MEDCOM Pam 40-13

DEPARTMENT OF THE ARMY

HEADQUARTERS, UNITED STATES ARMY MEDICAL COMMAND

2050 Worth Road

Fort Sam Houston, Texas 78234-6000

MEDCOM Pamphlet 13 February 2006

No. 40-13

Medical Services

U.S. ARMY VETERINARY COMMAND GUIDELINES AND PROCEDURES

TABLE OF CONTENTS

PARAGRAPH PAGE

CHAPTER 1. GENERAL INFORMATION

HISTORY ....................................................................................... 1-1 5

PURPOSE...................................................................................... 1-2 5

REFERENCES............................................................................... 1-3 5

EXPLANATION OF ABBREVIATIONS AND TERMS .................... 1-4 5

APPLICABILITY............................................................................. 1-5 5

CHAPTER 2. MANAGEMENT CONTROL PROCESS AND

ORGANIZATIONAL INSPECTION PROGRAM REQUIREMENTS

INTRODUCTION............................................................................ 2-1 6

INSPECTIONS............................................................................... 2-2 6

PROCEDURES.............................................................................. 2-3 8

CHAPTER 3. INSTALLATION SUPPORT PLAN PROGRAM

INTRODUCTION............................................................................ 3-1 9

IMPLEMENTATION OF THE ISP PROGRAM............................... 3-2 9

ISP DATABASE CONTACT REPORT ESTABLISHMENT ............ 3-3 15

CUSTOMER VISIT REPORTS (CVRs).......................................... 3-4 16

SUBSISTENCE INSPECTION REPORTS (SIRs).......................... 3-5 18

ISP DATABASE REVIEW .............................................................. 3-6 21

MCP/OIP INTEGRATION............................................................... 3-7 21

CHAPTER 4. SUBSISTENCE RECALLS

INTRODUCTION............................................................................ 4-1 46

PROCEDURES FOR DETERMINING IF A FOOD RECALL

ACTION IS REQUIRED ............................................................. 4-2 46

FOOD OR NONPRESCRIPTION DRUGS DIRECTLY ASSOCIATED

WITH A MEDICALLY VERIFIED PHYSICAL ILLNESS OR

INJURY ...................................................................................... 4-3 47

MEDCOM Pam 40-13

2

PARAGRAPH PAGE

DOD FOOD AND DRUG LABORATORY (FADL) RESPONSE..... 4-4 47

DEVELOPMENT OF LOCAL SOPs REGARDING ALFOODACTS.4-5 48

CHAPTER 5. INSPECTION OF PERISHABLE FOODS EXPOSED

TO REFRIGERATION FAILURE

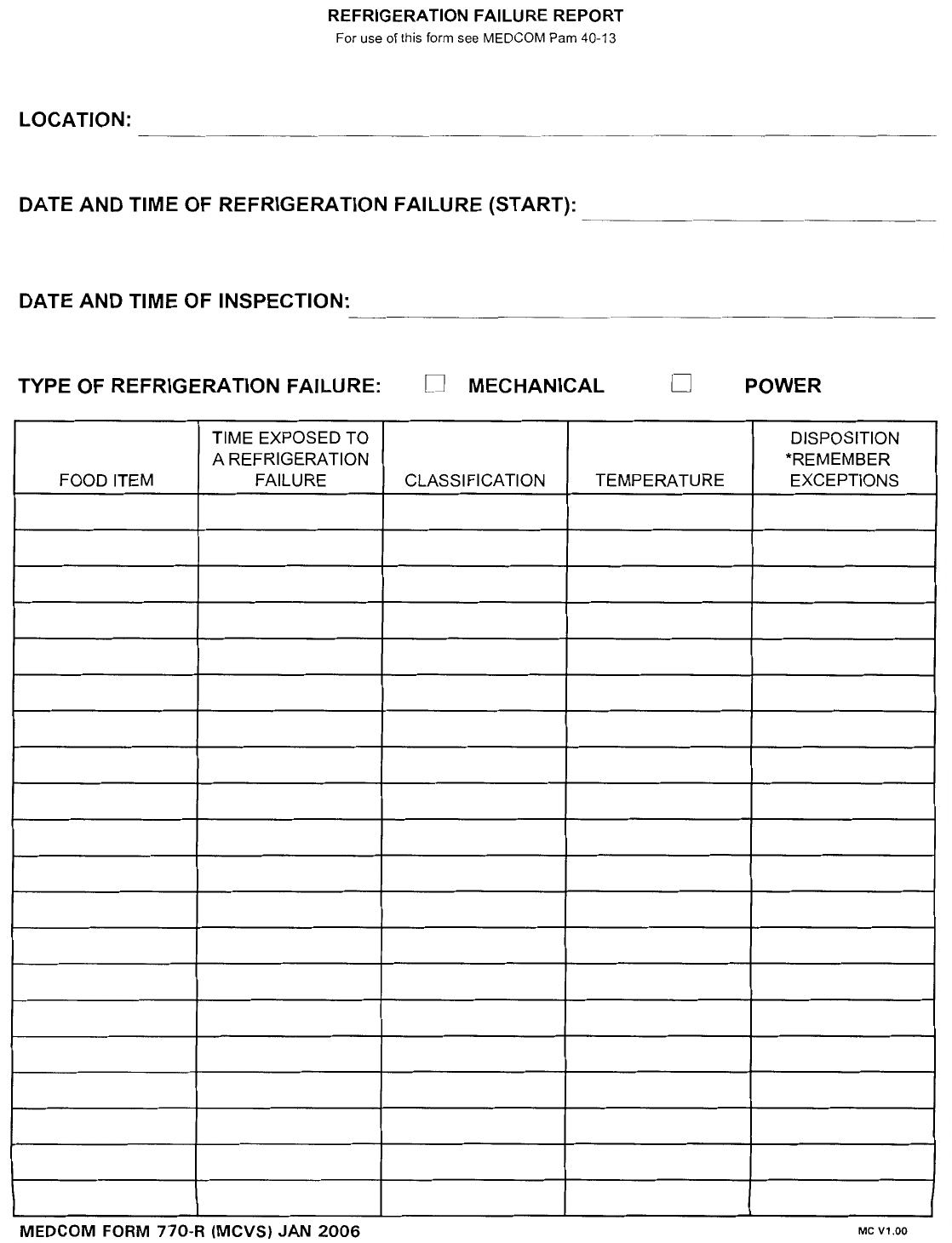

INTRODUCTION............................................................................ 5-1 49

GUIDELINES ................................................................................. 5-2 49

CLASSIFICATIONS OF FOODS BASED ON MICROBIAL

RISKS ........................................................................................ 5-3 59

CHAPTER 6. OPERATIONAL RATION PROGRAMS

INTRODUCTION............................................................................ 6-1 61

GUIDELINES FOR MEALS, READY TO EAT ASSEMBLY

PLANTS ...................................................................................... 6-2 61

GUIDELINES FOR DEPOT ASSEMBLY OPERATIONS............... 6-3 63

GUIDELINES FOR COMMERCIAL ASSEMBLY OPERATIONS

AT UGR-A ASSEMBLY PLANTS................................................ 6-4 64

GUIDELINES FOR COMMERCIAL ASSEMBLY OF

SURVIVAL-TYPE RATIONS AND THE HEALTH AND

COMFORT PACK ....................................................................... 6-5 65

GUIDELINES FOR INSTALLATION LEVEL INSPECTIONS ......... 6-6 65

LABORATORY ANALYSIS OF OPERATIONAL RATIONS........... 6-7 67

RECORDING AND REPORTING OF OPERATIONAL RATION

INSPECTIONS............................................................................... 6-8 67

CHAPTER 7. RECEIPT INSPECTIONS

INTRODUCTION............................................................................ 7-1 69

GENERAL RECEIPT INSPECTION PROCEDURES..................... 7-2 69

SPECIFIC RECEIPT INSPECTION SAMPLING TABLES FOR

RED MEATS, SHELL EGGS, FRESH FRUIT AND

VEGETABLES, SEMI-PERISHABLES AND PERISHABLES ..... 7-3 69

RECEIPT INSPECTION RESULT REPORTING

PROCEDURES........................................................................... 7-4 77

RISK ASSESSMENT FACTORS AND POTENTIAL RISKS .......... 7-5 77

CHAPTER 8. OCONUS FRESH FRUIT AND VEGETABLE

CONTAINER/AIRLIFT INSPECTIONS

INTRODUCTION............................................................................ 8-1 78

GENERAL ORIGIN INSPECTION PROCEDURES ....................... 8-2 78

GENERAL DESTINATION INSPECTION PROCEDURES............ 8-3 78

INSTRUCTIONS FOR COMPLETING OCONUS FF&V

CONTAINER/AIRLIFT INSPECTION SUPPORT REPORT........ 8-4 80

MEDCOM Pam 40-13

3

PARAGRAPH PAGE

CHAPTER 9. INSTALLATION FOOD SAMPLING PROGRAMS

INTRODUCTION............................................................................ 9-1 90

PROCEDURES.............................................................................. 9-2 90

CHAPTER 10. SALVAGE/DISTRESSED FOODS AT

GOVERNMENT RETAIL AND STORAGE FACILITIES

INTRODUCTION.......................................................................... 10-1 94

PROCEDURES............................................................................ 10-2 94

GUIDELINES ............................................................................... 10-3 95

CHAPTER 11. RAPID TESTING METHODS FOR

FOOD CONTACT SURFACES

INTRODUCTION.......................................................................... 11-1 96

GENERAL INFORMATION.......................................................... 11-2 96

PROCEDURES............................................................................ 11-3 97

PROGRAM GUIDANCE............................................................... 11-4 99

CHAPTER 12. FOOD INSPECTION EQUIPMENT

INTRODUCTION.......................................................................... 12-1 100

GENERAL FOOD INSPECTION EQUIPMENT............................ 12-2 100

SPECIALIZED FOOD INSPECTION EQUIPIMENT..................... 12-3 101

CHAPTER 13. MILITARY SANITARY INSPECTION PROGRAM

INTRODUCTION.......................................................................... 13-1 102

PROCEDURES............................................................................ 13-2 102

CHAPTER 14. SECURITY PROGRAMS

INTRODUCTION.......................................................................... 14-1 103

ANTITERRORISM........................................................................ 14-2 103

SUSPECTED INCIDENTS OF INTENTIONAL

CONTAMINATION ................................................................... 14-3 105

OPERATIONS SECURITY........................................................... 14-4 106

CHAPTER 15. PREDEPLOYMENT FOOD RISK

ASSESSMENTS IN THEATER OPERATIONS

INTRODUCTION.......................................................................... 15-1 113

RISKS ASSOCIATED WITH OCONUS PROCUREMENT........... 15-2 113

GENERAL GUIDANCE AND INFORMATION.............................. 15-3 113

COMMUNICATING FOOD RISKS............................................... 15-4 114

MEDCOM Pam 40-13

4

PARAGRAPH PAGE

CHAPTER 16. LABORATORY SAMPLE SUBMISSION GUIDANCE

INTRODUCTION.......................................................................... 16-1 117

PROCEDURES............................................................................ 16-2 117

CHAPTER 17. SUBJECT MATTER TRAINER PROGRAM

INTRODUCTION.......................................................................... 17-1 124

PROCEDURES............................................................................ 17-2 124

CHAPTER 18. SHIPRIDER PROGRAM

INTRODUCTION.......................................................................... 18-1 125

GUIDELINES ............................................................................... 18-2 125

CHAPTER 19. AUDITOR CERTIFICATION PROGRAM

INTRODUCTION.......................................................................... 19-1 128

PROCEDURES............................................................................ 19-2 128

APPENDIX A (REFERENCES)............................................................. 131

APPENDIX B (SAMPLES OF CUSTOMER VISIT REPORTS/

SUBSISTENCE INSPECTION REPORTS)...................................... 134

GLOSSARY .......................................................................................... 152

