1

Pollution Incident Response Management Plan_Rev4_31/03/2019

Testing of the plan

Document Tested/test report

Test Date

Manner of Testing

Tested by

PIRMP_ Rev_ 3

\\192.168.1.10\Public\08.

Engineering &

Administration\Environmental

Management\EMP

25 March 2019

Desktop review

Rob Young and Ben

Warner

Document uncontrolled when printed

2

Pollution Incident Response Management Plan_Rev4_31/03/2019

Appendix G

Pollution Incident Response Management Plan

1. Background

The Kurnell Land Fill is operated by Breen Resources Pty Ltd under licence 4608. The purpose of this Pollution

Incident Response Management Plan (PIRMP) is to define the way pollution incidents are reported, managed and

communicated to the general community, and to the relevant NSW Government Authorities and Services.

As defined by the EPA guidelines, the purpose of this plan is to:

• Ensure comprehensive and timely communication about a pollution incident to staff at the premises, the

Environment Protection Authority (EPA), other relevant authorities specified in the Act (such as local

councils, NSW Ministry of Health, WorkCover NSW, and Fire and Rescue NSW) and people outside the

facility who may be affected by the impacts of the pollution incident

• Minimise and control the risk of a pollution incident at the facility by requiring identification of risks and the

development of planned actions to minimise and manage those risks

• Ensure that the plan is properly implemented by trained staff, identifying persons responsible for

implementing it, and ensuring that the plan is regularly tested for accuracy, currency and suitability.

2. Description of likely Hazards

Breen Resources Pty Ltd accepts waste for disposal at its landfill and for recycling. It also accepts VENM material for

landfill closure and adjacent Parklands Construction.

Likely hazards have been assessed and include the following:

Potential Hazard

Likelihood of occurrence

Events that could increase likelihood

Dust

High

Dry, windy conditions

Odour

Low

Low wind, high temp

Noise

Low

Specific activities outside normal operations

Fuel Spill

Low

Bund failure

Oil/Lube spill

Low

Bund failure

Chemical spill

Low

Increase currently low volumes of chemical

use (cleaning products etc)

Fire

Med

Prolonged dry weather, incompatible waste

types being mixed together, smoking on site

Leachate spill

Low

Prolonged wet weather

Contaminated Fill

(VENM)

Low

Lack of governance relating to verification of

source material.

3

Pollution Incident Response Management Plan_Rev4_31/03/2019

Discovery of

Radioactive

Material

Low

Lack of governance relating to verification of

source material.

Stormwater

contamination

Low

A leachate spill resulting from prolonged wet

weather.

Discovery of

hazardous waste

Low

Increasing gate fees and NSW waste levy on

special and restricted wastes may lead to

customers attempting to dispose of more

hazardous materials (asbestos etc) at Breen

Resources Pty Ltd

Breen Resources Pty Ltd (Breen) is located in a relatively unpopulated area of the Kurnell Peninsula. It is recognised

however that due to recent re-zoning activities at Greenhills Beach, there may be increased impacts due to a dust or

stormwater pollution incident. It is also recognised that Breen is located near Quibray Bay and its sensitive

ecosystem that also may result in increased impacts from a leachate spill.

3. Pre-Emptive Actions

Control measures to minimise or prevent the risk of harm to the environment or human health arising from landfilling

and recycling activities are described below:

Potential Hazard

Pre-emptive Actions

Dust

• Use of two water trucks (approx. 15,000L) used on the site to supress dust on

haul roads during summer months and one water truck during winter months (or

as conditions require), additional portable water tanks and water storage is also

available on site. Sprinklers used to supress dust on gypsum and recycled

aggregate stockpiles and screening/crushing plant.

• Crushing and gypsum processing operations cease in windy conditions that

exceed 30km/hr.

Odour

• Use of appropriate daily and intermediate cover.

• Putrescible wastes not accepted.

• There is a low risk of odour causing an impact on neighbours.

Noise

• Use of noisy equipment in isolated and low lying areas of the site.

