Adams 2021.0.2

Getting Started: Adams Car

Worldwide Web

www.mscsoftware.com

Support

http://www.mscsoftware.com/Contents/Services/Technical-Support/Contact-Technical-Support.aspx

Disclaimer

This documentation, as well as the software described in it, is furnished under license and may be used only in accordance with the

terms of such license.

MSC Software Corporation reserves the right to make changes in specifications and other information contained in this document

without prior notice.

The concepts, methods, and examples presented in this text are for illustrative and educational purposes only, and are not intended

to be exhaustive or to apply to any particular engineering problem or design. MSC Software Corporation assumes no liability or

responsibility to any person or company for direct or indirect damages resulting from the use of any information contained herein.

User Documentation: Copyright © 2021 MSC Software Corporation. Printed in U.S.A. All Rights Reserved.

This notice shall be marked on any reproduction of this documentation, in whole or in part. Any reproduction or distribution of this

document, in whole or in part, without the prior written consent of MSC Software Corporation is prohibited.

This software may contain certain third-party software that is protected by copyright and licensed from MSC Software suppliers.

Additional terms and conditions and/or notices may apply for certain third party software. Such additional third party software terms

and conditions and/or notices may be set forth in documentation and/or at

http://www.mscsoftware.com/thirdpartysoftware (or successor

website designated by MSC from time to time). Portions of this software are owned by Siemens Product Lifecycle Management, Inc.

© Copyright 2021

The MSC Software logo, MSC, MSC Adams, MD Adams, and Adams are trademarks or registered trademarks of MSC Software

Corporation in the United States and/or other countries. Hexagon and the Hexagon logo are trademarks or registered trademarks of

Hexagon AB and/or its subsidiaries. FLEXlm and FlexNet Publisher are trademarks or registered trademarks of Flexera Software.

Parasolid is a registered trademark of Siemens Product Lifecycle Management, Inc. All other trademarks are the property of their

respective owners.

ADAM:V2021.0.2:Z:Z:Z:DC-GS-CAR

Corporate Europe, Middle East, Africa

MSC Software Corporation MSC Software GmbH

4675 MacArthur Court, Suite 900 Am Moosfeld 13

Newport Beach, CA 92660 81829 Munich, Germany

Telephone: (714) 540-8900 Telephone: (49) 89 431 98 70

Toll Free Number: 1 855 672 7638 Email: [email protected]

Email: ameri[email protected]

Japan Asia-Pacific

MSC Software Japan Ltd. MSC Software (S) Pte. Ltd.

KANDA SQUARE 16F 100 Beach Road

2-2-1 Kanda Nishikicho, Chiyoda-ku #16-05 Shaw Tower

Tokyo 101-0054, Japan Singapore 189702

Telephone: (81)(3) 6275 0870 Telephone: 65-6272-0082

Email: MSCJ.Marke[email protected] Email: [email protected]

Documentation Feedback

At MSC Software, we strive to produce the highest quality documentation and welcome your feedback.

If you have comments or suggestions about our documentation, write to us at:

documentation-

.

Please include the following information with your feedback:

Document name

Release/Version number

Chapter/Section name

Topic title (for Online Help)

Brief description of the content (for example, incomplete/incorrect information, grammatical

errors, information that requires clarification or more details and so on).

Your suggestions for correcting/improving documentation

You may also provide your feedback about MSC Software documentation by taking a short 5-minute

survey at:

http://msc-documentation.questionpro.com.

Note: The above mentioned e-mail address is only for providing documentation specific

feedback. If you have any technical problems, issues, or queries, please contact

Technical

Support

.

Getting Started Using Adams Car

Getting Started Using Adams Car

Overview

14

Introducing Adams Car

Overview

This chapter introduces you to Adams Car. It contains the following sections:

Starting Adams Car Standard Interface

Starting Adams Car Template Builder

Switching Between Interface Modes

Familiarizing Yourself with Adams Car

Plotting Results

Starting Adams Car Standard Interface

In this section, you learn how to start Adams Car Standard Interface in the Windows and the Linux

environments.

In the Windows environment, you start Adams Car from the Start button. In the Linux environment, you

start Adams Car from the Adams Toolbar. For more information, see the online help for Running and

Configuring Adams.

To start Adams Car on Windows:

1. From the Start menu, point to Programs, point to Adams x (where x is release number), and then

select Adams Car.

The Welcome dialog box appears on top of the Adams Car main window.

