1

Allergen Immunotherapy

Extract Preparation

Instructional Guide

Revised October 2019

AUTHORS

Peter Mustillo, MD

Bryan L. Martin, DO, FACAAI

John Oppenheimer, MD, FACAAI

Michael R. Nelson, MD, PhD, FACAAI

2

Table of Contents

I. Introduction .......................................................................................3

II. Allergen Extracts.................................................................................... 4

III. Allergen Extract Mixing Standards Qualifications, and Competencies ......................................5

IV. Allergy Immunotherapy Prescriptions..................................................................7

V. Color Coding, Labels and Beyond Use Dates (BUD) ..................................................... 9

VI. Mixing Individual Patient Allergen Extract Treatment Sets................................................10

VII. Stinging Insect Allergen Extract Preparation ...........................................................15

VIII. Allergen Extract Stability and Storage.................................................................16

IX. Summary .........................................................................................17

X. Acknowledgments .................................................................................18

XI. References ........................................................................................18

XII. Appendices

Appendix 1. Effective Dose Range for Allergen Extracts, US Standardized Units ............................20

Appendix 2. Initial and Ongoing Competency Assessment: Allergen Extract Mixing ........................21

Appendix 3. Extract Volumes Needed for 5.0 ml Maintenance Vials.......................................22

Appendix 4. Recommended Documentation for Allergen Immunotherapy Extract Prescription Forms

and Allergen Immunology Extract Prescription Form ........................................23

Appendix 5. USP Section 21 — Compounding Allergenic Extracts ........................................25

Appendix 6. Forms

Competency Assessment — Initial Personnel Training: Allergen Extract Mixing............................30

Competency Assessment — Annual Personnel Training: Allergen Extract Mixing ..........................32

Competency Assessment — Aseptic Technique and Related Practices of Mixing Personnel .................34

Competency Assessment — Hand Hygiene and Garbing Procedures ....................................36

Competency Assessment — Cleaning and Disinfecting Procedures......................................38

Complaints/Adverse Effects .......................................................................40

Gloved Fingertip and Thumb Sampling .............................................................41

Media-fill Testing Checklist ........................................................................42

Primary Engineering Control (PEC) Hood............................................................43

Refrigerator Temperature Log......................................................................44

©2019 ACAAI

3

I. INTRODUCTION

Origins of Allergy Immunotherapy

Allergen immunotherapy was first introduced

by Leonard Noon in 1911.

1

Dr. Noon originally

hypothesized that patients suffering from “hay fever”

were sensitive to a “toxin” contained in grass pollen. He

proposed that patients would benefit by stimulating the

immune system against the toxin by use of inoculations

of pollen extract. These inoculations involve giving

increasing amounts of allergen extracts to reduce

symptoms on re-exposure to those particular allergens.

The procedure has been widely used since its inception

to treat immediate hypersensitivity disorders mediated

by allergen-specific IgE antibodies. These same basic

principles hold true today, more than 100 years later, for

current allergen immunotherapy.

Efficacy of Allergy Immunotherapy

Multiple studies have demonstrated the effectiveness of

allergen immunotherapy for the following conditions for

both children and adults:

2-25

• Allergic rhinitis

• Allergic conjunctivitis

• Allergic asthma

• Atopic dermatitis

• Insect allergy (Hymenoptera)

Each patient’s immunotherapy prescription is customized

and tailored to their particular allergic triggers, and

the administration schedule (buildup or maintenance)

may vary. The degree of effectiveness may vary for the

individual patient and is in part determined by whether

causative symptoms are predominantly allergic vs non-

allergic — patients may be more likely to have a limited

response if other causes are contributing to impairment.

Other symptomatic causes may include vasomotor

rhinitis, chronic infectious sinusitis, or anatomical

obstruction such as severe adenoidal hypertrophy.

In those whose symptoms are predominantly allergic

in nature, clinical improvement should occur within or

soon after the first year of treatment, and this benefit

may improve with continued treatment. The Allergen

Immunotherapy Practice Parameter third update

26

suggests that, “If clinical improvement is not apparent

after one year of maintenance therapy, possible

reasons for lack of efficacy should be evaluated. If

none are found, discontinuation of immunotherapy

should be considered, and other treatment options

should be pursued.” It has been observed that some

patients may experience a worsening of their asthma,

atopic dermatitis and allergic rhinitis or conjunctivitis

symptoms during treatment, especially during the first

few months of therapy.

Duration of Therapy

There is no consensus on when to discontinue

aeroallergen immunotherapy, but benefits are often

maintained for years after stopping therapy in some

individuals, and indefinitely in others. In grass-

pollen allergy, a three-year course of subcutaneous

immunotherapy gave prolonged relief of symptoms.

25

For many patients with stinging insect allergy, 3-5

years of treatment may be sufficient for sustained

effectiveness. However, patients who have experienced

life-threatening hymenoptera venom reactions should

be considered for life-long treatment.

Adverse Reactions

Allergen immunotherapy is usually well tolerated;

however, adverse reactions do occur, ranging in severity

from mild to severe. Allergen immunotherapy carries a

small but significant risk for life-threatening anaphylaxis

and has very rarely been associated with death.

Systemic reactions associated with immunotherapy may

have numerous causes. Risk factors include asthma and

injections administered during periods of symptom

exacerbations. Human error, due to administering

an incorrect dose or the wrong extract to a patient

is another risk factor. Delays in the administration of

epinephrine during a systemic reaction may increase

the risk of fatalities, which highlights the importance of

having trained personnel capable of identifying and

managing reactions.

Each patient should be evaluated prior to the

immunotherapy administration visit to determine

whether any recent health changes such as illness, acute

asthma symptoms, or new medication - which might

require modifying or withholding the immunotherapy

treatment. Clinical judgment is required when altering

the dose or schedule of administration. While allergen

immunotherapy extracts are relatively easy to prepare

and administer, initial and ongoing training will improve

the expertise of health care workers responsible for

mixing and administering immunotherapy and improve

the safety of the patients.

Subcutaneous allergen immunotherapy is not

indicated for patients with food allergies. Although

studies have demonstrated an increased tolerance to

peanut in patients who received subcutaneous peanut

immunotherapy,

27, 28

there was an unacceptably high

rate of systemic reactions (e.g., anaphylaxis) in most of

the patients during treatment.

28

4

II. ALLERGEN EXTRACTS

Allergen extracts used for immunotherapy are

manufactured following collection of raw material.

They consist of liquid solutions containing dissolved

allergenic proteins derived from pollens, dust mites,

animal dander and epithelia, molds, cockroach, and/or

venom. Extracts chosen for the treatment vials should be

clinically relevant for patients receiving treatment, based

on perennial and seasonal symptoms, the regional

presence of pollens and molds, and causative allergens

based on exposure.

The manufacturing process typically involves crushing

raw materials and “extracting” allergenic proteins by

addition of solvents capable of isolating the protein

from the solid raw material. This is followed by a

purification process, resulting in a liquid solution that is

stable under normal storage condition (approximately

4 degrees C or 39 degrees F), consisting of a mixture

of the diluents or solvents, additives, stabilizer /

preservative, allergenic proteins and other components

of the raw material.

Stock allergen extracts are licensed by the Center for

Biologics Evaluation and Research (CBER) within the

Food and Drug Administration (FDA) in the United

States. Commercially available stock extracts, supplied

by a handful of manufacturers, are used to mix

individual treatment sets and to prepare test panels.

Concentrated stock extracts are available in multiple

forms:

• Aqueous

• Glycerinated

• Lyophilized (freeze dried)

• Acetone precipitated

• Alum precipitated

Glycerinated stock extracts contain 50% glycerin by

definition. Other liquid-based extracts (i.e., saline,

buffers, liquid diluents) are referred to as aqueous

extracts.

Lyophilized extracts are aqueous extracts that

have been freeze-dried to increase stability during

storage and shipping. When they are reconstituted in

accordance with package insert instructions with an

appropriate diluent just prior to use, they form aqueous

extracts. Hymenoptera venom extracts are typically

available in lyophilized form.

Acetone-precipitated extracts are liquid extracts that

include a processing step of acetone precipitation to

create a high concentration stock solution. The acetone

is used to precipitate proteins from liquid into a solid

form, which is then re-dissolved in a diluent to make the

final highly concentrated stock solution.

Alum-precipitated extracts are liquid extracts that

include a processing step involving the addition of

aluminum hydroxide, or alum. Allergenic proteins attach

to the alum and form complexes that serve as depot

when injected into skin, slowing the release of allergens

on injection. The slow-release alum-allergen complexes

may allow for larger doses of extract to be given at less-

frequent intervals and a more rapid buildup to higher

maintenance doses with reduced incidence of systemic

reactions. Local reactions at the site of alum-precipitated

extract injection may be immediate or delayed. Delayed

reactions may start several hours later, with local edema,

erythema (redness), itching and pain.