DA/DD/MEDCOM FORMS.................................................................... 160

MEDCOM Pam 40-13

5

CHAPTER 1

GENERAL INFORMATION

1-1. HISTORY. This is the first printing of this publication.

1-2. PURPOSE. This pamphlet supplements the policies and procedures that are

contained in MEDCOM Regulation 40-28, U.S. Army Veterinary Command Policies and

Procedures.

1-3. REFERENCES. References are listed in appendix A.

1-4. EXPLANATION OF ABBREVIATIONS AND TERMS. Abbreviations and special

terms used in this publication are explained in the glossary.

1-5. APPLICABILITY. This pamphlet applies to Headquarters, U.S. Army Veterinary

Command (HQ VETCOM) and its subordinate commands.

MEDCOM Pam 40-13

6

CHAPTER 2

MANAGEMENT CONTROL PROCESS AND ORGANIZATIONAL

INSPECTION PROGRAM REQUIREMENTS

2-1. INTRODUCTION.

a. The purpose of the Management Control Process (MCP) is to reinforce the

accountability of Army commanders and managers for establishing and maintaining

effective management controls and to provide them with greater flexibility in their

evaluation of these controls. All commanders and managers have an inherent

responsibility to establish and maintain effective controls, assess areas of risk, identify

and correct weaknesses in those controls, and keep their superiors informed. In this

respect, the Integrity Act and OMB Circular A-123 codify this inherent responsibility.

Army Regulation 11-2, Management Control, and the MEDCOM MCP Handbook,

currently found at the website http://www.cs.amedd.army.mil/ameddir/TabD.doc,

provide detailed information on the MCP.

b. The purpose of the Organizational Inspection Program (OIP) is to manage all

inspections within the command. It is a comprehensive, written plan that addresses all

inspections and audits scheduled by outside agencies. The purpose of the OIP is to

coordinate inspections and audits into a single, cohesive program focused on command

objectives. Depending upon the level of command, the OIP will comprise command

inspections, staff inspections, staff assistance visits, and external inspections. An

effective OIP allows a commander to use these inspections to identify, correct, and

prevent reoccurrence of problems within the command. Commanders should also use

the OIP to complement and reinforce other sources of evaluation information when

determining or assessing readiness. Army Regulation 1-201, para 3-2, provides

detailed information on the organizational inspection program.

c. Commanders should schedule MCP and OIP inspections simultaneously in order

to limit distraction from mission accomplishment. This chapter applies to both OIP and

MCP inspections. The reporting templates posted to the VETCOM Library database in

Lotus Notes fulfill both requirements.

2-2. INSPECTIONS.

a. HQ VETCOM will inspect each Regional Veterinary Command (RVC); the

Department of Defense Military Working Dog Veterinary Service (DODMWDVS); and

the Food and Diagnostic Laboratory (FADL) every 2 years using the applicable checklist

posted in the VETCOM Library database in Lotus Notes. Results of this inspection will

be retained at VETCOM HQ; copies will be given to the Functional Unit Managers.

MEDCOM Pam 40-13

7

b. Each RVC will inspect its subordinate District Veterinary Commands (DVCs)

annually. An example of a DVC checklist is provided in the VETCOM Library database

in Lotus Notes. Functional Unit Managers should modify the checklist to adjust to the

local circumstance within their respective areas of responsibility. Revised checklists will

be in full compliance with the appropriate regulations, VETCOM mission guidance, and

with the Assessable Unit Manager’s intent. Copies of completed inspection checklists

will be retained at the RVC with copies forwarded to the DVC. Checklists are to be

forwarded to VETCOM HQ only when a material weakness (es) is identified. Functional

Unit Managers will submit an MCP Report, using the template posted on the VETCOM

Library in the Lotus Notes database, every year on 1 Jul to HQ VETCOM (ATTN:

Management Control Administrator). The reporting period consists of the preceding

year ending on 30 June XXXX. For example, 1 July 2003 to 30 June 2004 will

constitute a year and is reportable on the 1 July 2004 report.

c. Each DVC will inspect each branch within their respective areas of responsibility

annually. Results will be recorded on an RVC approved checklist. Examples are

provided at the end of this chapter. Reports will be maintained at the DVC and branch

level. The DVC will conduct site visits as required and after discussing site status with

respective branch leadership. Site visit reports, generated by the branch after each site

visit, will be reviewed in order to make visit determinations as appropriate.

d. Branch officers in charge (OICs) and noncommissioned officers in charge

(NCOICs) will inspect each site within their respective area at a frequency determined

by the Branch leadership in coordination with the District Veterinary Commander.

Appropriate inspection checklist will be determined by each District Commander. The

checklist posted in the VETCOM library database in Lotus Notes may be utilized or

modified accordingly. Trip reports will be generated no later than 7 duty days after each

site visit and distributed to each site and district for review, corrective action, and

retention in files.

e. Inspections should identify both shortcomings and strengths. A written summary

will be contained in the checklist to include--

(1) Material Weaknesses--as defined in AR 11-2. MEDCOM Regulation 40-28,

2-3c helps determine if the weakness is material.

(2) Findings--a deficiency in unit operations that does not meet the standard of a

regulation or policy.

(3) Observations--an area, based on the judgment of the inspecting auditor that

could be improved upon.

(4) Commendable--a judgment by the inspecting auditor describing superior

performance of an operation or process.

MEDCOM Pam 40-13

8

(5) Overall Summary--mandatory summary giving details of the overall

inspection results.

f. Material weaknesses will be reported as a Significant Incident Report, completed

in accordance with applicable VETCOM policy.

g. Annotations on the checklist may be handwritten or typed. Copies of completed

reports will be maintained at all applicable levels for 5 years, and then destroyed.

Subordinate offices will report completion date of the corrective action, or a progress

reported that includes anticipated completion date, to the auditing headquarters within

30 days of the inspection.

2-3. PROCEDURES.

a. Corrective action is required for all findings and/or material weaknesses. The

corrective action requirement will be clearly stated, a suspense date will be given, and

the inspecting level of command will track the requirement until the subordinate

responds in writing that the deficiency has been corrected.

b. HQ VETCOM will establish a 5-year MCP/OIP Inspection Plan that will be

updated every October (see example in the VETCOM Library). Regional commanders

will forward, as part of their annual report, an inspection plan for their subordinate units

that is expressed in months and covers a 2-year period.

c. Commanders at all levels are encouraged to invite outside agencies with special

expertise to inspect areas of particular risk or interest within their command.

d. Functional Unit Managers and Administrators will complete annual MCP training

as supplied by the Management Control Administrator.

MEDCOM Pam 40-13

9

CHAPTER 3

INSTALLATION SUPPORT PLAN PROGRAM

3-1. INTRODUCTION.

a. This chapter establishes procedures for implementation, administration, and

oversight of the Installation Support Plan (ISP) Program. The ISP is designed to assist

the Installation Veterinary Officer-In-Charge (OIC) in making risk-based assessments of

veterinary public health requirements and to wisely match existing resources against the

entire spectrum of food safety, food security, animal programs, and customer needs for

a given installation.

b. The ISP serves as the cornerstone for the organizational mission. The three

primary pillars of support consist of food safety and quality assurance, food security,

and animal programs.

3-2. IMPLEMENTATION OF THE ISP PROGRAM.

a. Assessment Process.