2. Do one of the following:

• If the Welcome dialog box contains the options Standard Interface and Template Builder, select

Standard Interface, and then select OK.

• If the Welcome dialog box does not contain any options, then Adams Car is already configured

to run in standard mode. Select OK.

The Adams Car Standard Interface window appears as shown below. Familiarize yourself with the

Adams Car window and read the tips in Familiarizing Yourself with Adams Car.

15

Introducing Adams Car

Starting Adams Car Standard Interface

Figure 1 Adams Car Standard Interface

To start Adams Car on Linux:

1. At the command prompt, enter the command to start the Adams Toolbar, and then press Enter. The

standard command that MSC Software provides is

adamsx, where x is the version number, for

example 2021_0_2

The Adams Toolbar appears.

Getting Started Using Adams Car

Starting Adams Car Template Builder

16

2. Click the Adams Car icon

The Welcome dialog box appears on top of the Adams Car main window.

3. Do one of the following:

• If the Welcome dialog box contains the options Standard Interface and Template Builder, select

Standard Interface, and then select OK.

• If the Welcome dialog box does not contain any options, then Adams Car is already configured

to run in standard mode. Select OK.

The Adams Car Standard Interface window appears as shown above. Familiarize yourself with the

Adams Car window and read the tips in Familiarizing Yourself with Adams Car.

Starting Adams Car Template Builder

Before you start Adams Car Template Builder, make sure that your private configuration file, .acar.cfg,

shows that you can work in expert-user mode. Your private configuration file is located in your home

directory.

To check the user mode:

1. In a text editor, such as jot or notepad, open .acar.cfg.

2. Verify that the following line appears as shown:

ENVIRONMENT MDI_ACAR_USERMODE expert

This line sets the user mode for the Adams Car session.

To start Adams Car Template Builder on Windows:

1. From the Start menu, point to Programs, point to Adams x (where x is the release number), and then

select Adams Car.

The Welcome dialog box appears on top of the Adams Car main window.

2. Select Template Builder.

3. Select OK.

The Adams Car Template Builder window appears as shown in the figure below. Familiarize yourself

with the Adams Car window and read the tips in Familiarizing Yourself with Adams Car.

17

Introducing Adams Car

Starting Adams Car Template Builder

Figure 2 Adams Car Template Builder

Getting Started Using Adams Car

Switching Between Interface Modes

18

To start Adams Car Template Builder on Linux:

1. At the command prompt, enter the command to start the Adams Toolbar, and then press Enter. The

standard command that MSC Software provides is

adamsx, where x is the version number, for

example

adams2021_0_2.

The Adams Toolbar appears.

2. Click the Adams Car icon .

The Welcome dialog box appears on top of the Adams Car main window.

3. Select Template Builder.

4. Select OK.

The Adams Car Template Builder window appears as shown in the figure above. Familiarize yourself

with the Adams Car window and read the tips in Familiarizing Yourself with Adams Car.

Switching Between Interface Modes

Once you have started Adams Car in the Standard Interface or Template Builder modes, you can easily switch

between them.

To switch between modes:

In Standard Interface: From the Tools menu, select Adams Car Template Builder.

In Template Builder: From the Tools menu, select Adams Car Standard Interface.

Familiarizing Yourself with Adams Car

Take a few minutes to familiarize yourself with the Adams Car main window.

The following tips help you quickly become familiar with Adams Car:

You use the menus along the top of the window to execute commands and display dialog boxes.

Notice that some menus are shaded in grey. This indicates that you cannot execute these commands

because you do not have a subsystem open. When you open a subsystem, these menus change to

black indicating that you can execute the commands.

You can use the main shortcut menu to execute simple commands, such as rotating views, zooming,

and fitting assemblies in the main window. To display the main shortcut menu, right-click in the

main window, away from any entities.

Instead of manually entering text in boxes that require database objects, you can have Adams Car

automatically do this task for you. To do this, right-click the text box of interest, and then select an

option. For example, if you were modifying a hardpoint, Adams Car would present you with the

following options:

• Point to Hardpoint (or the entity of interest) and then select Pick. On the main window, place

the cursor on top of the hardpoint. When the name of the hardpoint appears, you can click the

left mouse button to select that hardpoint.

19

Introducing Adams Car

Plotting Results

• Point to Hardpoint, and then select Guesses. From the pop-up menu that appears, select the

entity name you want to use.

• Point to Hardpoint, and then select Browse. Adams Car displays the Database Navigator, which

contains a list of entities, hardpoints in this case. Double-click the entity name you want to use.

