions (STC). Standard test conditions are 1,000 W/m

2

of solar irradiance, cell

temperature of 25

o

C, and air mass (AM) of 1.5.

2

commercial applications in the foreseeable future, and prototypes were therefore based

only on crystalline and thin-film systems.

Using the prototypes shown in

Table 2

, a set of recommended PV characteristics was

developed that is consistent with a reference case scenario. The reference case

scenario is intended to reflect a business-as-usual outcome, assuming that the current

pace of R&D investments and policy drivers will prevail over the forecast time horizon.

In addition to the reference case scenario, a set of recommended PV characteristics

was also developed for an advanced case. The advanced case is based on a scenario

that includes higher levels of R&D investments that may accelerate the adoption of

residential and commercial PV.

1.3 Report Organization

This report is organized as shown in

Table 3

. An overview of PV technologies is

provided in Section 2, followed by a discussion of markets in Section 3. Historical cost

trends from 1998 through 2008 are covered in Section 4. In Section 5, PV

characteristics used in the AEO 2010 report are discussed. Results from discussions

with PV experts and the literature search are presented in Section 6. In Section 7,

recommended PV characteristics for a reference case are presented, and in Section 8

characteristics for an advanced case are described.

Table 3. Report Organization

Section Title

1 Introduction

2 Technologies

3 Markets

4 Historical Costs

5 Forecast of PV Characteristics – Reference Case

6 Forecast of PV Characteristics – Advanced Case

3

2. Technologies

For residential and commercial PV applications, the two main components are a PV

array (also called solar array) and an inverter. A third component in many PV

installations is bank of batteries for energy storage. The PV array produces direct

current (DC) from sunlight, and the inverter converts the direct current to alternating

(AC) current. The AC power is then used on site or exported to the grid. A simplified

schematic for a residential PV installation is shown in

Figure 1

(no battery backup).

Source: Homepower magazine

Figure 1. Illustration of Grid-connected PV System

Residential and commercial PV systems can be connected to the grid or configured as

an off-grid system. Off-grid installations are typically only used in remote locations, and

have little or no impact on the national energy forecast; as a result, this report is focused

on grid-connected PV only.

In this section, key components of a PV system are discussed, including the current

status and development trends. The discussion is organized into the following sections:

PV Cells

Modules & Arrays

Tracking Systems

Inverters

System Efficiency

2.1 PV Cell Technology

The building block for a PV system is a PV cell (or solar cell). Multiple PV cells are

interconnected and assembled in a support structure, or frame, to form a PV module (or

solar panel). Multiple modules are then combined to form a PV array (see

Figure 2

).

DC Power AC Power

Sunlight

4

Source: NASA

Figure 2. Relationship of PV Cells, Modules, and Arrays

Photovoltaic (PV) technologies are constructed using semiconductor materials that have

the ability to convert sunlight into electricity. PV technologies are typically divided into

three categories – crystalline silicon, thin-film, and multi-junction (see

Table 4

).

Table 4. PV Technologies

Category Semiconductor Material

Crystalline Silicon ---

Cadmium Telluride (CdTe)

Gallium Arsenide (GaAS)

Copper Indium Gallium Diselenide (CIGS)

Thin-film

Amorphous Silicon (a-SI)

Multi-junction ---

Of the three categories, crystalline technologies are the oldest, and were

commercialized by Bell Labs in the 1950s. Crystalline PV cells are manufactured by

slicing silicon into thin wafers, with state-of-the-art technology near 170 microns (Shah

2009). There are two types of crystalline cells – monocrystalline and polycrystalline.

Compared to polycrystalline cells, monocrystalline cells offer higher efficiencies, but are

more expensive to manufacture. Polycrystalline cells have lower efficiencies, but are

lest expensive to manufacture.

Thin-film PV cells are produced by depositing very thin layers of a semiconductor

material on an inexpensive substrate, such as glass, plastic, or metal.

Table 4

shows

four common types of semiconductor materials that are used in thin-film PV cells.

Compared to crystalline technologies, thin-film cells are typically less expensive to

manufacture, but tend to have lower efficiencies.

5

Multi-junction cells are fabricated using thin-film techniques, but have two or more

different semiconductor materials. The semiconductor materials in a multi-junction cell

capture solar energy from different ranges of the solar spectrum, thereby optimizing the

conversion of solar energy to electricity. Compared to crystalline and thin-film

technologies, multi-junction cells are significantly more expensive to manufacture. Due

to the high cost, multi-junction cells do not currently compete in residential and

commercial markets.

Crystalline Technology – Trends and Observations

Crystalline modules have dominated residential and commercial PV markets.

Crystalline cell efficiencies in the field have improved from approximately 11% to over

14% over the past five years (Shah 2009, Barnett 2009).

,

Efficiencies in the lab, which

are higher than efficiencies in the field, have reached 26% under standard test

conditions (STC) (Green 2009).

In recent years, the silicon wafer thickness has been reduced from approximately 300 to

170 microns, and manufacturers have generally increased warranty times from 20 to 25

years. Crystalline cell research is currently focused on reducing material costs,

increasing efficiencies, improving the manufacturing processes, and improving reliability

of modules (DOE 2008).

Thin-film Technology – Observations and Trends

Over the past five years, thin-film efficiencies have increased from the range of 5-8% to

approximately 10% (Barnett 2009).

The thin-film market is currently dominated by

modules using cadmium telluride (CdTe) as a semiconductor (Maycock and Bradford

2007; Ullal and von Roedern 2007; Venkataraman 2009). In the lab, CdTe modules

have reached efficiencies greater than 16% (Green 2009). Two emerging thin-film

technologies are copper indium diselenide (CIS) and copper indium gallium diselenide

(CIGS). These two cell technologies have shown lab efficiencies of approximately 19%

(Green 2009).

Another thin-film technology is based on the deposition of amorphous

silicon (a-Si) less than a micron thick (Maycock and Bradford 2007). One advantage of

a-Si is that these cells can be manufactured in long continuous rolls rather than by

batch production (Maycock and Bradford 2007).

Thin-film technologies continue to undergo advancements. CdTe manufacturers are

working to standardize film growth equipment, achieve higher efficiencies, and prevent

moisture ingress (Ullal 2007). CIGS manufacturers are developing standardized layer

deposition equipment and working to achieve higher efficiencies and reduced layer

thicknesses (Ullal 2007).

Cell Efficiency – Observations and Trends

As indicated in

Figure 3

, solar cell efficiencies have increased at a steady rate over the

last several decades (DOE 2006). Efficiencies for advanced multi-junction technologies

have approached 40% in laboratory settings at STC conditions. However, efficiencies

6

for practical cells, such as crystalline and thin film technologies, are well below these

levels in the field.