The cloudy appearance of the extract, which may

contain visible precipitate, is normal and different

than typical aqueous extracts. These extracts require

shaking before use. Furthermore, only certain diluents

can be used to dilute these extracts. The package

insert from stock antigens may be referenced to

identify the appropriate diluents for use with alum-

precipitated extracts. For example, one manufacturer

requires the use of phenol saline diluent for all 10-

fold dilution vials. Ten percent glycerol-saline and

human serum albumin (HSA) diluent usually cannot

be used for alum-precipitated prescriptions because

of interference with the aluminum hydroxide-antigen

absorbed complex. The slow release described above

makes these less effective in skin testing and are thus

used for treatment only.

Diluents are solutions used to keep the allergens in

suspension. They are used to reconstitute lyophilized

extracts, to dilute extracts for diagnostic use, to dilute

vials in treatment sets and to fill maintenance vials to

final volume after addition of stock allergen quantities.

Commonly used diluents:

• Glycerin (e.g., 50% glycerin ± phenol)

• Phenol saline (e.g., 0.4% phenol, saline)

• HSA (e.g., 0.03% HSA, 0.4% phenol, saline)

Each diluent has advantages and disadvantages related

to preservation of extract potency and sterility. These

additives are discussed in further detail in this chapter’s

discussion of extract stability.

Standardized Subcutaneous Allergen Extracts

Standardized subcutaneous allergen extracts in the

United States include:

5

• Cat hair and pelt (BAU/mL potency labeling based

on Fel d 1 content)

• Dust mite (Dermatophagoides pteronyssinus and D.

farinae; potency in AU/ML)

• Short ragweed (potency in AU/mL or wt/vol with

lot-specific Amb a 1 concentration)

• Grass (Bermuda, Kentucky bluegrass, perennial

rye, orchard, timothy, meadow fescue, red top and

sweet vernal; potency in BAU/mL)

• Hymenoptera venoms (yellow jacket, honey bee,

wasp, yellow hornet, white-faced hornet, and mixed

vespids; potency in µg/mL)

These extracts have been standardized with the intent

of ensuring consistency of allergy content and potency

between manufacturers and lots made from the same

manufacturer. Standardization is based on intradermal

skin test responses in allergic individuals. Specifically,

reference standards from the FDA CBER are obtained

for standardized allergen extracts by identifying

concentrations that reproducibly produce erythema

with a sum of perpendicular long axes of 50 mm, or

ID

50

EAL.

29

These reference standards are then used by

manufacturers to ensure that the allergen content of

each new lot falls within specified ranges for potency

labeling. Blood tests (immunoassays) have been

developed that correlate allergenic protein content to

skin test reactions and, in some cases, treatment results.

These include measurement of major allergen content

(cat hair Fel d 1 and ragweed Amb a1), total protein/

hyaluronidase/phospholipase content (Hymenoptera

venom) and other assays (pooled sera immunoassay

inhibition activity).

Units of potency applied to standardized extracts vary

and include bioequivalent allergy unit/mL (BAU/mL),

allergy unit/mL (AU/mL), and microgram protein/mL

(µg/mL). Some allergen extract labels also include the

concentration of major allergenic proteins in µg/mL.

Since the standardization is based on allergen content

falling within a specified range, it still remains possible

for actual allergenic protein content to vary several-fold

for the same potency label. Only a few allergen extracts

have been standardized to date (see Appendix 1 for

effective dosing ranges).

III. ALLERGEN EXTRACT MIXING STANDARDS, QUALIFICATIONS, AND COMPETENCIES

While it would be ideal for allergen mixing personnel

to have a single guideline to refer to, there are

currently two documents that all personnel who mix

allergen extracts must utilize. The most widely adopted

recommendations in the United States for all aspects

of allergen immunotherapy are contained in the 2011

publication, “Allergen immunotherapy: A practice

parameter third update.”

26

This joint effort by experts

from the College and AAAAI and focuses on evidence-

based recommendations to optimize immunotherapy

efficacy and safety. All health care providers involved

in immunotherapy preparation and administration

should be oriented to the contents of this practice

parameter, which contains practical clinical information

and sample forms. In this document, TABLE VII. Allergen

Immunotherapy extract preparation guidelines may be

found on page S36.

The second publication, USP Chapter <797>, focuses

on maintaining sterility in the compounding of

allergen extracts, including requirements for training

and testing of personnel. USP 797 sets standards for

preparing sterile preparations, including allergen extract

preparation. The requirements for compounding of

allergenic extracts are laid out in USP 797 Section 21.

Required qualifications of mixing personnel may be

found in Section 21 on pages 30 — 31, and facilities

requirements found on page 31. These standards,

though extensive and more rigorous than earlier USP

797 requirements, remain less rigorous than standards

required for typical sterile drug compounding in

pharmacies.

Practitioner Qualifications

There are many positions within the allergy immunology

office that have an impact on the safety of allergen

immunotherapy. These include:

1. Supervising physician: responsible for overseeing

and ensuring the competency of staff preparing and

administering allergen immunotherapy.

2. Designated supervisor: person with training

and expertise in allergen immunotherapy who is

responsible for ensuring that personnel who will

be preparing allergen immunotherapy are trained,

evaluated and supervised.

3. Compounding personnel: those who mix allergenic

extracts. Before beginning to independently prepare

6

allergenic extracts, all compounding personnel must

complete training and demonstrate knowledge of

principles and skills for sterile compounding.

4. Shot personnel: those who administer allergy

immunotherapy injections. State laws may differ with

regard to approved personnel. Knowledge of how to

appropriately administer immunotherapy extracts is

critical for patient safety, making personnel training

a requirement. Recognizing the signs and symptoms

of anaphylaxis are also critical for any facility involved

in the delivery of allergen immunotherapy. Efforts

at standardization, including color coding vials,

standardizing labeling and documentation are

intended to decrease the risk of dosing errors for any

facility administering immunotherapy.

Training, Competency Assessment and Documentation

Training of personnel involved in the mixing of

allergen extracts and/or administration of allergen

immunotherapy is a critical requirement for safety

and efficacy. Content of the training should include

core cognitive knowledge as well as demonstration of

procedure performance competency.

There are a variety of ways to receive training in allergen

immunotherapy preparation and administration.

Formats may vary from lectures to hands-on training to

meet the needs of each learner and include:

• On-the-job training from a qualified co-worker or

supervisor.

• Workshops and seminars offered at the College’s

Annual Meeting.

• Educational offerings via the College Learning

Connection, including the Allergen Extract

Preparation Quiz.

• Manuals from allergen extract manufacturers.

• Allergen Immunotherapy: A Practice Parameter

Third Update and other journal articles.

• Allergen Extract Mixing Toolkit.

Suggested qualifications of extract preparation

personnel based on the Practice Parameter on Allergen

Immunotherapy and applicable USP Chapter <797>

standards include ability to:

• Demonstrate understanding of appropriate hand

hygiene, garbing, surface disinfection, aseptic

technique, achieving and/or maintaining sterility,

calculating/measuring/mixing, use of equipment

and documentation.

• Pass a written test on aseptic technique and extract

preparation.

• Annually pass a media-fill or equivalent test

verifying use of aseptic technique.

• Annually pass a gloved fingertip-thumb sampling

test verifying hand sterility after passing three initial

tests.

• Be reinstructed and reevaluated if failing the written

test, media-fill test or gloved fingertip-thumb

sampling test.

To be compliant with USP Chapter 797 Section 21

requirements, allergist offices must keep records

of training, assessment results, evaluations and

qualifications for all compounding personnel, including

any corrective actions following assessments and

evaluations. Appendix 2 contains a sample document

for assessing and documenting competency of

personnel in the preparation of allergen immunotherapy

treatment sets. It is adapted from competency elements

for allergy technicians / nursing personnel at the U.S.

Army Centralized Allergen Extract Laboratory. These

competency elements are based on recommendations

of the Joint Commission on Accreditation of Hospital

Organizations, or JCAHO, requirements. As with all

sample forms, this serves as an example — each mixing

center should develop site-specific standard operating

procedures and competency standards, with forms that

meet the needs of their specific practice.

7

IV. ALLERGEN IMMUNOTHERAPY PRESCRIPTIONS

Allergen immunotherapy prescriptions specify the

precise contents of individual treatment sets for

patients receiving immunotherapy. They may be written

or electronic but should contain several essential

elements. Standardization of content will promote

proper preparation, minimize risk for errors in allergy

shot administration and facilitate patient transfers of

care. Employing the prescribing principles that follow

will result in a product that is safe and effective, and can

ensure maintenance of expected potency through the

expiration date. Each prescription / immunotherapy

record should contain:

• Two patient identifiers (i.e., Name and Date of Birth

or Medical Record Number)

• Patient contact information

• Name of prescriber

• Date of prescription

• Name, concentration and volume for each allergen

• Name and volume of diluents

• Schedule for administration (including adjustments

for interruptions and reactions)

All prescriptions should be reviewed for accuracy prior

to preparation.