• All machinery is regularly maintained and serviced to ensure compliance with

manufacturers standards.

• There is a low risk of noise causing an impact on neighbours.

Fuel Spill

• Use of hydrocarbon spill response kits,

• appropriately sized bunding of above ground storage tanks,

• staff training - tool box talks and safety meetings

• regular inspections of tanks

• groundwater monitoring per EPL

Oil/Lub spill

• Use of hydrocarbon spill response kits,

• appropriately sized bunding of above ground oil storage tanks,

4

Pollution Incident Response Management Plan_Rev4_31/03/2019

• staff training - tool box talks and safety meetings

• regular inspections of tanks

• groundwater monitoring per EPL

Chemical spill

• Storage of limited volumes of chemicals in a dry locked store

• Use of chemical spill kits

• staff training - tool box talks and safety meetings

• use of appropriate PPE (gloves, mask )

Fire

• Use of water carts with water cannons, readily available water from dams on site,

Additional portable water is available in water tanks

• Inspection by NSWFB of premises to familiarise site layout and hazards

• Smoking being restricted to designated areas away from any waste

• Segregation of waste types to ensure like materials are grouped together

• Fire extinguishers on most plant and regularly serviced

• Cover material readily available on site

Leachate spill

• Leachate management plan

• Appropriately sized and maintained leachate bund

• Use of two pumps to manage the evaporation of leachate on site

• Regular monitoring and inspection to ensure properly maintained.

Contaminated Fill

(VENM)

• Site inspection and validation records by Breen staff

• Inspection of all material at the weighbridge

• Inspection of material when being tipped in its final location.

• Scientific analysis of material as required

Discovery of

Radioactive

Material

• Environmental reporting on General Solid Waste prior to acceptance

• Confirmation that retrieved metal is free from Radioactive material by Metal

Recyclers

Stormwater

contamination

• Appropriately sized stormwater detention pond

• Stormwater flows directed to the appropriate collection systems

• Regular monitoring and inspection to ensure system is maintained.

Discovery of

hazardous waste

• staff training - tool box talks and safety meetings

• notification of appropriate authorities

• Involvement of senior management

Breen Resources Pty Ltd has an inventory of hazardous substances and their MSDS details available at the site

office. This inventory is updated on a regular basis.

Inventory of pollutants stored on site include:

Name

Hazardous?

Amount

Stored (L)

Location & method of storage

Fuel (diesel)

Yes

20,000

Self Bunded Above ground storage tank – refer map.

Oil

Yes

2500

Workshop (bunded) – refer map

Coolant

Yes

100

Workshop (bunded) – refer map

5

Pollution Incident Response Management Plan_Rev4_31/03/2019

Regenesis

(Oxidizer)

Yes

3,500 KG

Brown container opposite workshop (locked)

Misc

workshop

Chemicals

Yes

60

Workshop (bunded in chemical container) – refer map

Compressed

Gasses

Yes

60

Workshop – refer map

Cleaning

Chemicals

Yes

20

Lab Store – refer map

4. Safety Equipment

Breen Resources Pty Ltd have the following safety equipment readily available to staff, used to minimise the risk to

human health and the environment:

• Hard Hats,

• Safety glasses (tinted and non-tinted)

• Hats

• Sun cream

• Clothing (long sleeve, robust clothes)

• Safety boots

• Masks (P2)

• Overalls (disposable)

• Gloves (leather and synthetic)

• First aid kits.

• Spill kits

• Fire extinguishers

All safety equipment is stored in the site office and available during working hours. As noted above, the Breen

Resources Pty Ltd has an inventory of hazardous substances and their MSDS details available at the site office. Spill

kits are located in the workshop. Fire extinguishers are in all areas and mobile plant.

Each item of equipment operated on the site has a safe work method statement (SWMS) that contains specific risks

and management methods to minimise risks to human health and the environment. These SWMS are routinely

reviewed, discussed at the monthly safety meeting and training on the SWMS is provided to all staff. These SWMS

are available at the site office.