Source: NREL (2010)

Figure 3. Historical Laboratory Cell Efficiencies – Best Research.

2.2 Modules & Arrays

Optimizing Performance

Several environmental factors contribute to system output losses, including sub-optimal

orientation with respect to the sun, soiling, shading, and seasonal snow cover. The

soiling factor is the percent of output lost by dirt or any other film that obscures the

module surface, and ranges from slightly under 1% to 4% (Xantrex 2009).

The amount

of soiling depends on factors such as physical location (proximity to dusty roads, etc.),

type of dust or film, and length of time since the last rainfall. Regular cleaning

minimizes the impact of soiling (Xantrex 2009).

PV modules are connected in series, and a mismatch in electrical output between

modules will decrease the electrical production of the PV array. Electrical mismatch can

occur due to shading from buildings, trees, or other obstacles that interfere with direct

sunlight striking the solar array. The magnitude of the mismatch depends on the array

area affected, length of time, and time of day (Xantrex 2009). In colder climates,

seasonal snow cover also shades systems and leads to mismatch. All of these factors

need to be taken into account when estimating conversion losses of a PV system.

7

The electrical efficiency of a solar cell in the lab under Standard Test Conditions (STC)

is almost always higher than the field efficiency, in part due to temperature differences.

For STC measurements, the solar cell is held at 25

o

C. The efficiency of a solar cell

decreases with increasing temperature, and the field temperature of a solar cell is

almost always higher than 25

o

C. Roof mounted arrays can reach temperatures of 70-

80

o

C (Wiles 2009). For rooftop conditions, the California Energy Commission

recommends a de-rating factor of 89% from STC lab conditions to expected field power

(Xantrex 2009).

Building Integrated PV (BIPV)

This report is primarily focused on PV panels that are rack mounted. However, an

interesting development is the growth of building integrated PV (BIPV). BIPV

technologies are currently more expensive than rack mounted systems, but BIPV

breakthroughs could push down PV costs in residential and commercial applications

(Chiras 2009).

2.3 Tracking Technology

Maximum PV output occurs when a solar panel is oriented perpendicular to incoming

sunlight. The optimum orientation changes through the day as the sun moves across

the sky, and on a seasonal basis as the height of the sun above the horizon changes.

Tracking systems can be added to PV arrays to optimize electrical output.

In most residential applications, PV panels are placed on roof tops in fixed frames (also

called “racks”), and tracking systems are not utilized. When the panels are located

directly on the roof top, they are referred to as “flat racked” systems. Unless the roof is

pitched at the local latitude angle, the system’s power output can be increased by tilting

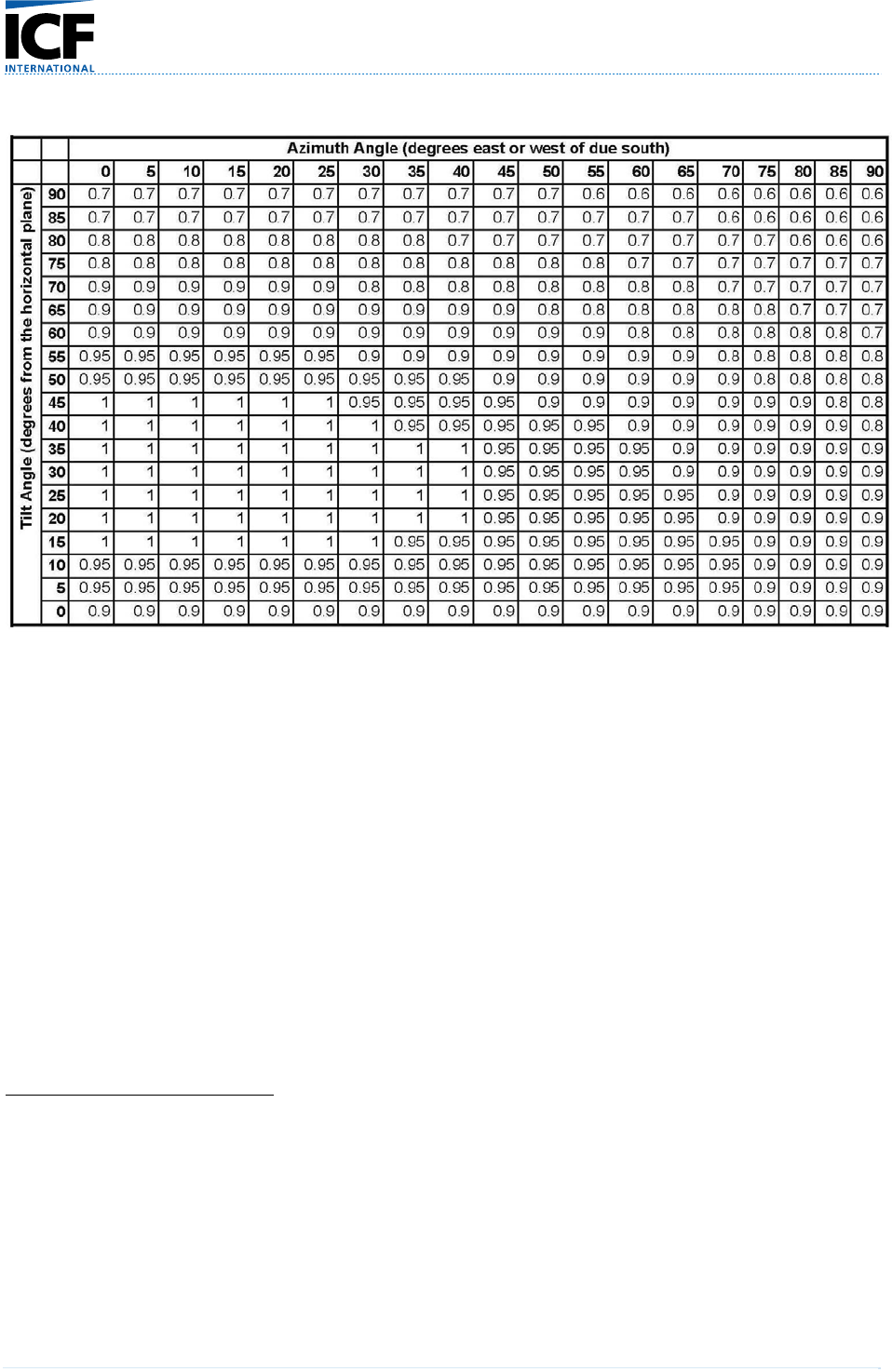

the racking to be closer to the latitude angle to capture more sunlight (see

Table 5

).