Optimal mixing of allergens to create an individual

patient treatment set should be based on:

• Use of relevant allergens for each patient

• Dosing of allergen extracts within minimum

effective dose ranges (Appendix 1)

• Avoiding combining extracts that may adversely

affect overall potency

° Separate high protease extracts (mold, cockroach)

from pollens

32

° Avoid mixing venom extracts with aeroallergen

extracts.

26

Selection and adjustment of doses

using knowledge of cross-reactivity

Mixing high-protease extracts with most other

aeroallergens will result in a loss of potency that can

affect immunotherapy efficacy. Aeroallergens with

known high cross-reactivity allow prescribers to treat

with fewer allergens while providing coverage for

a large number of related allergens. For example,

treatment with one or two northern pasture grass

allergen extracts should be sufficient to provide benefit

for the more than 10 cross-reactive northern grass

species.

34

Figure 1 is an example of a completed allergen

immunotherapy prescription. In this example, the

desired maintenance dose for cat was 2000 BAU for a

0.5-mL injected dose from a 5-mL maintenance vial (a

blank form is available in the Appendix).

2 mL of standardized cat extract (10,000 BAU/

mL) is needed to achieve a final maintenance vial

concentration of 4000 BAU/mL and an injection dose of

2000 BAU. To do this use the step-by-step calculations

below.

Step-by-step calculations are as follows:

• Maintenance vial concentration of cat = injection

dose/injection volume = 2000 BAU/0.5 mL = 4000

BAU/mL

• V1 x C1 = V2 x C2 (maintenance vial volume x

maintenance vial concentration = stock volume x

stock concentration)

• 5mL x 4000 BAU/mL = V2 x 10,000 BAU/mL [V2 =

stock volume = (5 x 4K)/10K = 2 mL]

• Repeat for each antigen in vial

• Total antigen volume = cat 2 mL + D. farinae 0.5 mL

+ D. pteronyssinus 0.5 mL + timothy 0.4 mL + short

ragweed 0.2 mL

• Diluent volume = (maintenance vial volume) – (sum

antigen volumes) = 5 mL – 3.6 mL = 1.4 mL

• Final maintenance vial contents:

Antigen Concentration Dose

Cat 4000 BAU/ml 2000 BAU

Ragweed 17.5 microgram/mL 8.75 microgram/

mL Amb A 1

D. farina 1000 AU/mL 500 AU

D. pteronyssinus 1000 AU/mL 500 AU

8

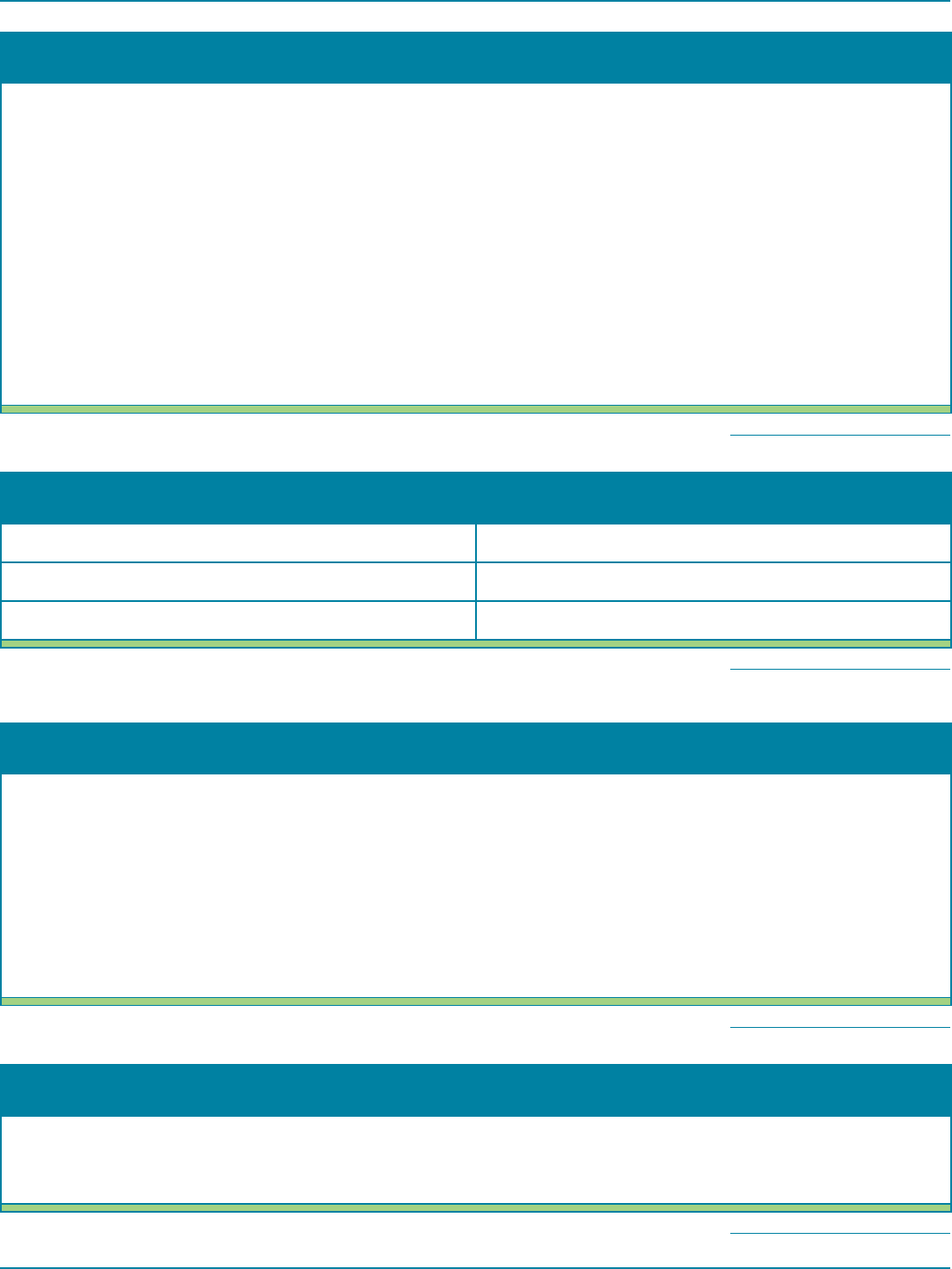

FIGURE 1. EXAMPLE — ALLERGEN IMMUNOTHERAPY EXTRACT PRESCRIPTION (blank form available in Appendix)

Patient Name: Mary Wheeze Prescribing Physician: Dr. Allergist

Patient Number: Address:

Birth Date: Telephone:

Telephone: Fax:

Antigen

Number

Extract Name

Allergen or Diluent

(Common name of

Genus/species)**

Concentration and Type

Manufacturer’s Extract

(AU, BAU, W/V, PNU)/

(50%, G, Aq, Ly, AP)

Volume of

Manufacturer’s

Extract to Add

Extract

Manufacturer

Lot

Number

Expiration

Date

1

Short Ragweed 1:10 w/v G

(350 mcg Amb a1

0.25 ml Greer 11111 12/25/2021

2

D. farina 10,000 AU/ml G 0.5 ml Allermed 22222 12/26/2021

3

D. Pteronyssinus 10,000 AU/ml G 0.5 ml Antigen labs 33333 2/7/2022

4

Cat 10,000 BAU/ml G 2 ml Hollister-Stier 44444 12/5/2021

5

Timothy Grass 100,000 BAU/ml G 0.4 ml ALK 55555 12/3/2021

6

7

8

9

10

Diluent

HAS 1.35 ml ALK 66666 12/5/2021

Total

Volume

**Components of mixes listed on a separate sheet.

By Use Date ____________________________________________________________________________________________________________

Storage Requirements ___________________________________________________________________________________________________

Results of Quality Control (e.g. visual inspections, second verification of questions) _____________________________________________

Allergen Extract Name:

R, Dm, C, G

Bottle Name Abbreviations

Tree: T Mold: M

Grass: G Cat: C

Weed: W Dog: D

Ragweed: R Cockroach: CR

Mixture: Mx Dust Mite: Dm

Specific Instructions:

Prescribing Physician’s Signature Date

Volume to add = Maintenance Concentration x Total Volume

Conc. of Manufacturer’s Extract

Maintenance concentration and subsequent dilutions

reported as volume/volume (v/v) dilutions with maintenance

concentrations=1:1 v/v

BAU=Bioequivalent Allergy Unit, AU=Allergy Unit

PNY=Protein Nitrogen Unit

W/V=Weight per Volume Ratio

G=50% Glycerinated

Aq=Aqueous, Ly=Lyophilized

AP=Alum precipitated, AcP=Acetone precipitated

Maintenance Concentrate Prescription Form

Prepared by: Great Nurse Date Prepared: 11/01/2019 Time: 10 a.m.