(1) The Installation Veterinary OIC in consultation with the District Commander

will review the following information and other useful resources in order to assess the

need for veterinary service support:

(a) Existing programs.

(b) Veterinary services personnel assigned to the installation, that is,

Veterinary Corps Officers, Warrant Officers, civilians, 91Rs and 91Ts.

(c) Installation and tenant activity personnel, that is, Dining Facility (DFAC)

Management; Installation Food Service Advisors; Defense Commissary Agency

(DeCA); Morale, Welfare, and Recreation (MWR); Non-appropriated fund management;

Exchange Service Management, etc.

(d) Pertinent military treatment facility (MTF) personnel, that is, Public Health

Officers, Environmental Safety Personnel, Occupational Health, etc. to discuss Rabies

Programs, Bite Reports, and other existing programs that are interrelated with the

veterinary services provided to the installation.

(e) A face-to-face meeting is required with Preventive Medicine (PM)

representatives to discuss veterinary installation support and identify risk areas due to

gaps in oversight. VETCOM and PM capabilities should be strengthened through

MEDCOM Pam 40-13

10

simplified communication, joint inspections, joint training, and by joining mission

capabilities as much as possible. Such coordination shall not convey an assumption of

responsibilities or authority, but rather an effort to strengthen both activities. The main

focus should be on pooling efforts and preventing a duplication of efforts. Foodborne

illness reporting procedures and notification systems will also be discussed in order to

ensure that Veterinary Service personnel are aware of and comply with the procedures

in place.

b. ISP Design Strategy.

(1) After assembling a list of potential veterinary service support requirements as

detailed above, the Installation Veterinary OIC assigns risk levels based upon the

potential consequences of not having veterinary service involvement in each area and

the likelihood of the occurrence of risks. Variables to consider in the calculation include

inherent risk associated with the mission facet, severity of impact, population affected,

historic frequency of occurrence, operational military impact, and conformity with

VETCOM’s Mission Essential Task List (METL) and mission priorities. Costs

associated with the need (that is, manpower, equipment, funding) are not considered

during this stage. Risk level defaults will be set and verified in the Lotus Notes ISP

database. Levels will be reviewed and adjusted as often as required and as a result of

each facility’s subsequent performance.

(2) The Installation Veterinary OIC will draft the ISP (See figure 3.1 at the end of

this chapter for examples of completed ISP documents). Once risk levels are assessed,

variables to consider in the creation of the ISP include: availability of personnel and

resources; expected degree of risk mitigation; time and distance constraints; availability

of alternate civilian or military sources of services; surrounding public health

infrastructure; civilian or military political considerations; and environmental decision

making. If resources are not available to fulfill a requirement, a request is forwarded up

the chain of command proposing a reallocation of resources. The District Commander

will review, make suggestions, and make the final approval of the plan upon finalization.

(3) Food service sanitation programs are particularly important in this process.

When PM assets are insufficient to accomplish their respective mission, and when the

District Commander agrees that the requirement for food service sanitation oversight

outweighs other District priorities, the DVC and Command Medical Authority can make

a written local agreement for mission transfer. Notification of this change, and a report

of how training and mission will be accomplished to standard, will be sent forward

through the Regional Veterinary Command to HQ, VETCOM.

c. Assessment of Risk Levels.

(1) Default frequencies are established in the Lotus Notes database for all food

safety inspections. The risk level and programmed default frequencies are defined as

follows:

MEDCOM Pam 40-13

11

(a) High Risk Level – A food establishment operation that through the type

of food prepared and served, population served, previous inspection history or

operational risks present an ABOVE AVERAGE risk for potential foodborne illness. The

program default frequency is set for weekly support.

(b) Moderate Risk Level – A food establishment operation that through the

type of food prepared and served, population served, previous inspection history or

operational risks present an AVERAGE risk for potential foodborne illness. The

program default frequency is set for monthly support.

(c) Low Risk Level – A food establishment operation that through the type of

food prepared and served, population served, previous inspection history or operational

risks presents a MINIMUM risk for potential foodborne illness. Program default

frequency is set for quarterly support.

(2) During staff and/or customer visits the inspector will reassess the risk level of

the facility based upon results of subsequent visits and discussions with facility

managers. Veterinary, Warrant Officers and Branch NCOICs can change default

frequencies in the database system as deemed appropriate. The computer program will

automatically reflect changes to default frequencies. This is a management tool for the

District and Regional Commanders and allows them to carry out their respective

program oversight responsibilities.

(3) Use of approved source lists will be enforced when meeting with agencies/

activities that procure food locally. Locally generated purchase agreements/contracts

will be reviewed for quality assurance provisions. If food safety and quality assurance

provisions are not found, recommendation for inclusion will be made, that is, age upon

delivery, temperature requirements, etc. An agreement will be made regarding location

where support will be provided, such as having delivery conveyances stop at a central

inspection point or inspecting delivery at first receiving facility.

(4) Hazardous food recall inspections. Physical checks at all installation

locations are required where recalled items are potentially stocked. If inspection

personnel are certain that the recalled items are not carried at particular activities,

telephone checks are authorized as directed in local standing operating procedure

(SOP). In order to gain awareness of merchandise stocking practices and trends, it is

critical that personnel verify items received through review of contracts, receiving

documents, and regular site visits. All telephone checks require a follow-up physical

inspection of each particular site during the next regularly scheduled visit. However, the

Branch NCOIC can authorize telephone checks without follow-up at predetermined

locations outside of practical driving distances. All Branch level NCOICs will enter recall

results into the Lotus Notes ISP database.

MEDCOM Pam 40-13

12

d. DeCA Support.

(1) Verification of meat market and deli cleanup operations. This verification

shall be performed in conjunction with the DeCA Quality Assurance Element (QAE) and

contract cleaning supervisor if they are available. It is accomplished during and after

the meat market and deli are cleaned and sanitized prior to the contract cleaning team’s

departure. It is normally a visual inspection but may include swabbing at the unit’s

discretion. This may require that inspection personnel verify cleaning and sanitizing

after the store closes and before the markets start work. This task will be performed not

less than three times per week initially. Frequency can be reduced based upon

continued satisfactory results per the DVC Commander.

(2) The DVC Commander or their representative will notify the DeCA Region if

continual contractual performance problems occur.

(3) Upon request by the DeCA Store Manager/Director, a senior person on the

installation veterinary staff will serve as a consultant when the commissary presents

unresolved pest management and waste disposal issues/problems to the Installation

Department of Public Works or equivalent office for rapid resolution.

e. Exchange Service/MWR/Hospital Feeding. Support will be given to all exchange

and MWR food facilities and especially hospital dining activities. This includes all snack

bars located in hospitals. Increased emphasis will be placed on food security and on

assisting with/training receiving personnel on performing receipt inspections. Hands-on

food inspections must be performed while at these sites in accordance with command

directed documents and/or SOPs. Highest priority shall be given to deliveries at

hospital dining facilities.

f. Troop Feeding/Prime Vendor. The only required type of inspection under this

program is the surveillance inspection. Inspector presence will be increased at the

dining facilities and DOD schools and activities in order to ensure that receiving

personnel are properly trained on performance of receipt inspections. Visits will be

focused on the inspection of food products in storage, not on performing sanitary

inspections. Latent defects must be identified and reported through the prime vendor

program (see VETCOM HBK 40-2 for detailed guidance). Defects found as a result of

age or storage conditions are reported through normal ISP channels. If the condition of

food items in storage is deteriorated, this may lead to an inspection of the storage room

(i.e., thawed items, moldy items, etc.). Inspections of food preparation areas will not be

performed unless an agreement exists with the local preventive medicine/environmental

health unit. Food inspectors’ inspection knowledge in “market ready” items (fluid dairy,

bread, produce, etc.) will be continuously developed through documented training.

Quarterly visits with prime vendor customers/ representatives will be made in order to

discuss/resolve problems and issues. It is imperative that the NCOIC, Warrant Officer,

or Installation Veterinary OIC attend all scheduled installation menu board meetings.

MEDCOM Pam 40-13

13

g. Installation Support. With coordination and agreement with the Provost Marshal

and Installation Commander, develop program to increase food security/defense

capabilities and awareness installation wide, to include commercial vehicle entry points.

Random cursory inspections of vehicles, containing food or water, will be performed at a

minimum of once/week. These cursory inspections should determine the following:

approved sources, inspect for tampering, inspect the bill of lading, evaluation if vehicle

is properly sealed.

h. Point of Contact Confirmation. Points of contact and expected workloads will be

confirmed and updated on a quarterly basis with the personnel identified in a.(1)(c) of

this chapter. Face-to-face meetings will be made when personnel changes occur at the

Veterinary OIC/NCOIC level, or key procurement activity personnel are made.

i. Presenting Approved ISP to Lead Agency Representatives:

(1) The Installation Veterinary OIC will present the ISP to senior installation

activity officials no less than annually and/or when significant mission, personnel,

operational conditions, or workload changes take place. Lead agency representatives

include (list is not all-inclusive):

(a) Installation Commander, or representative

(b) DeCA Store Director/Manager.

(c) Exchange Food Service manager or General Manager.

(d) MWR Chief, Food Manager, Financial Officer, or Quality of Life (QOL)

Chief.

(e) Installation Food Service Advisor/Food Service Manager/Troop Issue

Subsistence Officer (TISO).

(f) Provost Marshal.

(g) Emergency Room/PM Department Chief/PM Radiation Protection Officer

(h) Housing Manager.

(i) Operations Officer (G3) for maneuver command.

(j) Wildlife/Pest Management/Post Engineers.