6

Pollution Incident Response Management Plan_Rev4_31/03/2019

5. Contact Details and notification procedure

• Insure safety first on site

If an injury occurs Dial 000

Breen Resources Pty Ltd

Site Address: 330 Captain Cook Drive, Kurnell

Nearest Cross Street: Bate Bay Road

• Decide if a pollution incident has occurred

‘Material harm to the environment’, is defined in section 147 of the POEO Act as:

An environmental incident has occurred when:

o It involves actual or potential harm to the health or safety of human beings or to

ecosystems which are not trivial, or

(ii) It results in actual or potential loss or property damage of an amount, or

amounts in aggregate, exceeding $10,000 (or such other amount as is prescribed

by the regulations), and

o Loss includes the reasonable costs and expenses that would be incurred in taking

all reasonable and practicable measures to prevent, mitigate or make good harm to

the environment.”

• Information to be provided to authorities

o The time, date, nature, duration and location of the incident

o The location of the place where pollution is occurring or is likely to occur

o The nature, the estimated quantity or volume and the concentration of any pollutants involved, if

known

o The circumstances in which the incident occurred, including the cause of the incident, if known

o The action taken or proposed to be taken to deal with the incident and any resulting pollution or

threatened pollution, if known

o Other information prescribed by the regulations

• 24 Hour Site Contact authorised to contact the authorities:

i. Damien Vella 0420 890 065 CEO

ii. Michael Glass 0429 956 194 Operations Manager

iii. Ian Spencer 0418 274 468 Site Manager

iv. Rob Young 0412 058 244 Safety Officer

v. Jonathan Mosley 0421 840 486 Superintendent

vi. Terry May 0424 296 576 Site Foreman

vii. Ben Warner 0402 232 619 Project Engineer

• If incident meets definition then IMMEDIATELY notify:

o EPA – Hot Line 131 555

Kurnell Land Fill Company EPA Licence 4608

o The Sutherland Shire Council

General Line (02) 9710 0333

o The Ministry of Health (via Public Health Units)

7

Pollution Incident Response Management Plan_Rev4_31/03/2019

South Eastern Area Health Service (02) 9382 2222

Sutherland Hospital (02) 9540 7111

o WorkCover NSW

Hot Line 13 10 50

o Fire and Rescue NSW

Cronulla Brigade (02) 9527 2223

o Police

Cronulla Police (02) 95278199

• If Directed to notify Neighbours

Cronulla Treatment Works

Contact line 24 hour: (02) 9527 8310

Stand by: 0417 468 239

Holt Land Rehabilitation Centre (Quarry): (02) 9923 1944

Frasers Property Group

Greenhills Estate (Edward Murray-Development Manager): (02) 9767 2152

0407 744 153

6. Communicating with Neighbours and the local community

In section 2 of this plan, an assessment of typical pollution incidents have been assessed. This has resulted in

the schedule that outlines the potential pollutants, impacts and early warning mechanisms:

Potential Hazard

Potential Risk

Early Warning Action

Dust

Loss of amenity.

Complaints.

In extreme cases, contact neighbours via

doorknock, phone calls or email. Ask

residential neighbours to close windows and

doors.

Odour

Loss of amenity.

Complaints.

In extreme cases, contact neighbours via

doorknock, phone calls or email. Ask

residential neighbours to close windows and

doors.

Noise

Loss of amenity.

Complaints.

Is not anticipated to be required.

Fuel Spill

Damage to the

environment.

Complaints.

For larger spills, contact agencies per section

6 of this plan.

Oil/Lub spill

Damage to the

environment.

Complaints.

For larger spills, contact agencies per section

6 of this plan.

Chemical spill

Damage to the

environment.

Complaints.

For larger spills, contact agencies per section

6 of this plan.

8

Pollution Incident Response Management Plan_Rev4_31/03/2019

Leachate spill

Damage to the

environment.

Complaints.

For larger spills, contact agencies per section

6 of this plan.