Dates of subsequent dilutions from maintenance concentration with expirations dates:

Vial __________ From Vial __________ on ____/____/____ Expiration date: ____/____/____

Vial __________ From Vial __________ on ____/____/____ Expiration date: ____/____/____

Vial __________ From Vial __________ on ____/____/____ Expiration date: ____/____/____

Vial __________ From Vial __________ on ____/____/____ Expiration date: ____/____/____

*Adapted from Allergen immunotherapy: A practice parameter second update. J Allergy Clin Immunol 2007;120: S77.

9

V. COLOR CODING, LABELS AND BEYOND USE DATES

The Allergen Immunotherapy Practice Parameters

and Joint Commission National Patient Safety goals

emphasize the need for clear and consistent labeling.

Standardization of allergen immunotherapy label

contents and vial coding helps improve communication

between care providers and patients, and likely prevent

errors in extract administration.

Each patient’s treatment vial label should contain at

minimum:

• Patient name, plus a second identifier (e.g., date of

birth)

• Concentration in vol/vol

• Color code and vial number, per the Practice

Parameters

26

• Expiration or beyond use date (BUD)

• Storage conditions

Immunotherapy treatment vial concentrations are

now labeled in vol/vol, with 1:1 vol/vol representing

the maintenance concentrate. Alternatively, the vial

concentration can be labeled in actual units (e.g., 1000

BAU, 100 BAU), but this system may be complicated

if allergens with different potency units are used (e.g.,

wt/vol, BAU, AU or PNU) and these differences make

it difficult to interpret the vial label. All vials in the

treatment set should be numbered and/or color coded

in the following manner as outlined in the most recent

practice parameters (Figure 2, page S44):

26

RED Maintenance 1:1 vol/vol #1

concentrate

YELLOW 10-fold dilution 1:10 vol/vol #2

BLUE 100-fold dilution 1:100 vol/vol #3

GREEN 1000-fold dilution 1:1000 vol/vol #4

SILVER 10,000-fold dilution 1:10,000 vol/vol #5

The highest concentration should be labeled #1 and

the next 10-fold dilution (i.e., yellow vial) would be

labeled #2, and so forth. This system was designed to

eliminate variation from patient to patient that occurs

when labeling vials of higher concentrations with larger

numbers. This practice resulted in patients often having

a different number on their maintenance vial that was

based on the total number of dilutions prepared.

Vial expiration dates should follow the manufacturer’s

recommendations. The expiration date for a treatment

vial should be no later than the earliest expiration

date recommended for any stock allergen or diluent

contained in each prescription vial. Less-concentrated

extracts are more sensitive to temperature and might

not maintain potency until the listed expiration date;

1:10 to 1:200 dilutions of stock extracts are generally

stable for at least 12 months. This usually includes at

least the patient’s red maintenance treatment vial and

the 1:10 vol/vol, or yellow, vial. Expiration dates for

venom extracts may be shorter; perhaps this is due

to the use of diluents with low levels of glycerin. The

venom extract package inserts provide guidelines for

expiration dates for the different dilutions.

Expiration dating periods for allergen extract products

are regulated by the FDA. Even under ideal refrigerated

conditions, some loss of potency occurs over time.

The potency and stability of these products are not

guaranteed beyond their labeled expiration date.

Nonstandard extract products are assigned expiration

dates in accordance with FDA regulations (21 CFR,

Section 610.53) with regard to whether products are

glycerinated or non-glycerinated. A total of six years

from the time of extraction is allotted to 50% glycerin

bulk extracts. This six-year period is divided into a

maximum of three years for manufacturer storage

and three years for shipped vial expiration dating.

Non-glycerinated products are allowed only a total of

three years or half the expiration the time allotted for

glycerinated extracts —18 months for manufacturer

storage and 18 months for shipped expiration dating.

Following is an example of expiration dates for

diagnostic and treatment sets prepared by the

U.S. Army Centralized Allergen Extract Laboratory,

which are based on stock concentrate manufacturer

recommendations from its suppliers.

10

Diagnostic Products Expiration Date*

Prick Test Materials 1 Year

ID Test Materials 6 Months

Immunotherapy Treatment Sets

1:10 W/V-1:5000 W/V 1 Year

1:50,000 W/V and weaker 3-6 Months**

1000 PNU/ml — 20,000 PNU/ml 1 Year

<1000 PNU/ml 3-6 Months**

500 AU/ml and Stronger 1 Year

< 500 AU/ml 3-6 months**

1000 BAU/ml and Stronger 1 Year

< 1000 BAU/ml 3-6 months**

*Use earliest of stock extract label expiration date or date

below

**The stability of lower extract concentrations (e.g.,

1:1000 and 1:10,000 vol/vol) has not been extensively

studied. Loss of potency in these lower concentrations

may be due to absorption of the allergenic proteins to

the glass wall. Human serum albumin may have a more

protective effect against this cause of loss of potency

than other diluents such as normal saline.

Reconstituted Venom Freeze Dried Preparations

100mcg/ml 6 or 12 months*

1-10mcg/ml 1 month

0.1mcg/ml 14 days

<0.1mcg/ml 24 hours

*Varies with company. Guidelines for dilution expiration

dating are in the extract package insert

VI. MIXING INDIVIDUAL PATIENT ALLERGEN EXTRACT TREATMENT SETS

General Principles

Every clinic should develop a specific standard

operating procedure (SOP) document or manual to

ensure standardization and safe practices of allergen

extract mixing. Responsible providers developing the

procedures should consult stock extract manufacturer

recommendations and the most recent Allergen

Immunotherapy Practice Parameter Update to

incorporate the most up-to-date recommendations. USP

797 requirements must also be reviewed and followed.

The mixing of antigens in a syringe is not recommended

because of the potential for cross-contamination of

extracts.

Initial Preparation

1) Designate a dedicated allergenic extracts

compounding area (AECA) with a visible perimeter

that establishes the boundaries of the AECA, and

meets the following conditions (as required by USP

797):

• Access restricted to authorized personnel.

• No other activity permitted during compounding.

• All surfaces are cleanable and kept clean.

• Carpet is not allowed.

• Surfaces must be impervious to cleaning and

sanitizing agents; must be smooth, non-shedding,

and free of cracks or crevices.

• Overhangs should be avoided or must be easily

cleaned.

• Work areas must be well lit, temperature and

humidity controlled for comfort of compounding

personnel.

• Work surface must be cleaned and disinfected

before and after each compounding session;

disinfected between each new set, as well as at the

time of any spill or contamination.

• During compounding, at that time.

2) Before beginning compounding, ensure your

personnel performs hand hygiene and garbing

procedures (that should include the minimum

requirements noted below) and according to your

clinic’s SOPs.

• Low-lint garment with sleeves that fit snugly around

the wrists and that is enclosed at the neck (e.g.,

gowns or coveralls);

• Low-lint, disposable covers for head that cover the

hair and ears and, if applicable, disposable cover

for facial hair;

• Face mask; and

• Sterile powder-free gloves.

3) Ensure compounding personnel rub sterile 70% IPA

onto all surfaces of the gloves and allow them to dry

11

thoroughly throughout the compounding process.

4) Clearly identify expiration dating standards for your

clinic.

5) Become familiar with stock allergen ordering and

storage procedures.

6) Orient personnel to stock allergen extracts,

refrigerator storage designated mixing location,

mixing equipment, prescriptions, documentation and

packaging.

7) Ensure appropriate personnel are trained on SOP and

safety measures and have the required competencies

to independently mix allergen extracts.

Pre-mixing Preparation

1) Verify that a supervising physician is present in the

same building as the mixing location(s).

2) Cleanse and maintain an aseptic work environment

using 70% isopropanol as recommended in USP 797

Allergen Extract Preparation

3) Prepare vial labels in accordance with prescription

and verify accuracy of:

• Name and second identifier

• Concentration

• By use date (BUD) is consistent with clinic

procedures and source antigens.

4) Verify color-coded vials with designated

concentration

Labels may be applied after mixing. For example, the

label for the empty maintenance concentrate (red) vial

(or all vials) can be left off until all contents are injected

into the vial to improve visibility during checks for

impurities, final volume, color comparison of dilution

series, and better aseptic technique.

Example Allergen Extract Mixing Step-By-Step

Procedures

This sample set of procedures provides general guide-

lines that can be used as a starting point to develop

procedures that best fit a specific clinic/facility needs.

Mixing the Maintenance (Red) Vial (see Appendix 3)

1) Select new empty sterile vials (usually 5, 8 or 10 mL)

for each vial in patient’s treatment set, using color

codes to line up strongest (maintenance/red) to most

dilute.

2) Select stock extract for each antigen contained in the

prescription, and stock diluents.

• Check stock antigens for turbidity/particulate

matter. If present, consult package insert or

manufacturer guidelines including possible

recommendations for resuspension or filtering.

• For prolonged mixing sessions, return unused

stock extracts to refrigerator or cooling tray (2º-8ºC)

between prescriptions or during extended breaks.

3) Place a new syringe by each stock antigen vial and

the diluent.