Plotting Results

When you’re ready to review the results of your analyses, you can display the post-processing tool and view

the results of the simulations you performed.

To plot results:

1. While in Adams Car Standard Interface, from the Review menu, select Postprocessing Window or

press F8.

Adams Car launches Adams PostProcessor, a post-processing tool that lets you view the results of

simulations you performed. For more information about Adams PostProcessor, see the Adams

PostProcessor online help.

2. To return to Adams Car, select the Return to Modeling Environment tool or press F8.

Getting Started Using Adams Car

Plotting Results

20

13

Introducing the Driving Machine

Overview

Introducing the Driving Machine

Overview

This tutorial introduces you to the Driving Machine and the associated Event Builder. It contains the

following sections:

About the Driving Machine

About the Event Builder

About the Driving Machine

You can use Adams Car to study full-vehicle behavior for many different aspects of vehicle development, such

as handling, ride, and durability.

Adams Car offer several standard full-vehicle analyses (ramp steer, straight line braking, and so on) allowing

engineers and analysts to quickly characterize certain vehicle attributes. In addition to standard full-vehicle

analyses, the Driving Machine supports an XML event file that lets you create your own custom full-vehicle

analyses. These analyses are typically built from a number of mini-maneuvers, which when simulated in

succession, define a meaningful vehicle test. An example of such a test could be a braking-in-turn analysis,

which would consist of the following mini-maneuvers:

1. Drive along a road in a straight line, maintaining a constant velocity. When a constant velocity has

been achieved for a specified amount of time and within a prescribed tolerance, end the first mini-

maneuver.

2. Start the second mini-maneuver by steering the vehicle onto a prescribed radius and maintaining the

same velocity. When the velocity has stabilized for a set amount of time and within a prescribed

tolerance, end the second mini-maneuver.

3. Start the third mini-maneuver by maintaining the previous radius and velocity from the second mini-

maneuver. After a two-second delay, apply the brake to achieve a desired longitudinal deceleration

while maintaining the radius from the second mini-maneuver by controlling the steering wheel.

For a human driver, this is quite a simple task: you simply drive in a straight line, turn the steering wheel, and

then apply the brake. In the Adams Car environment, you have more control over the driving event. Such an

analysis requires a reasonably complex event file.

Looking at the mini-maneuvers described above, the control attributes for each mini-maneuver are.

Steering wheel has to keep the vehicle straight. Throttle has to maintain vehicle speed. Gear, clutch,

and brake are not used.

Steering wheel has to steer the vehicle, then control the radius of turn. Throttle has to maintain

vehicle speed. Gear, clutch, and brake are not used.

Steering wheel has to maintain the radius of turn (steering motion will change during braking based

on the understeer/oversteer characteristics of the vehicle). Brake has to be applied and controlled to

achieve the desired lateral acceleration. Throttle has to be lifted. Application of the clutch will need

to be considered also.

Getting Started Using Adams Car

About the Event Builder

14

The Driving Machine permits a fine level of control over the full-vehicle model. This control has historically

been exercised by using a .

dcf file, which is based on the TeimOrbit data file standard. The Driving Machine

now uses XML event files to describe mini-maneuvers. You can still access .

dcf files, however, Driving

Machine automatically converts them to XML event file format.

About the Event Builder

The Event Builder lets you create and modify XML event files. The information in a new full-vehicle analysis

is then saved in an .

xml-based file, which can be used in the driving control file full-vehicle analysis.

The Event Builder consists of two distinct interfaces:

The mini-maneuver creation interface - Used to quickly create the mini-maneuvers; there is no limit

to the number of mini-maneuvers that can be created.

The mini-maneuver editor - Used to specify the Driving Machine parameters for each separate mini-

maneuver. In the example maneuver specified earlier, you would first create three mini-maneuvers,

then fill in the details for each mini-maneuver (steering, throttle, clutch, gear, brake, and end

conditions). In this tutorial, you will go through this process.

13

Using the Event Builder

Overview

Using the Event Builder

Overview

In this chapter, you will learn the basics of creating multiple mini-maneuvers, establishing the appropriate

application areas for those mini-maneuvers, and setting end conditions for each mini-maneuver.

The chapter contains the following sections:

Creating an Event

Creating the Three Mini-Maneuvers

Defining the Mini-Maneuver Parameters

Running the New Analysis

Creating an Event

Before you can create an event, you must create a new file, as explained next.