(k) Quartermaster Corps during “field exercises.”

MEDCOM Pam 40-13

14

(2) The Installation Veterinary OIC and NCOIC will review and adjust the ISP no

less than annually and then meet face-to-face with the senior representative of each

lead activity to communicate the following areas:

(a) After action report of past year’s veterinary public health mission

performance to include the benefits of services and consequences of requirements that

are not met.

(b) Review the needs assessment.

(c) List the unmet needs and the reasons/impact of not providing the service.

(d) Worksite locations, hours, personnel assigned, and expected workload

performance.

(e) Anticipated events by Veterinary Service (VS) personnel that significantly

impact workload (training events, troop rotations, personnel changes, special or

seasonal events).

(f) Resources provided by VS and receiving activity, that is, vehicles, local

area network (LAN) access.

(g) Potential joint training topics.

(h) Training frequency/schedule/oversight.

(i) Emergency preparedness.

(j) Reporting mechanisms and point of contact (POC) rosters.

(k) Overlap, under-lap, and coordination with PM or other affiliated agencies.

(l) Situations that may involve the Public Affairs Officer or civilian media.

(3) The District Commander and the assigned Installation Veterinary OIC should

meet with the Installation Commander, or their representative at least annually. During

this coordination meeting veterinary personnel will provide a copy of the ISP and will

brief the following topics:

(a) Structure and function of the ISP.

(b) The role of Veterinary Services in food safety and security and the need

for approved sources in all fixed and temporary installation food activities.

MEDCOM Pam 40-13

15

(c) The role of Veterinary Services in animal health and welfare on the

installation to include the care and use of government-owned and privately-owned

animals.

3-3. ISP DATABASE CONTACT REPORT ESTABLISHMENT.

a. Rules of use.

(1) Initiating the contact report:

(a) Can be initiated by the Installation VCO or other personnel IAW local

SOP.

(b) Must be initiated under the following conditions:

i. When a new HQ Agency is opened or established. This does not consist of

individual facilities or stores, but rather the HQ Office responsible for such facilities.

ii. At time of annual review/update.

iii. Any other time that a contract is made with the agency manager as

described above.

(2) Editing. Facility visit frequency can only be edited by either the Installation

Veterinary OIC or Branch NCOIC when deemed necessary and as a result of a facility

visit.

b. Command expectations.

(1) MEDCOM Reg 40-28 dictates minimum frequency for contacting each major

agency at installation level/installation commander.

(2) Local SOP will dictate facility frequency which is set on the database by

default, but can be manually changed by the NCOIC/OIC as deemed necessary.

(3) Review and update installation contact information at least annually or as

needed, i.e., change in agency manager or Installation Veterinary OIC.

(4) Assign correct risk level according to the criteria delineated in paragraph 3-

2b above.

(5) It is expected that multiple reports will be listed for each agency. This is

because a new contact report is generated at a minimum of once per year, as well as

resulting from any contacts made throughout the year.

c. Common errors to avoid.

MEDCOM Pam 40-13

16

(1) Frequencies listed on the contact report are not being followed.

(2) Incorrect frequency is listed for the facility.

(3) Update facilities when needed, i.e., after follow-up meetings.

(4) Editing the most recent contact report does not constitute an annual review.

3-4. CUSTOMER VISIT REPORTS (CVRs).

a. Rules of use.

(1) Completed every time a visit is made to a site agreed upon under the ISP. It

is highly possible that a CVR will be completed with no associated SIR. The types of

visit applicable are:

(a) Routine.

(b) Customer Request.

(c) Follow-up.

(d) ALFOODACT.

(e) Refrigeration Failures.

(f) Navy Ships/Subs.

(g) Vehicle entry control points.

(2) One CVR will be generated per facility per day visited. Only one CVR per

day is completed at commissary sites. Each inspector is listed on the single CVR.

Macro type information is listed.

(3) When an SIR is entered, it will automatically be reflected under the facility

CVR for that day. If a CVR is not entered on the same day that an SIR is entered, there

will be no CVR under which the SIR will be reflected. This is an auto command

performed by the database.

(4) Local Installation requirements may require other applicable documents to be

generated from a CVR.

(5) Sanitation Standards to use. These are listed so that inspectors have a

standard to reference for sanitation deficiencies found.

MEDCOM Pam 40-13

17

(a) MIL-STD 3006: military warehouses.

(b) TB MED 530: Army DFACs.

(c) Food Code: All others.

(d) NA: If type of visit does not require sanitation check.

(e) Other: Navy or Marine Corps documents.

b. Command expectations.

(1) ISP agreements with agency managers will drive the level of support given

during each visit. Sample sizes are driven by local SOPs. Regardless of minimum

sample sizes, inspectors should not be limited by sample size and are encouraged to

inspect more product than what is indicated in the sample size as appropriate. Do not

let sample sizes be limited by forms completion. The focus is on performing good,

comprehensive surveillance on a wide variety of line items/cases.

(2) Macro information. List what was performed in a broad, generalized sense

on the CVR. See the example of a completed CVR for guidance.

(3) Typical support expected:

(a) Retail shops: Walk through the sales floor at retail shops looking at code

dates, obvious damage, deterioration, approved source scans, refrigeration/ freezer

display temperatures. Visit all walk-in coolers and other food storage areas, noting any

food problems and/or general sanitation problems.

(b) MWR sites: Storage areas only, inspecting food in storage for obvious

defects. If sanitation deficiencies are found that may affect the food stored, annotate

the CVR and, and if severity dictates, notify PM. The level of sanitation cognizance may

be increased at sites that PM traditionally performs sanitary inspections on (i.e., clubs),

if local written agreements with PM exist.

(c) DFACs and land-based Navy galleys

: The expectation is that each dining

hall/galley should be visited at least weekly. Visit all storage areas and product staging

areas only, inspecting food for obvious defects. Defects must be categorized as latent

defects if they are caused by the producer or distributor. If the defects are caused by

the facility, they are categorized as a storage/handling defect. Be aware of imminent

health hazards that may be present. If sanitation deficiencies are found that may affect

the food stored, annotate the CVR and, and if severity dictates, notify PM. The level of

sanitation cognizance may be increased if local written agreements with PM exist.

MEDCOM Pam 40-13

18

(d) Commissary: IAW agreed upon support. CVRs are required daily.

Traditional support includes delivery inspections (all requiring SIRs); sanitary walk-

through inspections; surveillance inspections; etc.

c. Common errors to avoid.

(1) The most significant error to guard against is identifying problem areas, then

not listing and taking any further actions. If food problems or sanitation problems are

noted, inspectors must list on the CVR the actions they are taking in response to the

problem found. This might involve a change in risk category and/or frequency of visit.

The CVR cannot list problems without also detailing final disposition actions.

(2) The goal is not to perform "formal" sanitary inspections at each site. Those

type inspections are performed under other programs. Let the condition of the food lead

you to sanitation problems, not the other way around. For example, finding moldy

produce in a cooler may lead you to observe the walls, floors and ceilings of the

refrigeration unit. Observing items with heavy frost may lead you to review temperature

charts for the refrigeration units.

(3) Do not let sample sizes be limited by forms completion. Perform good

comprehensive surveillance on a wide variety of line items/cases.