Contaminated Fill

(VENM)

Damage to the

Environment

For larger contamination events, contact

agencies per section 6 of this plan.

Discovery of

Radioactive

Material

Damage to the

Environment

For all discoveries, contact ANSTO (02

9717 3111) and the agencies per section

6 of this plan.

Stormwater

contamination

Damage to the

environment.

Complaints.

For larger contamination events, contact

agencies per section 6 of this plan.

Discovery of

hazardous waste

Damage to the

environment.

Complaints.

Contact agencies per section 6 of this plan.

7. Minimising harm to persons on the premises

Breen Holdings have a central evacuation meeting place that is located adjacent to the site office. All staff are

contactable on mobile and 2-way in the event that an evacuation is required. An evacuation procedure is

documented and on display in the site office.

The premises is secure and the site compound (where hazardous material is stored) is fenced and alarmed to

ensure hazardous materials are secure and cannot be tampered with.

During any incident response, the progress and proposed next steps are to be communicated to relevant

stakeholders, agencies and senior management.

Once the incident is finalised, notification is to be issued to the relevant authorities indicating same.

8. Availability of this Plan

Printed copies of this plan are available to those responsible for implementing the plan, at the site office.

9. Staff Training

This Plan is to be implemented through staff training. Staff training takes the form of ensuring staff are aware of

the location of the plan and its contents. It also ensures that the relevant contact personnel are known by staff

in the case an incident occurs. During Breen Resources Pty Ltd regular site safety meetings, hazards and

Breen’s responses to these hazards are discussed. Preventative measures, e.g the clean out of leachate

management ponds are raised in this forum.

9

Pollution Incident Response Management Plan_Rev4_31/03/2019

10. Updating of this Plan

This plan is due to be updated on 31 March 2024.

This update is to ensure that all information within this plan is accurate and up to date, and is capable of being

implemented in a workable and effective manner.