This type of tilting is referred to as “latitude racking.”

Latitude racking is more expensive than flat-racking for both the residential and

commercial sectors. Compared to flat-racked systems, significantly more hardware,

assembly, and labor is involved in latitude racked systems. However, there is a

financial trade off to consider. Even though flat-racking costs less, the modules are 20-

30% less efficient than latitude racked systems (Focusing on Energy 2008).

In addition to static latitude racking, more sophisticated dynamic tracking systems can

be used. Dynamic tracking systems can be either single-axis or dual-axis designs. A

single axis design follows the daily east-west arc of the sun. With a dual axis system,

hourly tracking (east-west) is achieved as well as seasonal tracking (north-south).

8

Table 5. Impact of Azimuth and Tilt on Solar Energy

5

2.4 Inverters

PV arrays produce direct current (DC) from sunlight; and this DC current is converted to

alternating (AC) current with an inverter. Inverters are not 100% efficient, and energy is

lost during this conversion process.

Today, the highest inverter conversion efficiency of DC to AC power is 96-97%,

compared to approximately 94% in the 2004 time frame (Waiter 2009). In practice,

typical inverter efficiencies in the field range from 92% to over 94% (Shah 2009).

Residential inverters are smaller and slightly less efficient than larger scale commercial

inverters, which leads to larger conversion losses in the residential sector (Shah 2009).

For a PV system that includes battery energy storage, there are additional energy

losses that occur as batteries are charged and discharged. The battery efficiency,

which is often referred to as the “roundtrip” efficiency, depends on several factors,

including the type of battery (e.g., lead acid or nickel cadmium) and the state of charge

5

This table is derived from the NREL Surface Orientation Factor charts in: Christensen, Craig B.

and Greg M. Barker. Effects of Tilt and Azimuth Angle on Annual Incident Solar Radiation for

United States Locations. Washington, DC: Proceedings of Solar Forum 2001 – Solar Energy:

The Power to Choose, April 21-25, 2001. The table is presented for a latitude of approximately

32

o

N.

9

(i.e., near full charge or at some lower charge level). Deep discharge lead acid

batteries are frequently used for PV applications, and these batteries have a roundtrip

efficiency level typically near 80% (i.e., 80% of the energy used to charge the battery is

available for discharge).

A common configuration for residential and commercial PV systems is to use a single

inverter (see Figure 1) located near the electrical service panel for the building. PV

systems that use multiple inverters – referred to as microinverters – are entering the

market. Microinverters convert DC to AC power in a unit attached directly to each PV

module, instead of through a single stand-alone inverter that serves the entire PV array.

Microinverters are an emerging technology, and there is limited data available to assess

actual performance and costs. However, potential advantages of microinverters may

include:

Increased reliability. A separate inverter for each module means there is no

single point of failure. If one microinverter fails, other modules continue to

operate.

Longer life. Enphase, a manufacturer of microinverters, reports that their

microinverters are designed for a service life greater than 20 years.

6

Improved performance of each module. A separate microinverter on each

module maximizes performance of that module.

Lower installation costs. Simplified installation with no wiring required for a

central inverter.

2.5 System Efficiency

Inverters are just one source of power loss when converting from DC to AC power. An

example of other factors that contribute to power losses in PV systems is shown in

Table 6. This table, which is taken from NREL data used in the PVWATTS tool, shows

that there are 10 factors in addition to the inverter that may contribute to power losses.

For the default values in the PVWATTS tool, the inverter derate factor is 0.92 and the

overall derate factor is 0.77.

In this report, a detailed analysis and forecast of derate factors, or efficiency losses, by

component, was not conducted. Rather, the analysis and forecast was divided into two

categories:

System efficiency (includes all factors that contribute to DC to AC power with

the exception of age)

Degradation (accounts for power losses that occur due to the age of the

system)

6

Enphase web site,

http://www.enphaseenergy.net/downloads/Enphase_WhitePaper_Reliability_of_Enphase_Micro-

inverters.pdf , accessed March 2010.

10

A cross map of PVWATTS derate factors and efficiency factors used in this report is

show in Table 7.

Table 6. Derate Factors Used in PVWATTS

Component Derate Factors PVWATTS Default Range

PV module nameplate DC rating 0.95 0.80 - 1.05

Inverter and Transformer 0.92 0.88 - 0.98

Mismatch 0.98 0.97 – 0.995

Diodes and connections 1.00 0.99 – 0.997

DC wiring 0.98 0.97 - 0.99

AC wiring 0.99 0.98 – 0.993

Soiling 0.95 0.30 – 0.995

System availability 0.98 0.00 – 0.995

Shading 1.00 0.00 - 1.00

Sun-tracking 1.00 0.95 - 1.00

Age 1.00 0.70 - 1.00

Overall DC-to-AC derate factor 0.77 ---

Source: NREL PVWATTS, http://rredc.nrel.gov/solar/calculators/PVWATTS/system.html

Table 7. Relationship of PVWATTS Derate Factors to Efficiency Values

Derate Component in PVWATTS Efficiency Component in this Report

PV module nameplate DC rating

Inverter and Transformer

Mismatch

Diodes and connections

DC wiring

AC wiring

Soiling

System availability

Shading

Sun-tracking

System Efficiency (changes by year,

cell material, and capacity)

Age Degradation Rate (changes by year and

PV cell material)

11

3. Markets

3.1 U.S. Market Perspective

Federal, state, and utility incentives provide strong drivers that push the adoption of PV

systems. At the Federal level, there is an investment tax credit (ITC), which provides an

income tax credit for residential and commercial PV installations. The ITC was revised

in 2009 as part of the American Recovery and Reinvestment Act (ARRA). ITC

provisions in ARRA that specifically relate to PV include:

30% ITC extended through end of 2016 for both residential and commercial

solar installations

$2,000 cap eliminated for residential PV

Utilities allowed to benefit from credit (utilities were previously excluded)

Tax payers (both individuals and businesses) that are required to file

Alternative Minimum Tax (AMT) are allowed to claim credit (previously

excluded)

PV market size, maturity, and total installed costs vary widely from state to state. The

growth of residential and commercial PV markets within a state has been driven almost

entirely by state-based incentive programs (Venkataraman 2009).

The overwhelming

majority of residential and commercial PV installations have occurred in just two states

– California and New Jersey (Wiser 2009). Both of these states have well developed

incentive programs that have stimulated PV adoption.