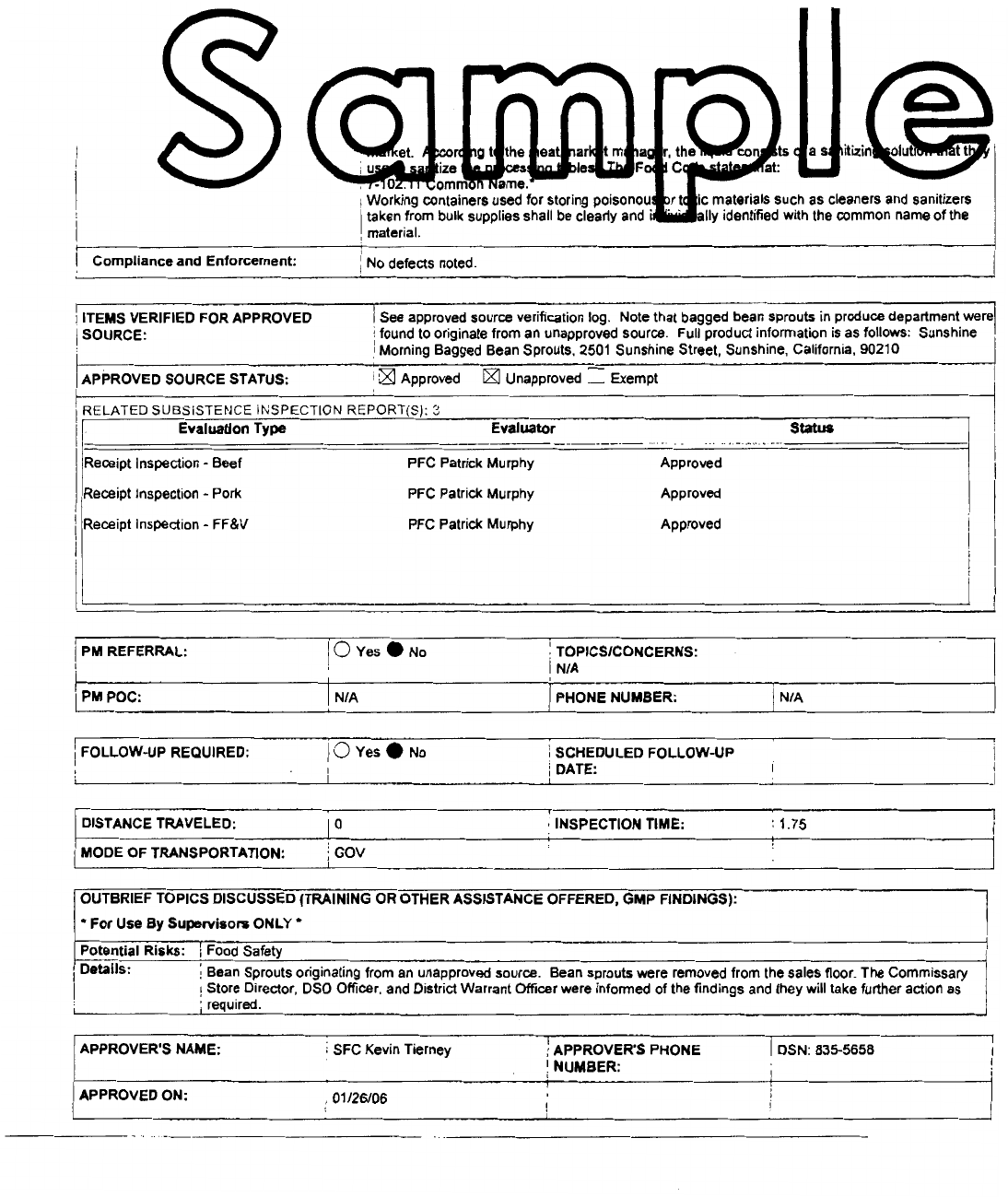

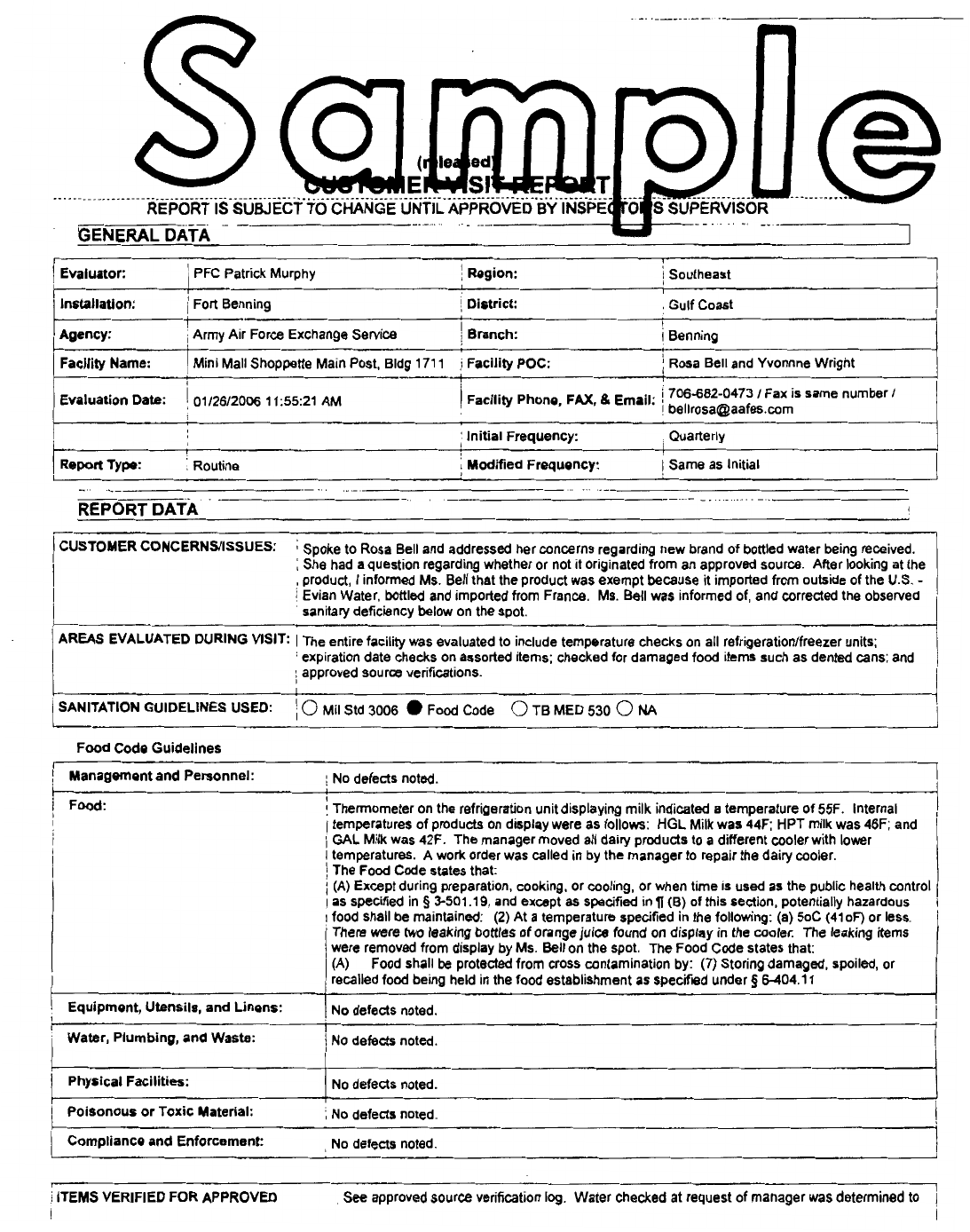

d. Examples of completed CVRs can be found in appendix B.

Commissary

Other Retail

MWR

DFAC/Troop Feeding

Ships

3-5. SUBSISTENCE INSPECTION REPORTS (SIRs).

a. Rules of use.

(1) An SIR must be generated for--

(a) A product defect/nonconformance is detected in conjunction with a visit to

a facility.

(b) Returned product inspection during which a DOPI was performed.

(c) For all receipt inspections performed during which a DOPI was performed

and at the minimum frequency required in accordance with local SOP and applicable

regulations.

MEDCOM Pam 40-13

19

(2) The four types of SIRs are--

(a) Receipt.

(b) Surveillance.

(c) Returned Product Inspection.

(d) Prime Vendor Surveillance.

(3) Receipt inspection reports are required for--

(a) Beef.

(b) Pork.

(c) FF&V.

(d) Other.

(4) Surveillance inspection reports require a complete, detailed listing of each

product that is inspected. This type of inspection is typically limited to government-

owned, non-retail products. The only exception to the retail product limitation is typically

at facilities located overseas. Surveillance inspections will be conducted and entered

into the ISP database in accordance with local SOP.

(5) Returned Product inspection reports are required when product(s) are

inspected due to a customer complaint.

(6) Prime Vendor Surveillance inspection reports will be generated when

detailed product evaluations are conducted. Nonconformances listing latent defects will

be forwarded through the chain of command to HQ VETCOM, via auto messaging.

b. Command expectations.

(1) ISP agreements with agency managers will drive the frequency of

inspections performed during each visit. Inspection frequencies and sample sizes are

driven by local SOPs.

(2) List inspection details in a manner that clearly communicates standards,

nonconformances and inspection results.

(3) Typical support expected:

MEDCOM Pam 40-13

20

(a) Commissaries. Receipt inspections should be conducted at a frequency

that is agreed upon in accordance with the ISP. An SIR will be completed for each

receipt inspection performed when destructive open package inspection is performed,

or upon finding nonconformances. Traditional support includes regular receipt

inspections of all food delivered to the commissary during support hours, with an

emphasis on high-dollar value or potentially hazardous foods.

(b) Dining Facilities and Galleys. Receipt inspections should be conducted at

a frequency that is agreed upon within the ISP. Equal emphasis should be placed on

inspections of both market ready (milk, bread, etc.) and prime vendor items.

(c) MWR/Club System. Receipt inspections should be conducted at a

frequency that is agreed upon with the installation representative in accordance with the

ISP.

(d) Exchange Retail Facilities. Receipt inspections should be conducted at a

frequency that is agreed upon with the installation representative in accordance with the

ISP.

c. Common errors to avoid.

(1) Inspectors must be clear on the specific product requirements when

conducting subsistence inspections. For example, specific requirements with respect to

product age upon delivery, temperature requirements, etc. must be known in order to

conduct an inspection to standard.

(2) Specific inspection results must be recorded on the SIR in detail. The CVR

will not be used in order to convey product inspection results, whenever a SIR is

required.

(3) Inspectors must report nonconformances to the accountable officer. When

accountable officers opt to accept products that may pose a potential wholesomeness

problem, the Veterinary OIC or Warrant will be notified immediately.

(4) Multiple contractors listed on one report. There should be one SIR per

contractor.

d. Examples of completed SIRs can be found in appendix B.

Receipt – Beef, FF&V, Pork, Other.

Surveillance.

Returned Product Inspection.

Prime Vendor Surveillance.

MEDCOM Pam 40-13

21

3-6. ISP DATABASE REVIEW.

a. The Branch Veterinary OIC and NCOIC will review respective section reports and

discuss them with each Section Veterinary OIC and NCOIC. Critical areas that must be

kept in mind while performing the reviews and discussions are as follows:

(1) The need to communicate food safety, security, and food quality issues at all

levels throughout the Region through the chain of command.

(2) Recommendation of possible changes in local procedures and frequencies

based upon inspection results. This will help the Branch to set goals and give direction

for any follow-up action such as additional site visits that are needed.

(3) Timely and accurate report completion and review.

b. It is highly recommended that database reviews and results be documented and

maintained for reference. The review information can be used to track inspections

trends and coordinate appropriate inspector training. Figure 3.2 at the end of this

chapter illustrates an example of how a Branch and a District level review can be

effectively captured.

3-7. MCP/OIP INTEGRATION.

a. MCP/OIP visits will strongly focus on the ISP Program. Items of interest shall

include:

(1) Is the written ISP current?