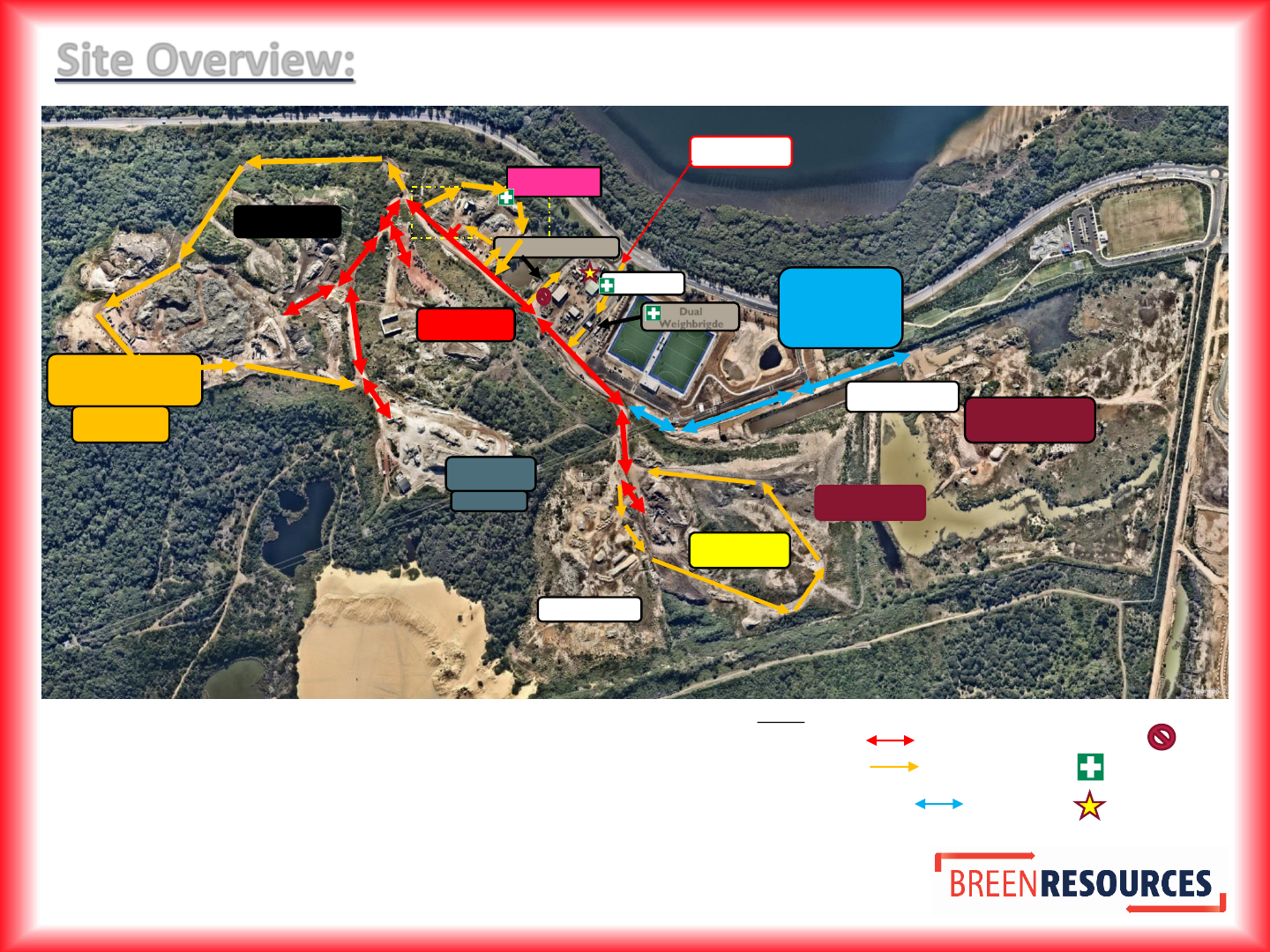

11. Maps

Appendix 1 contains the following maps

• Map 1: Overall site context

• Map 2: Location of hazardous materials on the Breen Resources Pty Ltd site.

It is noted that all stormwater is managed on site, through the use of onsite detention systems.

➢ Speed Limit is 25 Kph on haul roads (main site roads) & 10 Kph in

work site zones (where people & machines are operating)

➢ Radio Channels;

❖ GSW & Soil Recycling: UHF 11

❖ Landfill: UHF 11

❖ Recycling Plant: UHF 36

❖ Soil Pick Up: UHF 11

❖ Bin Storage: UHF 11

❖ Regyp / Plaster: UHF 10

❖ Concrete Recyclers: UHF 34

❖ Construction area UHF 15

Site Overview:

Empty Bin

Storage

Current

Landfill Cell

Landfill cell under

construction

Pond Zero

Recycling, Concrete,

Brick and Sandstone

GSW & Soil

Recycling

Wheel wash

Site Entry/Exit

Recycle Soil

Storage

Leachate pond

Emergency

Evac. Point

Concrete

Recyclers

Gypsum

recycling

Regyp

Heavy Machinery Entry

Dual

Weighbrigde

Office

1st Aid Kits

Recycle

Plant

To

Construction

Authorised

personnel only

Legend

Two way roads

One way Roads

To Construction

Authorised Personnel

Only

➢ Site Amenities:

❖ Carpark

❖ Lunch Room

❖ Site Office

❖ Male Toilets

❖ Female Toilets

❖ Showers

❖ Weighbridge

❖ Workshops – Oils, Coolant,

Gas, misc workshop chemicals

❖ Fuel tank

❖ Oxidizer in container

❖ Wheelwash

❖ First Aid Kits

(Weighbridge & Site Office)

❖ Safety Data Sheets (SDS)

(Online in Skytrust)

❖ General Rubbish Bin

❖ Emergency Evacuation

Point

❖ Spit Kit

Site Orientation:

❖ In & Out via Captain Cook Drive Gate Only

❖ All visiting Personnel must first report to the Site Office

❖ All visiting Personnel must Sign In & Out of the visitor book

❖ All vehicles must leave via the wheel wash