In addition to capacity based incentives and performance based incentives, states have

used a variety of other tools to encourage the installation of PV, including sales and

property tax exemptions, net metering laws, feed-in tariffs, solar access laws,

standardized and liberalized interconnection procedures, etc. The incentive mix

changes continuously; refer to the Database of State Incentives for Renewables and

Efficiency (DSIRE) for the most recent information (DSIRE 2009).

3.2 Installation and Financing

Historically, the installation of PV systems has been performed by companies that

specialize in PV. However, the drop in demand for new construction and building

retrofit work, coupled with growing demand for end-use PV, has motivated construction

companies, roofing contractors, and electrical contractors to enter the PV installation

business (Shah 2009).

With their project management and business experience, these

companies are streamlining the installation process and increasing competition within

the industry.

In addition, new financing methods have begun to emerge that are encouraging the

adoption of PV systems. The financial factors that influence a consumer’s decision to

purchase include upfront costs, financial incentives, utility bill savings, and maintenance

costs. Due to the current weak economic conditions, residential homeowners and

12

commercial building owners/developers are reluctant to make expensive capital

investments such as PV (Coughlin 2009). New financing methods, such as the

commercial solar power purchase agreement (SPPA) and the residential solar lease,

seek to overcome these financial barriers by significantly reducing or eliminating the

upfront cost to commercial and residential customers (Coughlin 2009).

3.3 International Market Volatility

The U.S. PV industry is influenced by the volatility of the larger international solar

market. Manufacturers focus their attention, and their sales, on the fastest growing and

most profitable markets. For example, Spain’s feed-in tariff motivated rapid growth and

made Spain the largest PV market in the world in 2008. Unprecedented demand in

Spain put a strain on global supply that kept equipment costs high in the U.S. and

elsewhere in the world (Tarbell 2009). Growth in Spain has slowed recently, but growth

in other markets has picked up. For example, Germany installed 3.8 GW of PV in 2009,

and 1.45 GW in December alone.

7

7

http://www.pv-tech.org/lib/printable/8828, accessed May 2010.

13

4. Historical Costs

Historical costs for PV systems are discussed in this section, which is organized as

follows:

Installed PV System Costs

Component Costs

4.1 Installed PV System Costs

Technological developments across the PV supply chain, from commodities to

efficiencies, have pushed total installed costs downward. An increase in silicon

manufacturing has increased supply and lowered the price of silicon in crystalline PV

modules (Hasan 2009).

Improved manufacturing processes have increased the

production output of facilities, while decreasing the costs of production (GT Solar 2009).

In recent years, streamlined manufacturing has led to decreased manufacturing costs.

Machine manufacturers have begun to offer turn-key production lines which are

complete manufacturing system packages. Turn-key solutions are sold for every stage

of the supply chain, from wafer fabrication to module fabrication (GT Solar 2009). These

automated turn-key production lines have helped increase productivity, quality, and

yields, while lowering manufacturing costs. Automated systems have also made it

easier for new firms to enter the manufacturing arena, thereby increasing competition

and putting downward pressure on prices.

A recent report titled “Tracking the Sun II” by Lawrence Berkeley National Laboratory

summarizes the installed cost of PV systems in the United State from 1998 through

2008. Costs in this report cover approximately 52,000 residential and non-residential

systems, with a total capacity of 566 MW (71% of grid connected capacity in the United

States at the end of 2008). PV installed capacity and coverage as reported in Tracking

the Sun II are shown in

Table 8

and

Table 9

, respectively.

Table 8. Installed PV in U.S. through 2008

Capacity Type of Installation

(MW) (%)

Grid Connected 798 88%

Off Grid 109 12%

Total 906 100%

Table 9. Grid Connected PV Coverage in Tracking the Sun II

Capacity

(MW) (% of all grid

connected)

(% of all PV)

Covered in TS II 566 71% 62%

Not Covered in TS II 231 29% 26%

Total Grid Connected 798 100% 88%

14

PV system data reported in Tracking the Sun II was collected from 16 states. A

comparison of the PV installed capacity across the 16 states is shown in

Figure 4

, and

a comparison of the number of PV installations by state is shown in

Figure 5

. As

indicated, California has the highest representation in the sample, followed by New

Jersey.

AZ

1%

MA

1%

CT

2%

NY

1%

Other 10 States

2%

NJ

11%

CA

82%

Figure 4. Installed Capacity by State

15

NY

2%

AZ

2%

MA

2%

CT

1%

NJ

6%

Other 10 States

5%

CA

82%

Figure 5. Number of Sites by State

Average annual costs for all PV systems in the LBNL sample are shown in

Table 10

and graphed in

Figure 6.

These data are based on all system types in the data sample

(e.g., rack-mounted, building integrated, tracking, non-tracking, crystalline, thin-film,

etc.). As indicated in the table, the simple average of PV installed costs has declined

from $12,260/kW

DC

in 1998 to $8,243 in 2008 (a total decrease of 33%, or 3.9% per

year).

Table 10. Grid Connected PV Coverage in Tracking the Sun II

Installed Cost (2008$ / kW

DC

) Year

Number of

Systems

Capacity (MW)

Capacity Weighted Simple Average

1998 39 0.2 10,849 12,260

1999 180 0.8 10,600 11,611

2000 217 0.9 9,485 10,900

2001 1,308 5.4 9,768 10,492

2002 2,489 15.0 9,754 10,455

2003 3,526 34.0 8,370 9,308

2004 5,527 44.0 8,287 8,566

2005 5,193 57.0 7,770 8,264

2006 8,677 90.0 7,838 8,385

2007 12,103 122.0 7,837 8,474

2008 13,097 197.0 7,480 8,243

52,356 566.3

16

$0

$2,000

$4,000

$6,000

$8,000

$10,000

$12,000

$14,000

1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 2008

Year

Installed Cost (2008$ / kW

DC

)

Capacity Weighted

Simple Average

Figure 6. PV Installed Cost Trends

Figure 7 shows a breakout of historical PV costs by size range. Systems less than 100

kW

DC

showed a steady decline from 1998 through about 2005, and then remained

generally flat from 2005 through 2007, followed by a decline in installed costs for 2008.

Compared to systems under 100 kW

DC

, there are far fewer systems with capacities

above 100 kW

DC

, and the data are somewhat more scattered for these larger systems.

However, based on Figure 7, it is clear that there are economies of scale, with larger

systems consistently showing lower costs.