(2) Has the plan been communicated appropriately to senior installation

personnel?

(3) Do local SOPs contain details of how each agency will be supported?

(4) Is the agreed upon support performed?

(5) Does the support include receipt and surveillance inspections, sanitation,

food security recommendations, education, and training?

(6) Are significant actions reported as required and addressed in a timely

manner?

MEDCOM Pam 40-13

22

Figure 3.1 – Installation Support Plan Example

EXAMPLE ONLY – INDIVIDUAL ISPs WILL VARY WITH EACH INSTALLATIONS

MISSION REQUIREMENTS

DEPARTMENT OF THE ARMY

HEADQUARTERS, UNITED STATES ARMY VETERINARY COMMAND

2050 WORTH ROAD, SUITE 5

FORT SAM HOUSTON, TEXAS 78234-6005

(Use Appropriate Letterhead)

REPLY TO

ATTENTION OF

MCVS XX Date XXXX

MEMORANDUM FOR Commander, South Plains District Veterinary Command,

Fort Anywhere, XX 12345

SUBJECT: Installation Support Plan, Fort Sam Houston, TX 78234

1. Attached is the Installation Support Plan for Fort Sam Houston, TX, which defines

the level of veterinary food inspection support, agreed upon with the activities listed

below.

2. Activities Supported.

a. Troop Feeding.

(1) Dining Facilities.

(2) TISA Warehouse/UBLs.

b. Defense Commissary Agency (DeCA).

c. Exchange Services.

(1) Shoppettes/Food Courts/Food concessionaires.

(2) Retail Outlets (PX, retail stores, BX Marts, etc.).

(3) Other Activities (Bowling Center, bookstore, gas stations, etc.).

d. Morale, Welfare, and Recreation (MWR).

MEDCOM Pam 40-13

23

(1) Clubs.

(2) Other Activities (Golf Course, Rod & Gun, etc.).

e. General Installation/Area Support.

(1) ABC Reserve Center.

(2) Coast Guard Supply Center.

(3) Ship/Sub Support.

(4) Installation Level Issues.

(a) Food Security/Vulnerability Assessments/Food Vehicle check points.

(b) Special Events Support (Armed Forces Day, Fests, etc.).

(c) Operational Exercise/Training Support ("Golden Saber"; survival training

field activities; etc.).

(d) Ship Rider Program.

(e) Food inspection support to schools on installation.

f. Department of Defense Dependent Schools (DODDSs).

g. Military Treatment Facilities.

h. Military Police/Security Forces.

3. Reviewed and updated this plan annually through face-to-face meetings with all

Activities involved.

JOHN H. JONES

CPT, VC

Officer in Charge

CF:

COMMANDER, US ARMY GARRISON COMMAND, FORT SAM HOUSTON, TX

COMMANDER, GREAT PLAINS REGIONAL VETERINARY COMMAND

CHIEF, INSTALLATION SUPPORT DIVISION, HQ, VETERINARY COMMAND

MEDCOM Pam 40-13

24

Appendix A – Troop Feeding Support

1. Installation: Fort Sam Houston, TX.

2. Meeting Information

: Meeting conducted between CW2 Ajay, Fort Sam Houston

Branch Veterinary Service; Mr. Smith, Installation Food Advisor (IFA); and MAJ Black,

Chief, Nutritional Support Division, Brooke Army Medical Center, 7 October 2003. This

meeting was conducted immediately after the Installation Menu Board Meeting. The

below schedule of services was agreed upon by all Activities. (List all attendees).

3. Activity Supported

: All dining facilities on post:

bldg # phone # POC

BN DFAC “ “ “

Main DFAC " " "

Warrior DFAC " " "

DFAC 3450 " " "

Hospital DFAC " " "

TISA Cold Storage " " "

(Seasonal support RC/USNG)

4. Support Agreement:

a. Veterinary personnel will support Installation Dining Facilities during the following

time periods:

MON-FRI: 0830-1100

1300-1430

b. Support will be on a rotating basis (area circuit support). Visit each dining hall at

least twice per week.

c. ON-CALL: IAW Posted On-Call Roster (copy given to all parties at meeting;

additional copies given to all dining facility managers, and staff duty officers).

5. Services Provided

:

a. Surveillance product evaluations of items in storage, for condition and obvious

defects, IAW prescribed VETCOM frequencies, directives, and unit SOPs.

b. Complete product evaluations (if directed) for all requirements, IAW prescribed

VETCOM frequencies, directives, and unit SOPs.

MEDCOM Pam 40-13

25

c. Training of receiving personnel on receipt inspection techniques, obvious product

defects, USDA Standards for Grades familiarity, and other public health/food quality

related issues.

(1) Training will be once per month at each dining facility, and will last not longer

than 30-45 minutes.

(2) Vet Service personnel will coordinate best dates/times with each location.

(3) Keep a record of each training session at the Vet Service Branch HQ, and

will also be forwarded to the Installation Food Adviser.

d. Delivery inspections, customer complaints, or other food safety/public health

issues while present.

e. ALFOODACT/local recall and refrigeration breakdown support.

6. Reporting; Points of Contact; Communications:

Upon request, give copies of correspondence and reports to the Authorized Receiving

Individual at the particular site, as well as the Office of the Installation Food Advisor

(Mr. Smith).

MEDCOM Pam 40-13

26

Appendix B – DeCA Support

1. Installation: Fort Sam Houston, TX.

2. Meeting Information: Meeting conducted between CW2 Ajay, Fort Sam Houston

Branch Veterinary Service, and Ms. Sellfood, Commissary Store Director, 1 October

2003. The below schedule of services was agreed upon by both Activities. (List all

attendees).

3. Activity Supported: Main Commissary, Bldg 3.

4. Support Agreement:

Veterinary personnel will support DeCA during the following time periods*:

* (Hours will vary with the agreed upon support and mission requirements, but are not

intended to be 8 continuous hours).

MON-FRI: 0530-0730

1300-1400

1930-2030

SAT: 0600-0730

0930-1030

ON-CALL: IAW Posted On-Call Roster.

5. Services Provided:

a. Approved Sources.

b. Store sanitation walk through inspections (food code, meat market and deli pre-

op and post cleanup, expired items, etc.).

c. Marked down/salvage/survey item inspections.

d. Market Ready Beef / Pork inspections (condition/identity).

e. Fresh dairy & egg inspections.

f. Produce delivery inspections (condition/identity), normally @ 1930.

g. Customer complaint system support (follow up inspections, further requested

assistance, etc.).

MEDCOM Pam 40-13

27

h. Training of store personnel in sanitation, time/temperature concepts, etc.

(production areas).

i. Support during any power outages/refrigeration breakdowns.

j. Any other delivery inspections, or other food safety/public health/wholesomeness

issues while present:

(1) ALFOODACT/local recalls.

(2) In Store Customer Education (through mutual agreement with commissary

management personnel):

(a) Every other month (6 times per year) the commissary will designate a

location within the store for veterinary food inspectors to set up a consumer education

stand (table/booth/etc.).

(b) Inspectors will provide the following, for next CY:

JAN: egg grading demo, w/related egg food safety handout.

MAR: info handouts on Sprouts, and "What's on a label?"

MAY: ground beef fat testing demo, w/related ground beef food safety

handout.

JUL: food safety handouts on oysters; other seafood safety.

SEP: (National Food Safety Month: variety of food safety, foodborne

disease literature distributed).

NOV: Thanksgiving turkey safety; safe holiday food (eggnog, raw cookie

dough, etc.)

6. Reporting; Points of Contact; Communications:

Upon request, give copies of correspondence and reports to the Commissary Director

(Ms. Sellfood) and/or her designated representative.

MEDCOM Pam 40-13

28

Appendix C – AAFES Support

1. Installation: Fort Sam Houston, TX.

2. Meeting Information: Meeting conducted between SFC Wiley, Fort Sam Houston

Branch Veterinary Service, and Mr. Dogood, Main AAFES Procurement Office, 9

October 2003. The below schedule of services was agreed upon by both Activities.

(List all attendees).

3. Activity Supported: All Shoppettes, retail food outlets, and other AAFES managed

facilities selling food on the Installation.

a. Main PX and Food Courts (Robin Hood, Steak' M, etc).

b. Main Shoppette.

c. Montgomery Shoppette.

d. Gas Station #1.

e. Gas Station #2.

f. BN Retail Shop.

g. NCO Academy Bookstore.

h. Bowling Alley.

i. Beverage Store.

4. Support Agreement

:

a. Veterinary personnel will support Installation AAFES Facilities during the

following time periods:

MON-FRI

: 0830-0930

1430-1530

b. Support will be on a rotating basis (area circuit support). Visit each location at

least twice per week.

ON-CALL: IAW Posted On-Call Roster (copy given to all parties at meeting;

additional copies given to all dining facility managers, and staff duty officers)

MEDCOM Pam 40-13

29

5. Services Provided:

a. Formal and informal sanitation inspections. This will include visual inspections of

ice producing machines if present, and may include periodic swabbing of ice producing

equipment. End-item lab sampling may be performed on finished bagged ice and any

other food items sold.

b. Delivery inspections, customer complaints, potentially hazardous foods (PHFs),

product cursory checks, or other food safety/public health/wholesomeness issues while

present, or when notified.

c. Training.

(1) Fresh Dairy inspections via commissary stop point inspection.

(2) Product evaluations IAW Exchange Services policies.

(3) ALFOODACT/local recalls and refrigeration breakdown support.

(4) Education of receiving personnel through pamphlets, literature, training, etc.