• A separate syringe is used for each antigen and

diluent.

• Label each syringe (i.e. abbreviation for antigen or

diluents)

• Avoid storing stock extracts in a syringe for

extended periods due to risk of potency loss and

misidentification.

4) Document lot number and manufacturer for each

antigen

5) Ensure that label expiration date does not exceed

earliest stock vial extract or diluent expiration date.

6) Perform Hand Hygiene per USP 797 standards.

• Remove visible debris from underneath fingernails

under warm running water using a disposable nail

cleaner

• Wash hands and forearms up to the elbows with

soap and water for at least 30 seconds

• Dry hands and forearms to the elbows completely

with low-lint disposable towels or wipers.

7) Personnel garbing requirements

• Don hair and facial hair covers, gowns and face

masks

• Use alcohol- based surgical hand scrub prior to

gloving.

• Don powder-free sterile gloves compatible with

70% isopropyl alcohol.

8) Disinfect gloves with isopropyl alcohol and allow

them to dry before mixing (and intermittently for

lengthy mixing).

9) Wipe vials and/or ampules with 70% isopropyl

alcohol and allow to dry.

10) Maintain aseptic technique by minimizing contact

with secretions, skin, glove fingertips and other

potential sources of contamination during the

mixing process.

12

11) Draw the correct amount of each antigen and the

diluent into the syringe, and place each syringe by

the respective stock antigen vial.

12) Verify drawn doses are correct volume and antigen.

(Quality checkpoint opportunity: have a co-worker

verify, if available. This is a best practice, but this is

not required by USP 797.)

13) Sequentially inject contents of antigens into the

maintenance concentrate (red) vial.

• Empty syringes should be discarded immediately

into an appropriate sharps disposal container

• If the sterile maintenance vial is not a vacuum vial,

an equal volume of air may need to be withdrawn

prior to injecting stock extract volumes

14) After mixing is complete, conduct final quality

assurance check (best practice would include mixer

and trained co-worker), including:

• Solution color check.

• Label check.

• Vial color-code check.

• Liquid turbidity, precipitate and consistency check.

• Vial physical integrity (leaks, cracks and so on)

check.

15) If applicable, package treatment set for transport or

shipping.

16) Document preparation details according to clinic-

specific procedures on prescription or preparation

form and in mixing log as follows:

• Name of preparer and date prepared.

• Stock allergen extract manufacturer, lot number

and beyond-use or expiration date.

• Mixing log, to be maintained in the unlikely event

of a stock allergen recall or for extract or adverse-

event troubleshooting.

Notes Regarding Alum-Precipitated Extracts

• Diluent: Alum-precipitated extracts generally

require phenol saline diluent for all 10-fold dilution

vials. Ten percent glycerol-saline or HSA diluent

cannot be used for alum- precipitated prescriptions

as it interferes with the aluminum hydroxide-

antigen absorbed complex.

• For alum-precipitated extract treatment vials,

consider applying a small “shake well” label, as

the alum-precipitated antigens are very viscous

in nature. Precipitated alum- antigen complex will

settle to the bottom of the vial.

• Unlike aqueous and glycerinated extracts that

generally do not lose potency with filtering, large

antigen-alum complexes may be lost during the

filtering process, with the result being a result

in loss of potency. Therefore, do not filter alum-

precipitated extracts.

Preparing Serial 10-Fold Dilutions

• Serial 10-fold dilutions are prepared to complete a

patient’s initial allergen immunotherapy treatment

vial set. Dilutions are made by serial dilution

(taking from a parent vial and placing into a new

vial prefilled with diluent to create a 10-fold dilution

1/10 the amount of allergen contained in the

parent vial). This newly diluted vial then becomes

the “new” parent vial, and dilutions are repeated

until the desired number of 10-fold dilutions is

achieved.

• The volume used to make serial dilutions from

parent vials depends on both the desired dilution

(10-fold in this case) and the final volume.

Typical treatment set vials are 2, 5, 8 or 10 mL.

Treatment set vials are available with original or

snap-on colored caps to create sets according to

the recommended color scheme. Vials also are

available empty or prefilled with diluents suitable

for intradermal or subcutaneous administration.

Prefilled volumes correspond to the amount of

diluent needed to make a 10-fold dilution.

• To determine how much should be taken from the

parent vial for a 10-fold dilution for final volume

X, divide X by ten (i.e., for a 10 ml vial: 10ml/10

= 1 ml). Then calculate the amount of diluent

needed by subtracting this X/10 volume from the

final volume X (i.e. 10 ml – 1 ml = 9 ml). The final

concentration of the diluted vial is 1/10th that of the

parent vial.

Sample preparation of a 5-mL SERIAL 10-Fold Dilution

Verify that the labeling and order (color coded, label

concentration) for vials are correct.

1) Ensure the maintenance vial is mixed by inverting or

rolling.

2) Using a fresh syringe and aseptic technique, remove

0.5 mL from the mixed 5-mL maintenance concentrate

red or 1:1 vol/vol vial.

3) Using aseptic technique, inject this 0.5 mL form

the maintenance vial into the 4.5-mL prefilled (10%

glycerol-saline or HSA) yellow or 1:10 vol/vol vial.

This vial will consist of 5mL of a 10-fold dilution of the

maintenance concentration vial.

4) Ensure the newly made 10-fold diluted (yellow) vial is

mixed by inverting or rolling.

13

5) Subsequent 10-fold dilutions are done in the same

manner for the remainder of the vials in the treatment

set (0.5 mL into 4.5 mL of the 10-fold, labeled 10%

glycerol-saline prefilled vial):

1. 0.5 mL from yellow 1:10 vol/vol into a 4.5 mL

diluent-filled blue 1:100 vol/vol vial

2. 0.5 mL from blue 1:100 vol/vol into 4.5 mL diluent-

filled green 1:1000 vol/vol vial

3. 0.5 mL from green 1:1000 vol/vol into 4.5 mL

diluent-filled silver 1:10,000 vol/vol vial

4. And so on for additional more dilute (silver) vials

5. Whereas using a fresh syringe for each dilution

transfer is often preferred, use of the same syringe

for serial dilution transfers is an alternative if a

“mix/rinse” step is included. A mix/rinse step

consists of pulling up a syringe volume (1mL for

a 1-mL syringe) from the vial just injected and re-

injected into the same vial without removing the

syringe. This is often repeated (i.e., for a total of

three times) prior to pulling up the final volume for

the transfer to the next dilute vial. (Reminder: This

is for making dilutions only. Do not reuse syringes

or mix/rinse between different stock solutions

when mixing the initial maintenance vial.)

Table 1. Calculations for making Extract Dilutions

Table II. Calculations for making Extract Dilutions* (from Practice Parameters page S10)

All dilutions can be calculated by using the following formula:

V1 X C1 = V2 X C2,

where

V1 = Final volume you want to prepare

C1 = Concentration (wt/vol or PNU) of extract you want to prepare

V2 = Volume of extract you will need for dilution

C2 = Concentration of extract you will use.

Example: Solve for V2; (V1 X C1)/C2 = V2.

To determine the concentration of an item in a mixture:

1. determine which formula you need to use;

2. choose the numbers/fractions that will be inserted into the formula for V1, C1, V2, and C2;

3. change all wt/vol fractions to a decimal number and insert into the formula (see below); and

4. multiply first and then divide to get the answer.

To express concentration as a percentage:

1:10 wt/vol 1/10 = 0.1 X 100 = 10% solution

1:20 wt/vol 1/20 = 0.05 X 100 = 5% solution

1:40 wt/vol 1/40 = 0.025 X 100 = 2.5% solution

Example:

V1 = 5 mL Final volume you want to prepare

C1 = 1:200 Concentration you want to prepare

V2 = Unknown Volume of extract you will need for dilution

C2 = 1:10 Concentration of extract you will use

Add values into formula:

V1 X C1 = V2 X C2 5 X (1/200) = V2 X (1/10)

5 X (0.005) = V2 X (0.1)

V2 = (V1 X C1)/C2 V2 = 0.025/0.1 = 0.25

To determine amount of diluent needed:

V1 — V2 5 – 0.25 = 4.75 mL

Adapted from the Greer Allergy Compendium. Lenoir (NC): Greer Laboratories: 2005. p. 71. Permission provided by Robert Esch, PhD.

14

Allergen Extract Treatment Set Preparation Hints

1) Do not mix prescriptions for more than one patient at

a time.

2) Train multiple qualified personnel in allergen extract

preparation in case of absences and for participation

in quality checks.

3) Avoid putting hand lotion on before the

compounding of allergen extract and skin test

antigens. Lotion tends to harbor bacteria.

4) Regularly review operating procedures for opportunities

to make the process safer and more efficient.

5) Establish a regular inventory check.

• Identify stock allergen extracts, diluents and mixing

supplies in need of reordering

• Check for expiring stock allergen extracts, diluents

and mixing supplies

6) Return antigen stock trays to the refrigerator when

away from the compounding area for an extended

period of time.