17

$0

$2,000

$4,000

$6,000

$8,000

$10,000

$12,000

$14,000

1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 2008

Installation Year

Average Installed Cost (2008$ / kW

DC

)

<5 kW

5-10 kW

10-100 kW

100-500 kW

>500 kW

Figure 7. PV Installed Cost Trends by System Size

Table 11

shows average costs for rack mounted PV technologies in 2008 with a

breakdown for crystalline and thin-film technologies in three size categories. In 2008,

similar to other years, the majority of PV installations have used rack mounted

crystalline technology. In 2008, over 10,500 rack mounted crystalline systems were

installed, representing 80% of the total PV installations tracked by LBNL in 2008

(13,097 total systems in 2008).

Table 11. Rack Mounted Systems Installed in 2008

Technology

Crystalline Thin-film

Size

Number of

Systems

Capacity

(MW)

Cost

(2008$/kW

DC

)

Number of

Systems

Capacity

(MW)

Cost

(2008$/kW

DC

)

< 10 kW

DC

9,179 43 8,200 22 0.1 8,500

10-100 kW

DC

1,098 24 7,900 16 0.7 6,400

>100 kW

DC

242 86 7,200 6 2.4 6,700

10,519 153

44 3.2

Compared to the population of crystalline systems, LBNL identified far fewer rack

mounted thin-film installations. As indicated in

Table 11

, there are only 44 total thin film

systems identified in all three size categories, with a combined capacity of 3.2 MW.

18

While the cost numbers for the thin-film systems seem reasonable (range from

$6,400/kW

DC

to $8,500/kW

DC

), these results should be viewed with caution given the

small sample size. The cost numbers for thin-film technologies could change

significantly as the sample size grows and becomes more statistically relevant.

Figure 8

compares the average costs for crystalline and thin-film technologies by the

three size categories. For systems <10 kW

DC

, crystalline technologies show slightly

lower costs -- $8,200/kW

DC

for crystalline compared to $8,500 for thin-film. However,

for systems >10 kW

DC

, thin-film technologies have lower costs. In the 10-100 kW

DC

size

range, the cost differential is $1,500/kW

DC

($7,900/kW

DC

compared to $6,400/kW

DC

),

and in the >100 kW

DC

size range the differential is $500/kW

DC

($7,200/kW

DC

compared

to $6,700/kW

DC

).

8,200

7,900

7,200

8,500

6,400

6,700

0

1,000

2,000

3,000

4,000

5,000

6,000

7,000

8,000

9,000

10,000

< 10 kW 10-100 kW >100 kW

Size

Cost (2008$/kW

DC

)

Crystalline

Thin Film

Figure 8. PV Installed Costs for Crystalline and Thin-film Technologies

4.2 Component Costs

Component level cost data are scarce. However, in Tracking the Sun II component

costs are reported for a single year (2008) as shown in

Figure 9

. The costs in this

figure are average costs for crystalline and thin-film technologies combined. The costs

19

are separated into three different size ranges – 1) under 10 kW

DC

, 2) 10-100 kW

DC

, and

3) >100 kW

DC

.

$4,600

$4,500

$3,900

$2,900

$2,600

$2,800

$500

$600

$700

$0

$1,000

$2,000

$3,000

$4,000

$5,000

$6,000

$7,000

$8,000

$9,000

<10 kW 10-100 kW >100 kW

Size

Average Cost (2008$ / kW

DC

)

Other

Inverter

Module

(56%)

(9%)

(35%)

(58%)

(8%)

(34%)

(54%)

(7%)

(39%)

Figure 9. Component Costs (systems installed in 2008)

As indicated in

Figure 9

, module costs account for the largest fraction of PV installed

costs, ranging from 54% to 58% of the average total installed cost. Module costs are

$600 to $700/kW

DC

lower for systems over 100 kW

DC

compared to the two small size

bins, which suggests that there are may be bulk purchasing discounts that help reduce

module costs for large systems.

Based on 2008 system data in the LBNL Tracking the Sun II report, inverters account

for 7% to 9% of the total installed cost. As system sizes increase, inverter costs show

declining costs (decline from $700/kW

DC

in smallest size bin to $500/kW

DC

in largest

size bin). A report prepared by Navigant for NREL (NREL 2006) offers additional

insights into inverter costs. In this report, which is based on data from 2006, inverters

are estimated to account for 10-20% of the initial PV system installed cost (higher than

the 7-9% reported by LBNL in 2008)

In

Figure 9

, the “other” category includes costs associated with design, engineering,

installation labor, and regulatory compliance. These other expenses account for a third

or more of total installed costs (range from 34% to 39% depending on PV size).

20

5. Forecast of PV Characteristics – Reference Case

While there is ample research and analysis on the size and scope of the PV market,

there are few detailed forecasts regarding PV costs and technical performance in the

public domain. To develop a PV forecast, ICF collected information from several

sources, including interviews with industry PV stakeholders, publicly available literature,

and in-house ICF data. The data were grouped into three capacities (5, 25, and 250

kW

DC

) and two technology types (crystalline and thin-film), resulting in six unique PV

technology categories.

No rigid formula was used to develop a composite industry forecast of PV technical

performance and cost characteristics. Rather, all data were examined, and data that

appeared to lie well outside norms were excluded. The remaining data were further

examined and ICF forecasts were developed.

The characteristics described in this section correspond to a reference case scenario

consistent with the assumptions used for the reference case described in the AEO 2010

report. The discussion of recommended reference case characteristics is organized as

follows:

Technical Performance

o Module Efficiency

o System Efficiency

o Degradation

o Lifetime

Cost

o Component Costs (including inverter)

o Installed Capital

o O&M

For reference, tables with selected results for the reference case are shown in

Appendix A (crystalline technologies) and Appendix B (thin-film technologies). In

these tables, and elsewhere in this report, costs are reported in 2008 dollars unless

noted otherwise. Conversions between dollar years, if necessary, have been calculated

using a gross domestic product (GDP) index shown in Appendix C.

5.1 Technical Performance

5.1.1 Module Efficiency

Module efficiencies are primarily dependent on the type of solar cell, and no significant

efficiency differences are expected for different capacities. However, different efficiency

curves are expected for crystalline and thin-film technologies.

21

To develop a forecast, ICF estimated values for module efficiency when installed in the

year 2008, and then looked at potential upper limits. A range of module efficiencies

were examined from manufacturers, industry experts, and research reports. Based on

this review, ICF selected an average crystalline module efficiency in 2008 of 14%, and

an average thin-film module efficiency of 10%. The analysis also suggested that a

reasonable upper limit for crystalline modules is 20%, and a reasonable upper limit for

thin-film is 14%.