6. Reporting; Points of Contact; Communications:

Upon request, give copies of correspondence and reports to the appropriate activity

manager, as well as the Installation Exchange Procurement Office (Mr. Dogood).

MEDCOM Pam 40-13

30

Appendix D – MWR Support: FOOD

1. Installation: Fort Sam Houston, TX.

2. Meeting Information: Meeting conducted between CW2 Ajay, Fort Sam Houston

Branch Veterinary Service, and Mr. Reynolds, MWR Procurement Office, 9 October

2003. The below schedule of services was agreed upon by both Activities. (List all

attendees).

3. Activity Supported: All retail food outlets, and other MWR managed facilities selling

or providing food on the Installation.

a. Officers Club.

b. NCO Club.

c. Rod & Gun Club.

d. Child Care Center.

e. Golf Course Club.

f. ACS Food Locker.

g. Recreation Center.

h. Main Gymnasium.

i. Youth Activity Center.

4. Support Agreement

:

a. Veterinary personnel will support Installation MWR Facilities during the following

time periods:

MON-FRI

: 0830-0930

1430-1530

b. Support will be on a rotating basis (area circuit support). Visit each location at

least twice per week.

ON-CALL: IAW Posted On-Call Roster (copy given to all parties at meeting;

additional copies given to all facility managers, and staff duty officers).

MEDCOM Pam 40-13

31

5. Services Provided:

a. Informal sanitation inspections.

b. Delivery inspections, customer complaints, product cursory checks, or other food

safety/public health/wholesomeness issues while present, or when notified.

c. Milk inspections via commissary stop point inspection.

d. ALFOODACT/local recalls and refrigeration breakdown support.

e. Education of receiving personnel through pamphlets, literature, training, etc.

6. Reporting; Points of Contact; Communications:

Upon request, give copies of correspondence and reports to the appropriate activity

manager, as well as the Installation MWR Procurement Office (Mr. Reynolds).

MEDCOM Pam 40-13

32

Appendix D – MWR Support: ANIMAL

1. Installation: Fort Sam Houston, TX.

2. Meeting Information: Meeting conducted between CPT Able, Fort Sam Houston

Branch Veterinary Service; Mr. Park, MWR Chief; and Mrs. Blue, MWR Finance Officer,

1 October 2003. The below schedule of services was agreed upon by both Activities.

(List all attendees.)

3. Activity Supported:

a. Veterinary Treatment Facility.

b. Child Development Centers (that maintain live animals as room pets or projects).

c. NAF owned animals.

4. Support Agreement:

a. Veterinary personnel will operate the Veterinary Treatment Facility during the

following time periods:

MON-FRI: 0800-1600

b. Veterinary personnel will support the Child Development Center during the

following time periods:

MON-FRI: During on-duty hours, 0730-1630, as needed and upon request.

5. Services Provided

:

a. Operate the VTF for animals owned by personnel authorized DOD medical care.

b. Perform not less than monthly inspections of all classrooms that keep live

animals as class pets or projects. Health and care of the animals will be evaluated as

well as the sanitary and safety aspects of cages or other enclosures.

c. NAF owned animals will be provided preventive veterinary medical care as

resources allow, on a reimbursable basis. Complete veterinary medical and surgical

care may be provided on a reimbursable basis, as time, expertise, and resources allow.

MEDCOM Pam 40-13

33

6. Reporting; Points of Contact; Communications:

a. Upon request, give copies of CDC correspondence and reports to the CDC

Director or other designated individual.

b. Provide financial documents and reports as required by the NAF financial office.

MEDCOM Pam 40-13

34

Appendix E – General Installation/Area Support

ABC Reserve Center

1. Installation/Area

: Fort Sam Houston, TX.

2. Meeting Information

: Meeting conducted between CW2 Ajay, Fort Sam Houston

Branch Veterinary Service, and MSG Kline, ABC Reserve Center, 10 October 2003.

The below schedule of services was agreed upon by both Activities. (List all attendees).

3. Activity Supported: General Installation/Area support covers those activities that do

not fall under previously identified appropriated or non-appropriated fund activities. This

support agreement covers the following:

ABC Reserve Center.

4. Support Agreement:

Veterinary personnel will support the ABC Reserve Center during the following time

periods:

MON-FRI: During on-duty hours, 0600-1700, and upon request.

ON-CALL: IAW Posted On-Call Roster (copy given to all parties at meeting, and

staff duty officers).

5. Services Provided:

a. The ABC Reserve Center ration storage site will have ration surveillance

inspections provided IAW prescribed VETCOM frequencies, directives, and unit SOPs.

b. Provide on-site sanitation assessment of ration storage conditions.

c. ALFOODACT/local recalls and refrigeration breakdown support as applicable.

d. Food safety as well as Operational Ration quality education of personnel through

appropriate literature.

6. Reporting; Points of Contact; Communications:

Upon request, give copies of correspondence and reports to the appropriate activity

manager (MSG Kline).

MEDCOM Pam 40-13

35

Coast Guard Supply Center

1. Installation/Area: Fort Sam Houston, TX.

2. Meeting Information

: Meeting conducted between CW2 Ajay, Fort Sam Houston

Branch Veterinary Service, and Mr. Carter, Coast Guard Support Center, 10 October

2003. The below schedule of services was agreed upon by both Activities. (List all

attendees).

3. Activity Supported

: General Installation/Area support covers those activities that do

not fall under previously identified appropriated or non-appropriated fund activities. This

support agreement covers the following:

Coast Guard Supply Center.

4. Support Agreement:

Veterinary personnel will support the Coast Guard Supply Center during the following

time periods:

MON-FRI: During on-duty hours, 0600-1700, and upon request.

ON-CALL: IAW Posted On-Call Roster (copy given to all parties at meeting, and

staff duty officers).

5. Services Provided:

a. The Coast Guard Supply Center ration storage site will have ration surveillance

inspections provided IAW prescribed VETCOM frequencies, directives, and unit SOPs.

b. Provide on-site sanitation assessment of ration storage conditions.

c. ALFOODACT/local recalls and refrigeration breakdown support as applicable.

d. Food safety as well as Operational Ration quality education of personnel through

appropriate literature.

6. Reporting; Points of Contact; Communications:

Upon request, give copies of correspondence and reports to the appropriate activity

manager (Mr. Carter).

MEDCOM Pam 40-13

36

Food Security and Vulnerability Assessments

1. Installation/Area: Fort Sam Houston, TX.

2. Meeting Information

: Meeting conducted between CPT Jones, Fort Sam Houston

Branch Veterinary Service, and COL Rogers, Garrison Commander, Fort Sam Houston,

10 October 2003. The below support was agreed upon by both parties. (List all

attendees).

3. Activity Supported

: General Installation/Area support covers those activities that do

not fall under previously identified appropriated or non-appropriated fund activities. This

support agreement covers the following:

Food Security and Vulnerability Assessments.

4. Support Agreement:

Veterinary personnel will fully support the Food Safety Assessment Team (FSAT)

assembled at the Installation level. Veterinary personnel are available during normal

duty hours as well as off duty hours, 7 days a week.

MON-FRI: 0600 – 1700 or as needed

ON-CALL: IAW Posted On-Call Roster (copy given to all parties at meeting, and

staff duty officers).

5. Services Provided:

a. Assessment support as determined by the FSAT leader.

b. Semi-annually, as part of the applicable sanitary inspections, review and provide

an assessment of food security practices.

(1) Assessment is for obvious food security concerns noted.

(2) Conducted only on those facilities the veterinary service has the authority to

inspect.

(3) Intended to supplement (not replace) the Installation level assessments.

(4) Supported as a team member vs. team leader.

6. Reporting; Points of Contact; Communications:

MEDCOM Pam 40-13

37

Give copies of the semi-annual report, which includes food security to the Office of the

Garrison Commander, and each applicable Installation procurement office.

Support of Installation Special Events

1. Installation/Area: Fort Sam Houston, TX.

2. Meeting Information: Meeting conducted between CPT Jones, Fort Sam Houston

Branch Veterinary Service, and COL Rogers, Garrison Commander, Fort Sam Houston,

10 October 2003. The below support was agreed upon by both parties. (List all

attendees).

3. Activity Supported: General Installation/Area support covers those activities that do

not fall under previously identified appropriated or non-appropriated fund activities. This

support agreement covers the following:

Support of Installation Special Events.

4. Support Agreement:

The mission of food service sanitation on the Installation belongs to the local preventive

medicine activity. However, Veterinary personnel will be on-call to support any food

safety, wholesomeness, or security problems encountered during these special events.

ON-CALL: IAW Posted On-Call Roster (copy given to all parties at meeting, and

staff duty officers).

5. Reporting; Points of Contact; Communications:

Give copies of all correspondence and reports that result from veterinary support to the

Office of the Garrison Commander, and the Hospital Commander.

Support of Installation and Area Exercises/Survival training field activities

1. Installation/Area

: Fort Sam Houston, TX.

2. Meeting Information

: Meeting conducted between CPT Jones, Fort Sam Houston

Branch Veterinary Service; COL Rogers, Garrison Commander, Fort Sam Houston; and

COL Kilroy, Commandant, Special Forces Training Center, 10 October 2003. The

below support was agreed upon by both parties. (List all attendees).

3. Activity Supported: General Installation/Area support covers those activities that do

not fall under previously identified appropriated or non-appropriated fund activities. This

support agreement covers the following:

MEDCOM Pam 40-13

38

Support of Installation and Area Exercises/Survival training field activities.

4. Support Agreement:

Veterinary personnel will fully support any Installation or area Exercise requiring our

food safety/security and quality assurance support. Veterinary personnel are available

during normal duty hours as well as off duty hours, 7 days a week.