7) Minimize distractions during extract preparation.

8) Stock refrigerators are not to be used for food or

drink storage.

9) Particulates and precipitates suspended in an extract

solution are not uncommon.

• These particulates and precipitates often do not

cause any significant loss in potency. Consult

manufacturer recommendations in package insert

or bulletins for additional information.

• Attempted re-suspension by agitation (shaking

or rolling) may be indicated in accordance with

the package insert and your clinic operating

procedures.

10) Diluted allergen immunotherapy vials (yellow,

blue, green, and silver) should not made by pulling

directly from a manufacturer’s concentrated stock

vial extract.

• The primary reason for this is the potential for error

that is increased progressively with each dilution. For

dilute vials, a very small amount of allergen would

need to be pulled from the stock extract vial, and it is

virtually impossible to achieve the precision needed

for the most dilute vials.

• Thus, a dilution vial prepared by this method

may contain inaccurate amounts of extract and

potentially increase the risk of adverse events

during vial transitions within the buildup phase.

Additional Quality Assurance Checks

Additional quality assurance checks before allergen

extract shipping and use ideally are confirmed by a co-

worker. Vials should be inspected for:

• Vial serial color dilution that matches label

concentration and vial color coding

• Vial integrity (no cracks, leaks, and so on)

• Vial content (particulate matter, fill volume, and so

on)

• Label accuracy – “five rights” as described below

Verify that the label contains the 5 rights

• Right name,

• Right content (allergens),

• Right concentration, right alphanumeric number

in the right order with most concentrated = 1 (if

numbers used),

• Right expiration date (dilute vials may have earlier

expiration dates than more concentrated vials).

• Right color, a solution color check for each vial

should be conducted.

The solution in the maintenance concentrate vial should

be the darkest in color, and vials should be lighter in

color with each 10-fold dilution. The weakest strength

vial should contain the lightest-colored solution. When

using color-coded vials, a vial color code check should

be performed. Vials in the treatment set should be

arranged in order (red/maintenance, yellow, blue,

green and silver). For each color-coded vial, label

concentration, in vol/vol, or number should match what

is recommended in the Practice Parameters for the color

code (see Tables XI and XII from Practice Parameters

26

).

All vials should also undergo a content check. Vials

should be filled to the expected volume. Solutions

within each vial should be inspected for the presence of

particulate or solid materials and cloudiness. If found,

vials may be contaminated or contain precipitated

raw allergen extract contents. Contamination may

be bacterial or other microbial source, but may

also be a result of introduced solid materials like

the rare occurrence of vial stopper fragments from

manufacturing or repeated puncturing. Any abnormal

finding during any of these checks should be followed

by an investigation for the cause and, in most instances,

starting over and remixing that patient’s vial set.

15

Table 2. Preparing Allergen Extract Treatment Sets (2 antigens, 0.5 ml stock of each)

Dilution label/

color

Label Conc

vol/vol

Extract

added

Diluent

added

Ragweed

w/v

Grass

BAU/ml

stock extract 1:10 100,000

1 (red/maint) 1:1 0.5 mL of each stock 4.0 mL 1:100 10,000

2 (yellow) 1:10 0.5 mL red (1) vial 4.5 mL 1:1,000 1,000

3 (blue) 1:100 0.5 mL yellow (2) vial 4.5 mL 1:10.000 100

4 (green) 1:1,000 0.5 mL blue (3) vial 4.5 mL 1:100,000 10

5 (silver) 1:10,000 0.5 mL green (4) vial 4.5 mL 1:1,000,000 1

*Treatment set for maintenance concentrate with 0.5 ml stock conc. grass (100,000 BAU/ml) & ragweed (1:10 w/v) in 5ml

VII. STINGING INSECT ALLERGEN EXTRACT PREPARATION

Extracts are available for five winged Hymenoptera

species at a concentration of 100 µg/mL: honey bee,

wasp, yellow jacket, yellow hornet and white-faced

hornet. The last three (yellow jacket, yellow hornet

and white-faced hornet) are closely related members

of the Vespidae family and have also been combined

in a single “mixed vespid” extract at a reconstituted

concentration of 300 µg/mL. Lyophilized or freeze-

dried stinging insect venom extracts are available

commercially for diagnostic testing and patient

treatment. These extracts are composed of venom

isolated directly from dissected venom sacs.

Previously manufactured extracts using whole insect

body as opposed to concentrated venom proved

not to be as effective as extracts made from venom.

35

Accordingly, handling of these extracts is limited to

reconstitution and dilution. The same principles and

requirements for labeling apply with the exception of

number/color coding and use of vol/vol concentration.

The concentration of these extracts and all dilutions is

expressed in µg/mL. Reconstitution and dilution of all

insect venom extracts is most commonly performed with

HSA (HSA/phenol) diluent.

Extracts are also available for imported fire ant

Hymenoptera species. Two fire ant species, Solenopsis

richteri and S. invicta, are commercially available as

individual extracts for testing or treatment, or as a

fire ant mix containing both species. Fire ant extracts

are made from whole fire ant bodies. Fire ant venom

extracts are being investigated for clinical use but

require a significant amount of time and resources for

mass production. Fire ant stock concentrate extracts

typically are available as non-standardized glycerinated

extracts in wt/vol concentrations (i.e., 1:20 wt/vol). The

Practice Parameters for Insect Allergy contains survey

data on common fire ant maintenance doses ranging

from 0.5 mL of 1:100 wt/vol to 0.5 mL of 1:10 wt/vol

maintenance concentrate, with most using 0.5 mL of a

1:100 wt/vol maintenance concentrate.

36

Insect venom (and fire ant) extracts generally should

not be mixed with other venom or aeroallergen extracts

for either testing or treatment because of the lack of

sufficient stability, safety and efficacy studies to support

mixing. The only FDA-approved mixture is commercially

available mixed vespid extract containing 100 µg/mL of

each of the three common vespids.

16

VIII. ALLERGEN EXTRACT STABILITY AND STORAGE

The stability and potency of allergen extracts can be

compromised by elevated temperatures, contamination

and protease degradation of key allergenic proteins

responsible for the efficacy of immunotherapy.

31-34,37

Several measures are taken by stock extract manufacturers

and healthcare personnel to minimize the risk of loss of

potency of extracts during normal storage and use.

Dilution of extracts alone can affect the long-term

potency of extracts. For example, diluted extracts have

lower concentrations of important preservatives and

stabilizers. Furthermore, lower concentrations of proteins

decrease three-dimensional protein structure stabilization

achieved through protein-interactions present at higher

protein concentrations. Finally, dilutions may also magnify

the effect of allergenic protein loss as a result of binding

to sites on glass vials that is essentially insignificant at

higher protein concentrations.

There are several “routine” operating procedures that

when performed consistently should promote extract

stability and reduce errors associated with the use of

outdated materials:

• Routinely check expiration dates on all products.

• Ensure that the stock inventory in refrigerators is

routinely rotated such that expiring products are

placed in the front and used first.

• Verify that the expiration dates on labels for

treatment and diagnostic sets are no later than the

stock extract used with the earliest expiration date.

• Discard or separate products that have expired.

• Ensure that personal allergen extract storage trays

are stored at recommended temperatures.

• Ensure that extracts are kept cool during extended

periods of mixing.

Manufacturer processing steps include additives that

stabilize the allergenic proteins and preservatives

that prevent contamination of the stock extract and

individual patient treatment sets derived from them.

Preservatives are added to allergen extract solutions

to prevent microbial growth in the event that bacteria

or fungi are introduced into the solution during the

preparation process or when needles are inserted

into vials for administration of immunotherapy. All

allergen extracts must contain preservatives that are

bacteriostatic. Bacteriostatic agents prevent the growth

of microbial contaminants like bacteria, but do not

necessarily kill microorganisms.

Sterilization and pasteurization processes that kill

microorganisms are less commonly used.

Phenol is a common bacteriostatic preservative added

to allergen extracts and is used at a final concentration

of approximately 0.4%. One possible ill effect of using

phenol is that it may denature (unfold or breakdown)

allergenic proteins even if in a 50% glycerin.

31,33

HSA

may protect against phenol’s adverse effects on

allergenic proteins.

31

Other recognized preservatives

such as thimerosal and methylparaben are not generally

used in allergen extract preparation.

Stabilizers are added to diluents to maintain the

structure of allergens in solution and prevent sticking or

adherence to the glass vials in which they are contained.

Common stabilizers include glycerin and HSA. Fifty

percent glycerin is often considered the best stabilizer

alternative and is also considered a preservative,

whereas HSA is not a preservative. Glycerin potently

stabilizes proteins in solution and inhibits proteases

found in some allergen extracts, and is bacteriostatic at

concentrations ≥20%.

37

Preservative and stabilizing properties decrease as the

concentration of glycerin is decreased. Glycerin, when

injected subcutaneously, can cause local irritation and

result is a burning sensation.