Note that these module efficiencies are based on field performance, and not laboratory

measurements. Laboratory measurements conducted at standard test conditions

almost always exceed average field performance values.

Linear improvement rates were then developed to connect the starting values and end

points. The improvement rates were adjusted by “eye” to achieve a smooth transition

over time. The module efficiency forecast parameters are shown in Table 12, and the

resulting values are shown in Figure 10.

Table 12. Forecast Parameters, Module Efficiency

PV Cell Technology

Crystalline Thin-film

Starting Value (2008) 14% (0.140) 10% (0.100)

Annual Change +0.005 thru 2018 +0.002 thru 2028

+0.001 thru 2028 ---

no change after 2028 no change after 2028

Value in 2035 20% 14%

22

0%

5%

10%

15%

20%

25%

2005 2010 2015 2020 2025 2030 2035

Year

Module Efficiency (%)

Crystalline

Thin-film

Figure 10. Forecast, Module Efficiency, Reference Case

5.1.2 System Efficiency

The overall efficiency of a PV system is determined by several factors, including inverter

losses, resistance of wires and connectors, soiling, and module mismatch. While these

factors affect all types of PV systems, there are also differences between PV system

types. Residential inverters are smaller and therefore less efficient than commercial

inverters, leading to generally lower system efficiencies in residential PV technologies

(all other factors being equal).

Similar to module efficiencies, linear improvement rates were developed to connect

starting values and end points. The improvement rates were adjusted to achieve a

smooth transition over time. The system efficiency forecast parameters are shown in

Table 13, and the resulting system efficiency curves are shown in Figure 11.

23

Table 13. Forecast Parameters, System Efficiency

PV Cell Technology

Crystalline Thin-film

5 kW 25 kW 250 kW 5 kW 25 kW 250 kW

Starting

Value (2008)

78% 80% 82% 77% 79% 81%

+0.01 thru 2012 +0.01 thru 2012

+0.005 thru 2020 +0.005 thru 2022

Annual

Change

no change after 2020 no change after 2022

Value in

2035

86% 88% 90% 86% 88% 90%

As indicated, crystalline system efficiencies are expected to increase from levels in the

range of 78% to 82% in 2008, to levels in the range of 86% to 90% in 2035. For thin-film

technologies, the efficiencies increase from the range of 77% to 81% in 2008, to 86%to

90% by 2035 (same end point for thin film as crystalline).

75%

80%

85%

90%

95%

100%

0 5 10 15 20 25 30

Year

System Efficiency (%)

Crystalline, 5 kW

Crystalline, 25 kW

Crystalline, 250 kW

Thin-film, 5 kW

Thin-film, 25 kW

Thin-film, 250 kW

Figure 11. Forecast, System Efficiency, Reference Case

24

5.1.3 Degradation

PV modules typically lose capacity over time as a result of UV effects on construction

materials and other aging factors. The rate at which modules lose capacity is

debatable. However, based on sources consulted for this report ICF selected the

starting values and annual change rates shown in Table 14. Based on these

parameters, the resulting degradation curves are shown in Figure 12.

Table 14. Forecast Parameters, Degradation (% per yr)

PV Cell Technology

Crystalline Thin-film

Starting Value (2008) 0.60% (0.0060) 1.00% (0.1000)

Annual Change -0.0001 thru 2035

Value in 2035 0.33% 0.73%

0.0%

0.1%

0.2%

0.3%

0.4%

0.5%

0.6%

0.7%

0.8%

0.9%

1.0%

2005 2010 2015 2020 2025 2030 2035 2040

Year

Degradation (% / yr)

Crysalline

Thin-film

Figure 12. Forecast, Degradation, Reference Case

In the ICF forecast, the degradation rate for crystalline technologies declines by about

45% between 2008 and 2035 (0.60% to 0.33%), and by about 27% for thin film

technologies (1.00% to 0.73%). Over the forecast horizon, thin-film degradation rates

are held higher than crystalline technologies.

25

Thin-film technologies have a higher surface area than crystalline systems for

equivalent rated capacity, and a higher surface area could contribute to higher

degradation rates. However, in general, there are no fundamental reasons that thin-film

systems should have higher degradation rates than crystalline systems. However,

compared to crystalline technologies, there are fewer thin-film technologies currently

being used in residential and commercial applications. The higher degradation rate for

thin-film technologies is a conservative value based on a smaller data set with

potentially unknown or not-well characterized degradation factors.

5.1.4 Lifetime

Thin-film technologies are relatively new, and there is little field experience data

available to support lifetime projections. However, for forecasting purposes, ICF

assumed that thin-film systems would follow similar lifetime trends as more mature

crystalline technologies, but lag behind in terms of the time required to achieve these

lifetime estimates. For crystalline technologies, ICF developed the forecasting

parameters shown in Table 15. This table also shows the forecasting parameters

developed for thin-film technologies and inverters.

Table 15. Forecast Parameters, Module and Inverter Lifetime (yrs)

PV Cell Technology

Crystalline Thin-film

Inverter

Starting Value (2008) 25 yrs 20 yrs 10 yrs

Annual Change + 0.5 yrs thru 2018 + 0.5 yrs thru 2018 + 0.5 yrs thru 2018

+ 0.5 yrs thru 2018 + 0.5 yrs thru 2018 + 0.5 yrs thru 2018

no change after 2018

no change after

2028

no change after

2018

Value in 2035 30 yrs 30 yrs 15 yrs

Lifetime forecasts are shown in Figure 13. As indicated, the lifetime of thin-film

modules is forecast to lag crystalline modules through 2028. From 2028 onward, the

lifetime for both technologies is assumed to be 30 years. For forecasting purposes,

ICF is estimating that average inverter lifetimes will start at 10 years in 2008, and

increase to 15 years by 2018.

26

0

5

10

15

20

25

30

35

2005 2010 2015 2020 2025 2030 2035 2040

Year

Lifetime (yrs)

Crystalline

Thin-film

Inverter

Figure 13. Forecast, Module and Inverter Life, Reference Case

27

5.2 Cost

Long term cost projections for residential and commercial PV installations are scarce in

the literature. However, industry stakeholders did provide opinions on long term cost

trends. These opinions were combined with ICF in-house data to develop cost

projections, which are provided in the following subsections:

Component costs (including inverters)

Installed capital costs

O&M costs

5.2.1 Component Costs

For forecasting purposes, PV components were divided into three categories

Module

Inverter

Other (installation labor, regulatory compliance, and overhead)

ICF set the starting point costs for inverters to be consistent with data reported in the

LBNL Tracking the Sun II report (see Figure 9). These inverter starting point costs are

shown in Table 16.