MON-FRI: 0600 – 1700 or as needed.

ON-CALL: IAW Posted On-Call Roster (copy given to all parties at meeting, and

staff duty officers).

5. Services Provided:

a. Services provide will include food safety, security, approved sources, quality

assurance, and wholesomeness, as required and determined by the particular exercise.

b. The same service will be provided for the Special Forces School here, which

conducts emergency field slaughters 3 times a year.

c. The Special Forces School will contact the veterinary service office 2 weeks prior

to the start of their training exercise, to receive training in foodborne disease, safe

cooking and handling procedures, and sanitation.

6. Reporting; Points of Contact; Communications:

a. Give reports of veterinary support, issues, and lessons learned to the Installation

Commander/appropriate exercise POC.

b. Provide a record of training to the Special Forces Training Center Commandant.

Housing Office and animal welfare/pets

1. Installation

: Fort Sam Houston, TX.

2. Meeting Information

: Meeting conducted between CPT Able, Fort. Sam Houston

Branch Veterinary Service, and Mrs. Green, Housing Officer, 1 October 2003. The

below schedule of services was agreed upon by both Activities. (List all attendees.)

3. Activity Supported

: Issues concerning the Housing Office and animal welfare/pets.

4. Support Agreement

:

Veterinary personnel will support the Housing Office during the following time periods:

MEDCOM Pam 40-13

39

MON-FRI: During on-duty hours, 0730-1630, as needed and upon request.

5. Services Provided:

a. Advise the Housing Office regarding pets in housing. Note: The installation

commander has given responsibility for animal control (capture of strays) to the MPs.

b. Assist with any investigations of animal welfare in housing units. Housing must

supply personnel to accompany any veterinary personnel into the housing unit; typically

the MPs are involved in the investigation.

c. Any impoundment of pets must be coordinated between housing and the MPs;

veterinary services personnel do not have authority to remove pets from housing areas

without owner permission.

6. Reporting; Points of Contact; Communications:

Give copies of all correspondence and reports to the Housing Officer or other

designated individual.

Public Works/Wildlife Management/Pest Management/Post Engineers

1. Installation: Fort Sam Houston, TX.

2. Meeting Information: Meeting conducted between CPT Able, Fort. Sam Houston

Branch Veterinary Service, and Mr. Purple, Public Works Officer, 1 October 2003. The

below schedule of services was agreed upon by both Activities. (List all attendees.)

3. Activity Supported: Public Works/Wildlife Management/Pest Management/Post

Engineers.

4. Support Agreement

:

Veterinary personnel will support the Public Works Office during the following time

periods:

MON-FRI

: During on-duty hours, 0730-1630, as needed and upon request.

5. Services Provided:

a. Advise/assist on issues of animal control, particularly if considering euthanasia or

controlled drugs.

b. Provide veterinary support for stray animal impoundment facilities.

MEDCOM Pam 40-13

40

c. Perform not less than quarterly inspections of all stray animal impoundment

facilities. Health and care of the animals will be evaluated as well as the sanitary and

safety aspects of cages or other enclosures.

6. Reporting; Points of Contact; Communications

:

Give copies of all correspondence and reports to the Public Works Officer or other

designated individual.

G3 Operations

1. Installation

: Fort Sam Houston, TX.

2. Meeting Information: Meeting conducted between CPT Able, Fort Sam Houston

Branch Veterinary Service, and COL Delta, G3, 1 October 2003. The below schedule of

services was agreed upon by both Activities. (List all attendees.)

3. Activity Supported: G3 Operations.

4. Support Agreement:

Veterinary personnel will support the G3 during the following time periods:

MON-FRI: During on-duty hours, 0730-1630, as needed and upon request.

5. Services Provided:

a. The veterinary officer is the commander’s consultant on the humane use and

care of animals.

b. Assist with use of animals in field survival training, and other uses of animals.

6. Reporting; Points of Contact; Communications:

Give copies of all correspondence and reports to the G3 or other designated individual.

MEDCOM Pam 40-13

41

Appendix F – Department of Defense Dependent Schools

1. Installation: Fort Sam Houston, TX.

2. Meeting Information: Meeting conducted between CPT Able, Fort Sam Houston

Branch Veterinary Service; Mrs. Smith, School Principal; and Mrs. Jones, School Nurse,

1 October 2003. The below schedule of services was agreed upon by both Activities.

(List all attendees.)

3. Activity Supported: Any schools on the installation that keep live animals as class

pets or projects.

4. Support Agreement:

Veterinary personnel will support the DODDS during the following time periods:

MON-FRI: During on-duty hours, 0730-1630, as needed and by appointment

5. Services Provided:

Perform not less than quarterly inspections of all classrooms that keep live animals as

class pets or projects. Health and wellbeing of the animals will be evaluated as well as

the sanitary and safety aspects of cages or other enclosures.

6. Reporting; Points of Contact; Communications:

Give copies of all correspondence and reports to the School Principal, School Nurse, or

other designated individual.

MEDCOM Pam 40-13

42

Appendix G– Military Treatment Facility

1. Installation: Fort Sam Houston, TX.

2. Meeting Information

: Meeting conducted between CPT Able, Fort Sam Houston

Branch Veterinary Service; COL Cough, Hospital Director; CPT Stat, Chief of ER; and

MAJ Pills, Chief of Pharmacy, 1 October 2003. The below schedule of services was

agreed upon by both Activities. (List all attendees.)

3. Activity Supported

:

a. MTF wards.

b. Emergency Room.

c. Pharmacy.

4. Support Agreement:

Veterinary personnel will support the Military Treatment Facility during the following time

periods:

MON-FRI: During on-duty hours, 0730-1630, as needed upon request.

ON-CALL: As needed IAW Posted On-Call Roster (copy given to all parties at

meeting, and staff duty officers).

5. Services Provided:

a. Support to the Emergency Room in management of animal bite cases and

reports.

b. Training of Emergency Room personnel in management of animal bite cases and

reports, as needed.

c. Support to human animal bond programs, as needed.

d. Coordinate with Pharmacy for monthly controlled substances inventories and

disposal issues.

6. Reporting; Points of Contact; Communications

:

a. Identify POCs in the ER for issues that arise with bite reports.

b. Respond to controlled substances inventory discrepancies as needed.

MEDCOM Pam 40-13

43

Appendix H – Military Police/Security Forces

1. Installation: Fort Sam Houston, TX.

2. Meeting Information: Meeting conducted between CPT Able, Fort Sam Houston

Branch Veterinary Service, and LTC Handsup, MP Commander, 1 October 2003. The

below schedule of services was agreed upon by both Activities. (List all attendees.)

3. Activity Supported: Fort Sam Houston Military Police.

4. Support Agreement:

Veterinary personnel will support the Military Police during the following time periods:

MON-FRI: During on-duty hours, 0730-1630, as needed upon request.

ON-CALL: As needed IAW Posted On-Call Roster (copy given to all parties at

meeting, and staff duty officers).

5. Services Provided:

a. Random cursory inspections of vehicles carrying food or water at the vehicle

entry control point. This will be performed at a minimum of once/week.

b. Complete veterinary medical and surgical care for Military Working Dogs

(MWDs), including a veterinary preventive medicine program.

c. Provide a plan for veterinary care of MWDs when military veterinary personnel

are not available.

d. Sanitary inspections of MWD kennels on at least a quarterly basis. More

frequent courtesy visits are encouraged.

e. Training of handlers and supervisors on the health, care, and management of

MWDs upon initial assignment of the handlers and at least annually thereafter. More

frequent training is recommended but not required.

f. Advise the installation Military Police Commander on all matters pertaining to the

health and wellbeing of MWDs.

g. Review and approve any plans for new construction or modification of existing

kennels.

h. Assist with animal welfare investigations of alleged abuse or neglect.

MEDCOM Pam 40-13

44

i. Assist with animal control issues.

j. Request physical security surveys and inspections of locations where narcotics,

dangerous drugs, and controlled substances are stored.

6. Reporting; Points of Contact; Communications:

a. Provide the MP Commander and kennel master a copy of the MWD Deployability

Status Report on a monthly basis.

b. Provide the MP Commander and kennel master copies of all kennel inspections

and other correspondence regarding MWDs, to include disposition letters and death

certificates.

MEDCOM Pam 40-13

45

Figure 3.2 – Installation Support Plan Database Review

Branch Level Monthly Review:

Week Of: Activities/

Reports Being

Reviewed

CVRs:

Correct

Number

IAW Risk,

agreements

; Accurate

SIRs:

Accurate;

Appropriate

Contact

Reports

Freq. &

risk

levels

vs. ISP

Risk

levels:

How

many

high

risk;

Appropr

iate

severity

Actions

Taken

Oct 3-7 DeCA 1 visit not

made due to

training; 1

incorrect

CVR

4 SIRs were

incorrect; 2

should have

been

completed

but were not

GO Low risk

Further training on

reports

Oct 10-14 Troop Feeding 2 Inaccurate

CVRs

1 incorrect

SIR

GO 2 High

Risk

DFACs;

All

others

Moderate

Further training on

reports

Oct 17-21 AAFES/MWR 2 additional

visits

required

GO NO-GO 2 High

Risks

wrongly

listed as

Moderate

Further training on

Risk assessments

Oct 24-28 All Other GO 1 SIR

incorrect, at

Warfare

Training

School

GO GO Further training on

reports

District Level Monthly Review:

Week Of: Branch Bein

g

Reviewed

Activities/Reports

Being Reviewed

Actions Taken

Oct 3-7 Carlisle All CVRs