Allergen extracts are stored in refrigerators at a

temperature of 4ºC or in accordance with manufacturer

recommendations. A temperature range of 2˚- 8ºC is

considered acceptable by most experts. Given the

expense and temperature sensitivity of stock allergen

extract concentrates and mixed patient treatment

sets, it is also reasonable to conduct some form of

temperature monitoring to ensure that extracts are not

exposed to temperature extremes. For example, a log

of daily temperatures (See Refrigerator Temperature

Log Form) can be maintained or an automated

continuous temperature monitoring device can be

installed. Facilities might also consider installing

temperature alarms.

Many allergen extracts are heat sensitive. The loss in

potency when allergen extracts are exposed to high

temperatures (i.e., over 78ºF or 26ºC) may be due to the

heat-labile (-sensitive) proteins that unfold or degrade

at these temperatures. Loss of potency can also occur at

lower temperatures, including room temperature (i.e.,

68ºF – 72ºF and 22ºC). This is possibly due to proteases

in the extract that are activated at these temperatures

and degrade relevant allergen proteins in the extract.

Allergen extracts exposed to room temperature over

time may thus lose potency, such as extracts frequently

left out of the refrigerator for long periods during

testing or treatment. For example, skin testing trays

17

with extracts that are taken out of the refrigerator in

the morning every day and not replaced until the clinic

closes in the evening may suffer from reductions in

potency unless the trays are cooled while out of the

refrigerator. Short intervals for testing or treatment rarely

result in clinically significant losses of potency. Fifty

percent glycerin may help protect against the effects

of prolonged exposure to room temperature, possibly

due to its effect on proteolytic enzymes. Less is known

about the effects of freezing (<0ºC) on allergen extract

potency, but at least one study found a moderate loss of

potency when an extract was stored frozen and thawed

for use.

15

An increase in the number of multiple freeze-

thaw cycles increases the observed loss in potency

of extracts. Thus, extracts that are accidentally frozen

should be replaced with new extract prior to use.

Some extracts contain proteolytic enzymes or proteases

that can degrade proteins needed for allergen extract

effectiveness. Tree, grass and weed pollens and some

pet danders are particularly susceptible to these

proteases. For this reason, the most recent Practice

Parameters recommend the separation of extracts

with high proteolytic enzyme activities, such as mold

and cockroach, from other extracts, such as pollens.

Dust mite extracts do not appear to cause significant

degradation of pollen or animal dander extracts and

thus can be mixed together.

Investigations have shown that extracts stored in vials

only partially filled with solution are less stable. In

other words, 1 mL of extract in a 10-mL vial will lose

potency more rapidly than 10 mL of extract in a 10-

mL vial. This volume effect is more pronounced with

higher dilutions. For this reason, it is reasonable to

consider reordering and preparing treatment and

diagnostic materials as the extract volume in current

vials diminishes.

IX. SUMMARY

The preparation of allergen immunotherapy extracts is

a technical skill that requires training and a high level

of attention to detail. Errors may cause life-threatening

allergic reactions in patients receiving immunotherapy.

Using a team approach to develop clinic/facility-

specific policies and procedures and verify ongoing

competency will ultimately improve the quality and

precision of allergen immunotherapy preparation.

Ongoing review of these procedures will lead to

increased knowledge of and adherence by individuals

preparing allergen extracts. These steps will ensure

the end product is appropriately prepared according

to the most recent standards and manufacturer

recommendations. Thorough knowledge and training will

promote the safety of the patients entrusted to our care

and of those performing allergen extract preparation.

There are several major themes that new personnel

assigned to prepare allergen extracts should become

familiar with. These include, but are not limited to:

• Contamination is prevented by adequate training

and the use of using aseptic technique

• Accurate labels and color coding are highly

recommended to prevent errors

• Use of quality assurance checks throughout the

mixing process is highly recommended

• Initial treatment sets consist of a maintenance vial

and a series of 10-fold dilutions

• Stinging insect and aeroallergen extracts should

not be mixed

All personnel involved in allergen extract preparation

should be familiar with the contents of the most recent

Immunotherapy Practice Parameter and 2019 Updated

USP 797 Standards for allergen extract mixing. A

companion examination has been developed based on

this training document to assist in satisfying competency

assessment and documentation requirements. It is

currently available via the College Learning Connection.

18

XI. REFERENCES

1. Noon, L. (1911). Prophylactic inoculation against hay

fever. Lancet, 1, 1572-73.

2. Ross, R. N., Nelson, H.S., Finegold, I. (2000). Effec-

tiveness of specific immunotherapy in the treatment

of asthma: A meta-analysis of prospective, random-

ized, double-blind, placebo- controlled studies. Clin

Ther, 22, 329-41.

3. Ross, R. N., Nelson, H.S., Finegold, (2000). Effective-

ness of specific immunotherapy in the treatment of

allergic rhinitis: An analysis of randomized, prospec-

tive, single- or double-blind, placebo-controlled

studies. Clin Ther, 22, 342-350.

4. Ross, R. N., H.S., Finegold, I. (2000). Effectiveness of

specific immunotherapy in the treatment of hyme-

noptera venom hypersensitivity: A meta-analysis.

Clin Ther, 22, 351-8.

5. Calderon, M. A., Alves, B., Jacobson, M., Hurwitz,

B., Sheikh, A., Durham, S. (2007). Allergen injection

immunotherapy for seasonal allergic rhinitis. The Co-

chrane Database of Systematic Reviews, Jan 24(1).

CD001936.

6. Abramson, M. J., Puy, R. M., Weiner, J. M. (2003).

Allergen immunotherapy for asthma. The Cochrane

Database of Systematic Reviews. (4). $%001186.

7. Lockey, R., Bukantz, S., Bousquet, J. (Eds.) (2004).

Allergens and allergen immunotherapy. (3rd Ed).

8. Ewan, P. W., Alexander, M. M., Snape, C., Ind, P. W.,

Agrell, B., Drebord, S. (1988). Effective hyposensi-

tization in allergic rhinitis using a potent partially

purified extract of house dust mite. Clin Allergy, 18,

501-8.

9. Olsen, O. T., Larsen, K. R., Jacobsan, L., Svendsen, U.

G. (1997). A 1-year placebo-controlled, double-blind

house dust-mite immunotherapy study in asthmatic

adults. Allergy, 52, 853-859.

10. Haugaard, L., Dahl, R., Jacobsen, L. (1993). A con-

trolled dose-response study of immunotherapy with

standardized, partially purified extract of house dust

mite: Clinical efficacy and side effects. J Allergy Clin

Immunol, 91, 709-22.

11. Ohman, J. L., Jr., Sundin, B. (1987). Standardized

allergenic extracts derived from mammals. Clin Rev

Allergy, 5, 37-47.

12. Lombardero, M., Carreira, J., Duffort, O. (1988).

Monoclonal antibody based radioimmunoassay for

the quantitation of the main cat allergen (Fel d I or

Cat-1). J Immunol Methods, 108, 71-76.

13. American Academy of Allergy, Asthma and Immu-

nology (AAAAI) (1977). The use of standardized

allergen extracts. J Allergy Clin Immunol, 99, 583-6.

X. ACKNOWLEDGMENTS

ORIGINAL DOCUMENT CREATED IN 2007

Authored by:

Michael R. Nelson, MD, PhD, FAAAAI, FACAAI

Edited by:

Linda Cox, MD, FAAAAI

Tao T. Le, MD, MHS, FACAAI, FAAAAI

With Acknowledgments to:

Ms. Susan Kosisky, Ms. Anita Bienlein, Dr. Ceclia Mikita,

Mr. Eric Riddock, TSgt Adam Hughlett, TSgt Debra Horne

of the US Army Centralized Allergen Extract Laboratory at

Walter Reed Army Medical Center. Dr. Bryan Martin and

Dr. Renata Engler of the Walter Reed Vaccine Healthcare

Centers Network. Dr. Gary Gross and Dr. Don Aaronson,

MD of Advocacy Council of ACAAI; Dr. Linda Cox and

colleagues of the AAAAI Immunotherapy and Allergy

Diagnostics Committee and ACAAI Immunotherapy and

Diagnostics Committee and the members of ACAAI/

AAAAI Task Force on Practice Parameters.

DOCUMENT REVISED IN 2017

ACAAI Immunotherapy & Diagnostics Committee

John J. Oppenheimer, MD — Chair

Mike Tankersley, MD

Trever Burnett, MD

David B. Engler, MD

Warren V. Filley, MD

Desiree E. Larenas-Linnemann, MD

Alnoor A. Malick, MD

Anil Nanda, MD

Michael R. Nelson, MD, PhD

Ruby Pawankar MD, PhD, FRCP

Jorge A. Quel, MD

Noel Rodriguez, MD

Millard Tierce, IV, DO

Kevin M. White, MD

Ira Finegold, MD

Cheryl Bernstein, RN

19

14. Van Metre, T. E., Jr., Marsh, D. G., Adkinson, N. F.,

Jr., et al. (1989). Immunotherapy decreases skin

sensitivity to cat extract. J Allergy Clin Immunol, 83,

888-899.