Table 16. Starting Point Inverter Costs (2008$/kW

DC

)

Cost by System Size ($/kW

DC

) – same for crystalline and thin-film

5 kW

DC

25 kW

DC

250 kW

DC

$700 $600 $500

Starting point costs for modules and other components (less the inverter) were

combined and calculated by subtracting inverter costs from the total costs reported by

LBNL for crystalline and thin-film technologies. These costs are shown in Table 17.

Table 17. Starting Point Costs for Module Plus Other Components

(2008$/kW

DC

)

` Cost by System Size ($/kW

DC

)

5 kW

DC

25 kW

DC

250 kW

DC

Crystalline $7,500 $7,300 $6,700

Thin-film $7,800 $5,800 $6,200

Cost trends over time were then developed for modules and other components based

on input from PV stakeholders and ICF in-house data. Module and other costs (less the

inverter) were assumed to follow the same cost trend, which is shown in Figure 14.

28

0%

20%

40%

60%

80%

100%

2008 2010 2012 2014 2016 2018 2020 2022 2024 2026 2028 2030 2032 2034

Year

Cost Relative to 2008

Figure 14. Normalized Cost Trend for PV Modules and Other Components

(does not apply to inverter)

Inverter costs presented somewhat of a dilemma. The technical performance of

inverters is evolving (e.g., development of microinverters), but there is mixed

information on whether inverter costs are declining or remaining steady. Some PV

stakeholders suggested that inverter costs are remaining steady, although price

declines have occurred in recent months.

8

ICF weighed the limited information

available for inverter costs, and chose to forecast inverter costs as remaining

unchanged in future years (same costs for crystalline and thin-film technologies). It is

expected that inverter performance features will continue to advance, but for forecasting

purposes ICF assumed that manufacturers will hold inverter prices relatively constant as

inverter performance improves (i.e., inverter value will increase, but prices will remain

steady).

An example of how the forecast costs for modules, inverters, and other components

changes over time is shown in Figure 15. This figure corresponds to a 5 kW

DC

crystalline PV system. As indicated, costs start at $8,200/kW

DC

($700 inverter plus

$7,500 for module and other components) in 2008, with inverters accounting for 9% of

the installed cost. Inverters remain flat over the forecast horizon, while module and

8

Solarbuzz provides an index of monthly inverter and PV module costs

(http://www.solarbuzz.com/Inverterprices.htm

).

29

other components decline. By 2035, the total installed cost is forecast to decline to

$4,000/kW

DC

with inverters accounting for 18% of the total installed cost. Similar

behavior is forecast for thin film technologies and larger sizes (25 kW

DC

and 250 kW

DC

).

Inverter

Module & Other

Components

0

1,000

2,000

3,000

4,000

5,000

6,000

7,000

8,000

9,000

2008 2010 2012 2014 2016 2018 2020 2022 2024 2026 2028 2030 2032 2034

Year

Cost (2008$/kW)

Figure 15. Cost Projection for 5 kW

DC

Crystalline System

5.2.2 Installed Capital Costs

Using the methodology described in the previous section, installed capital cost forecasts

were developed for crystalline and thin-film technologies. Reference case cost

projections for three sizes (5, 25, and 250 kW

DC

) of crystalline technologies are shown

in Figure 16, and cost projections for the same three sizes of thin-film technologies are

shown in Figure 17. Unless noted otherwise, all costs are reported in 2008 dollars.

As indicated, installed capital costs for all three crystalline sizes start in the range of

$7,000 to slightly greater than $8,000/kW

DC

in 2008, and then decline to a range

between $3,500 and $4,000/kW

DC

in 2035. For thin film technologies, the 5 kW

DC

size

starts at approximately $8,500/kW

DC

in 2008 and declines to slightly above

$4,000/kW

DC

in 2035. The larger 25 and 250 kW

DC

sizes start near $6,500/kW

DC

in

2008, and decline to slightly above $3,000/kW

DC

in 2035.

30

0

1,000

2,000

3,000

4,000

5,000

6,000

7,000

8,000

9,000

2005 2010 2015 2020 2025 2030 2035

Year

Cost (2008$/kW)

5 kW

25 kW

250 kW

Figure 16. Recommended Crystalline Installed Costs, Reference Case

One unexpected result shown in Figure 17 is that costs for a 250 kW

DC

thin-film system

are forecast to be slightly higher than a 25 kW

DC

system. Based on economy of scale

considerations, one would expect costs for a 250 kW

DC

system to be lower than a 25

kW

DC

system. However, these forecasts are consistent with historical costs, which do

show an up turn in costs for large thin film PV systems. Historical PV costs are

discussed in Section 4.1, and this discussion includes an important note concerning

thin-film costs. As mentioned in Section 4.1, historical thin-film costs should be viewed

with caution because these costs are based on a small sample size. It would not be

surprising if future thin-film costs follow economy of scale considerations (i.e., costs

decline as capacities increase).

31

0

1,000

2,000

3,000

4,000

5,000

6,000

7,000

8,000

9,000

2005 2010 2015 2020 2025 2030 2035

Year

Cost (2008$/kW)

5 kW

25 kW

250 kW

Figure 17. Recommended Thin-film Installed Costs, Reference Case

Figure 18 offers a perspective of how the forecast PV costs correspond to residential

applications. In this figure, 5 kW

DC

crystalline and 5 kW

DC

thin-film costs are shown,

which are representative of the residential market. As indicated, costs start in the range

of $8,000 to $8,500/kW

DC

in 2008, and then decline to approximately $4,000/kW

DC

by

2035. More specifically, costs are approximately $7,100 (crystalline) and $7,300 (thin-

film) in 2010. These costs fall to approximately $4,000/kW

DC

(crystalline) and

$4,100/kW

DC

(thin-film) by 2035.

32

0

1,000

2,000

3,000

4,000

5,000

6,000

7,000

8,000

9,000

2000 2005 2010 2015 2020 2025 2030 2035

Year

Cost (2008$/kW)

Crystalline 5 kW

Thin-film 5 kW

Figure 18. Residential Installed Capital Costs, Reference Case

Figure 19 includes both historical residential PV installed costs along with

recommended residential costs. Historical costs have fluctuated, but the trend over the

next 5-10 years in recommended PV costs is generally consistent with historical cost

trends over the past decade. As the market matures, PV costs begin to stabilize and

decline at lower rates.

33

0

1,000

2,000

3,000

4,000

5,000

6,000

7,000

8,000

9,000

10,000

11,000

2000 2005 2010 2015 2020 2025 2030 2035

Year

Cost (2008$/kW)

Historical, < 10 kW

Crystalline, 5 kW

Thin-film, 5 kW

Figure 19. Historical and Forecast Residential Capital Costs

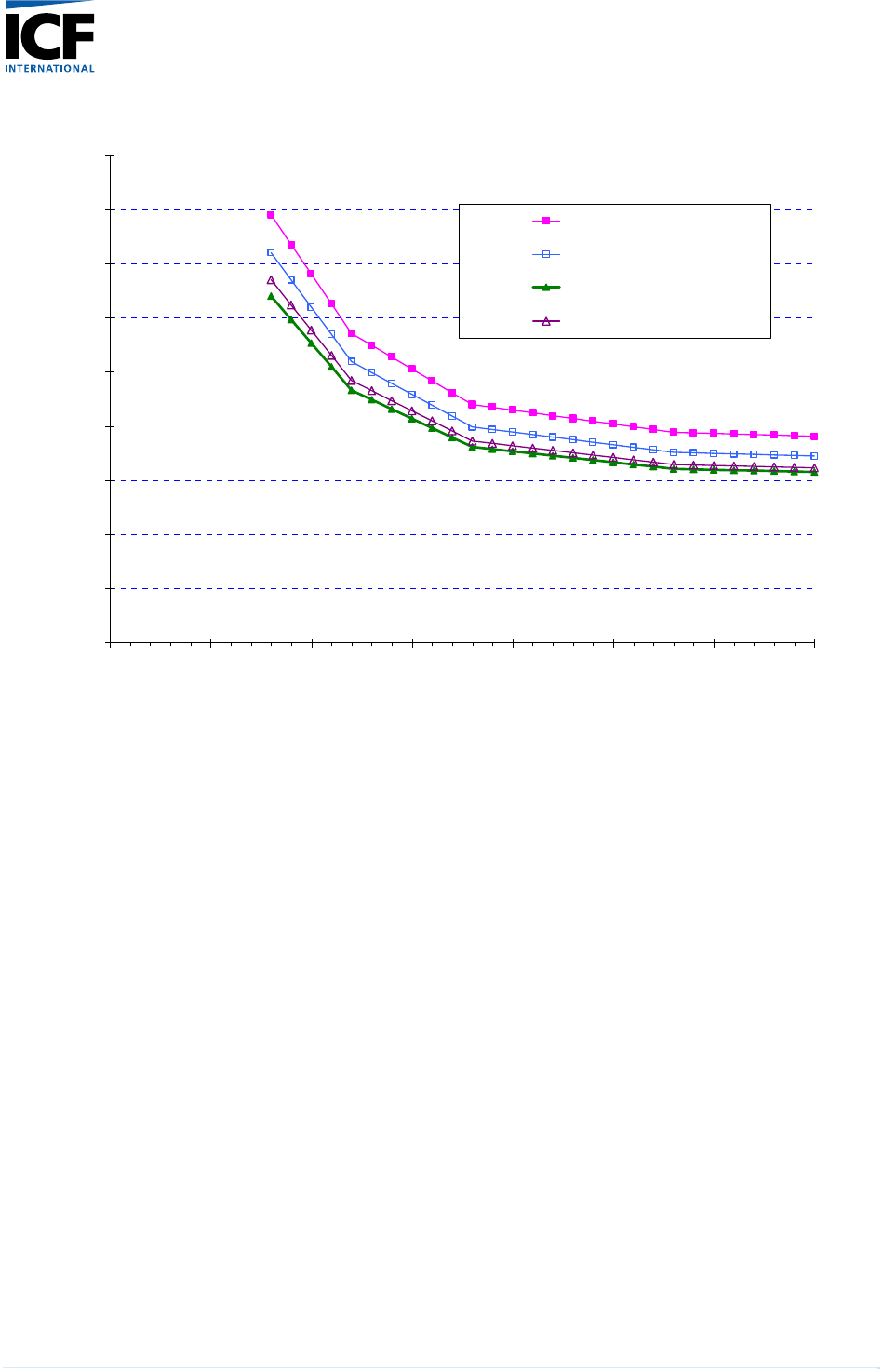

Recommended commercial capital costs are shown in Figure 20. This figure includes

recommended forecast values for four technologies (crystalline 25 kW

DC

, crystalline 250

kW

DC

, thin-film 25 kW

DC

, and thin-film 250 kW

DC

). As indicated, installed costs for

commercial PV installations range from approximately $6,500 to $8,000/kW

DC

in 2008,

and then decline to a range between $3,000 and $4,000/kW

DC

in 2035. More

specifically, commercial costs in 2010 are approximately $5,500/kW

DC

(thin-film,

25kW

DC

), $5,800/kW

DC

(thin-film, 250 kW

DC

), $6,200/kW

DC

(crystalline, 250 kW

DC

), and

$6,800 (crystalline, 25 kW

DC

). In 2035, the costs are approximately $3,200/kW

DC

(thin-

film, 25 kW

DC

and 250 kW

DC

), $3,500/kW

DC

(crystalline, 250 kW

DC

), and $3,800/kW

DC

(crystalline, 25 kW

DC

)

For perspective, historical and forecast trends are shown in Figure 21. Similar to the

residential results, historical cost trends have fluctuated, but the recommended cost

trends over the next 5-10 years are generally consistent with historical trends. Similar

to residential prices, the commercial prices begin to stabilize as the market matures.

34

0

1,000

2,000

3,000

4,000

5,000

6,000

7,000

8,000

9,000

2000 2005 2010 2015 2020 2025 2030 2035

Year

Cost (2008$/kW)

Crystalline, 25 kW

Crystallline, 250 kW

Thin-film, 25 kW

Thin-film, 250 kW

Figure 20. Commercial Installed Capital Costs, Reference Case

35

0

1,000

2,000

3,000

4,000

5,000

6,000

7,000

8,000

9,000

10,000

2000 2005 2010 2015 2020 2025 2030 2035

Year

Cost (2008$/kW)

Crystalline, 25 kW

Crystalline 250 kW

Thin-film, 25 kW

Thin-film, 250 kW

Historical, >10 kW

Figure 21. Historical and Forecast Commercial Capital Costs

The forecast of installed capital costs presented in this report was developed based on

opinions from PV stakeholders and other data sources concerning how costs may

change over the next couple decades. The forecast was not developed in conjunction

with a detailed demand forecast. While demand was not formerly considered, it is

interesting to consider how the installed capital costs projected in this report might be

correlated with a demand forecast.