15. Van Metre, T. T., Jr., Marsh, D. G., Adkinson, N. G., Jr.,

et al. (1988). Immunotherapy for cat asthma.

J Allergy Clin Immunol, 82, 1055-1068.

16. Ewbank, P. A., Murray, J., Sanders, K., Curran-Eberett,

D., Dreskin, S., Nelson, H. S. (2003). A double-blind,

placebo-controlled immunotherapy dose-response

study with standardized cat extract. J Allergy Clin

Immunol, 111, 155-161.

17. Dolz, I., Martinez-Cocera, C., Bartolome, J. M., Cimar-

ra, M. (1996). A double-blind, placebo-controlled

study of immunotherapy with grass-pollen extract

Alutard SQ During a 3-year period with initial rush

immunotherapy. Allergy, 51, 489-500.

18. Walker, S. M., Pajno, G. B., Lima, M. T., Wilson, D. R.,

Durham, S. R. (2001). Grass pollen immunotherapy

for seasonal rhinitis and asthma: A randomized,

controlled trial. J Allergy Clin Immunol, 107, 87-93.

19. Frew, A. J., Powell, R. J., Corrigan C. J., Durham, S. R.

(2006). Efficacy and safety of specific immunother-

apy with SQ allergen extract in treatment-resistant

seasonal allergic rhinoconjunctivitis. J Allergy Clin

Immunol, 117, 319-325.

20. Leynadier, F., Banoun, L., Dollois, B., et al. (2001). Im-

munotherapy with a calcium phosphate-adsorbed

five-grass pollen extract in Seasonal rhinoconjuncti-

vitis: A double-blind, placebo-controlled study. Clin

Exp Allergy, 31, 988-996.

21. Lockey, R., Slater, J., Esch, E. Preparation of standard-

ization of allergen extracts. In F. Adkinson, J. Yungin-

ger, W. Busse, B. Bochner, S. Holgate, & E. Simmons

(Eds.0. (2003). Middelton’s allergy principles and

practice (6th ed.). St. Louis: Mosby.

22. Creticos, P., Adkinson, N. F., Jr., Kagey-Sabotka, A.,

et al. (1985). Nasal challenge with ragweed pollen in

hay fever patients: Effect of immunotherapy. J Clin

Invest, 76, 2247-2253.

23. Creticos, P. S., Marsh, D. G., Proud, D., et al. (1989).

Responses to ragweed-pollen nasal challenge be-

fore and after immunotherapy.

J Allergy Clin Immunol, 84, 197-205.

24. Lent, A. M., Harbekc, R., Strand, M., et al. (2006). Im-

munologic response to administration of standard-

ized dog allergen extract at differing doses. J Allergy

Clin Immunol, 118, 1249-1256.

25. Durham, S. R., Walker, S. M., Varga, E. M., et al.

(1999). Long-term clinical efficacy of grass-pollen

immunotherapy. N Engl J Med, 341, 468- 475.

26. Cox, L., Nelson, H., Lockey, R., et al. (2011). Allergen

immunotherapy: A practice parameter third update.

J Allergy Clin Immunol, 127 (1 Suppl,) S1-S55. Erra-

tum. (2011). J Allergy Clin Immunol, 127, 840.

27. Oppenheimer, J. J., Nelson, H. S., Bock, S. A., Chris-

tensen, F., Leung, D. Y. (1992). Treatment of peanut

allergy with rush immunotherapy.

J Allergy Clin Immunol, 90, 256-262.

28. Nelson, H. S., Lahr, J., Rule, R., Bock, A., Leung, D.

(1997). Treatment of anaphylactic sensitivity to pea-

nuts by immunotherapy with injections of aqueous

peanut extract. J Allergy Clin Immunol, 99, 744-751.

29. Turkeltaub, P. Allergenic extracts. II. In vivo standard-

ization. In E. Middleton, JR., E. F. Ellis, N. F. Adkinson,

Jr., & J. W. Yunginger (Eds.). (1988). Allergy: Princi-

ples and practice (3rd ed.). St. Louis: Mosby.

30. USP Sterile Compounding Committee (2008, 2019).

USP <797> Guidebook to Pharmaceutical Com-

pounding — Sterile Preparations. U.S. Pharmacopeia

31. Vijay, H. M., Young, N. M., Bernstein, I. L. (1987).

Studies on Alternaria tenuis extracts under a variety

of storage conditions. Int Arch Allergy Appl Immu-

nol, 83, 325-328.

32. Grier, T. J., LeFevre, D. M., Duncan, E. A., Esch, R. E.

(2007). Stability of standardized grass, dust mite, cat,

and short ragweed allergens after mixing with mold

or cockroach extracts. Ann Allergy Asthma Immunol,

99, 151-160.

33. Niemeijer, N. R., Kauffman, H. F., van Hove, W., Du-

bois, A. E., de Monchy, J. G. (1996). Effect of dilution,

temperature, and preservatives on the long-term

stability of standardized inhalant allergen extracts.

Ann Allergy Asthma Immunol, 76, 535-540.

34. Weber, R. W. (2008). Guidelines for using pollen

cross-reactivity in formulating allergen immunother-

apy. J Allergy Clin Immunol, 122, 219-221.

35. Hunt, K. J., Valentine, M. D., Sobotka, A. K., et al.

(1978, July 27). A controlled trial of immunotherapy

in insect hypersensitivity. N Engl J Med, 299(4), 157-

161.

36. Golden, B. K., Moffitt, J., Nicklas, R. A., et al. (2011).

Stinging insect hypersensitivity: A practice parame-

ter update 2011. J Allergy Clin Immunol, 127, 852-

854.

37. Soldatova, L. N., Paupore, E. J., Burk, S. H., Pastor,

R. W., Slater, J. E. (2000). The stability of house dust

mite allergens in glycerinated extracts. J Allergy Clin

Immunol, 105, 482-488.

38. Grier, TJ. How’s my dosing? A one-step, math-free

guide for comparing your clinic’s maintenance

immunotherapy doses to current practice parameter

recommendations. Ann Allergy Asthma Immunol

108 (2012) 201-205

20

XII. APPENDICES

Appendix 1. Effective Dose Range for Allergen Extracts, US Standardized Units

Table IX. Probable effective dose range for standardized and non-standardized US-licensed allergen extracts

Allergenic extract

Labeled potency

or concentration

Probable effective

dose range

Range of estimated major allergen

content in US-licensed extracts

Dust mites: D farinae and

D pteronyssinus

3,000, 5,000, 10,000, and

30,000 AU/mL

500-2,000 AU 10,000 AU/mL

20-160 µg/Ml Der p 1, Der f 1*

2-180 µg/mL Der p 2, Der f 2*

78-206 µg./mL Der p 1, Der f 1†

13-147 µg/mL Der p 2, Der f 2†

Cat hair 5,000 and 10,000

BAU/mL

1,000-4,000 BAU 10,000 AU/mL

20-50 µg/mL Fel d 1*‡

30-100 µg/mL cat albumin§

Cat pelt 5,000-10,000 BAU/mL 1,000-4,000 BAU 10,000 BAU/mL

20-50 µg/mL Fel d 1 *‡

400-2,000 µg/mL cat albumin§

Grass, standardized 100,000 BAU/mL 1,000-4,000 BAU 100,000 BAU/mL

425-1,100 µg/mL Phl p 5*

506-2,346 µg/mL group 1||

Bermuda 10,000 BAU/mL 300-1,500 BAU 10,000 BAU/mL

141-422 Cyn d 1 µg/mL*

Short ragweed 1:10, 1:20 wt/vol,

100,000 AU/mL

6-12 µg of Amb a 1 or 1,000-

4,000 AU

1:10 wt/vol

300 µg/mL Amb a 1‡

Concentration of Amb a 1 is

on the label of wt/vol extracts

Nonstandardized

AP Dog

1:100 wt/vol 15 µg of Can f 1 80-400 µg/mL Can f 1†

10-20 µg/mL dog albumin¶

Nonstandardized extract,

dog

1:10 and 1:20 wt/vol 15 µg of Can f 1 0.5 to 10 µg/mL Can f 1†

<12-1,500 µg/mL dog albumin¶

Nonstandardized

extracts: pollen

1:10 to 1:40 wt/vol or

10,000-40,000 PNU/mL

0.5 mL of 1:100 or 1:200 wt/vol NA

Nonstandardized

extracts: mold/fungi,

cockroach

1:10 to 1:40 wt/vol or

10,000-40,000 PNU/mL

Highest tolerated dose NA

Hymenoptera venom 100 µg/mL single venom

300 µg/mL in mixed

vespid extract

50-200 µg of each venom 100-300 µg/mL of venom protein

Imported fire ant 1:10 to 1:20 wt/vol