To display the Event Builder:

1. Open the assembly MDI_Demo_Vehicle.asy.

2. From the Simulate menu, point to Full-Vehicle Analysis, and then select Event Builder.

Adams Car displays the Event Builder, which is grayed out because you do not have a .

xml file yet.

To create a new file:

1. From the Event Builder’s File menu, select New.

The New File dialog box appears.

2. Enter the name of the event: braking_in_a_turn. This is the name of the file that will be saved to your

hard drive or network drive with a .

xml extension.

3. Select OK.

Your Adams product creates the file and also defines the first mini-maneuver,

MINI_1.

Entering Set-up and Global Parameters

The top of the Event Builder window, as shown next, has three fields and two tabs that provide global

parameters and set initial conditions.

Getting Started Using Adams Car

Creating the Three Mini-Maneuvers

14

The Event File text box shows the file name you specified when you created or opened the file, and the

path, for new files, is the working directory. You can’t change the file name or path in the Event Builder. You

can use the Speed and

Gear text boxes to enter an initial speed and gear, respectively, for the vehicle prior to

starting the first mini-maneuver.

The

Static Set-up tab lets you complete the definition of the vehicle state prior to beginning of the first

mini-maneuver. The

Gear Shifting Parameters tab lets you define global parameters related to gear

shifting. The Event Builder outputs this information so that the Driving Machine uses these parameters for

any shifting required by any mini-maneuver.

For this exercise, the default Gear Shifting Parameters should be adequate, so you won’t change them. Because

the first mini-maneuver that you specify is going to be a straight line, you will use the straight static setup.

For a description of the static setup methods available in the Driving Machine, see

Structure of Event Files in the

Adams Car online help.

1. In the

Static Set-up tab, change set Task to straight. Note that the rest of the parameters are not

used because they will be overwritten by the initial values computed during the quasi-static setup.

You must set the initial velocity of the vehicle. The value of the initial velocity depends on the units

in which you are using the Event Builder.

2. To check the units or make a change, from the Settings menu, select Units.

By default, the length unit is set to meters and the time unit is set to seconds. Therefore, the velocity

must be set in meters/second.

3. To verify that velocity units are in meters/second, click in the Speed text box at the top of the Event

Builder, and then read what is displayed in the Current Field Unit text box at the bottom of the Event

Builder.

4. To set the target vehicle velocity, in the Speed text box, enter 27.7 (as previously explained, units are

meters/second), which corresponds to approximately 100 km/h.

5. To set the initial gear, in the Gear text box, enter 5.

Creating the Three Mini-Maneuvers

To complete the braking-in-turn event, you must create three mini-maneuvers.

15

Using the Event Builder

Defining the Mini-Maneuver Parameters

To create the mini-maneuvers:

1. To go to the mini-maneuver table editor, select .

The mini-maneuver table editor appears. Note that by default, the first mini-maneuver,

MINI_1, is

already defined.

2. To create one more mini-maneuver, in the Name text box at the bottom of the Event Builder

window, enter MINI_2, and then select Add.

3. To create the last mini-maneuver, in the Name text box, enter MINI_3, and then select Add.

The mini-maneuver window appears as follows:

4. In the Abort Time for MINI_2, change the abort time to 5.

5. To save the event file with the 3 mini-maneuvers, select Save.

Your Adams product saves the file,

braking_in_a_turn.xml, in your current working directory.

Defining the Mini-Maneuver Parameters

Now that you defined the three mini-maneuvers, you must define what each of the application areas and end

conditions will do during the mini-maneuvers.

The application areas are steering, throttle, brake, clutch, and gear. For each application area, you define the

Driving Machine control method (open, machine, or SmartDriver).

End conditions define a vehicle state that the Driving Machine uses to terminate a mini-maneuver. End

conditions are extremely flexible, and let you define many types of situations that cause the vehicle state to

move on to the next mini-maneuver. The following are some example end conditions:

End conditions can have a single condition, such as time is greater than 5 seconds.

End conditions can have a single value that must be within a tolerance over a prescribed period of

time. Lateral acceleration is 0.5 g over a two-second period and within a 0.05 g tolerance.

Multiple end conditions, such as time is greater than 5 seconds or vehicle velocity is lower than

10 kph.

Combined end condition, such as vehicle velocity equal 100 kph (within a tolerance) and

longitudinal acceleration equals 0 g (within a tolerance). Event Builder lets you group end

conditions, allowing you to specify multiple conditions required to terminate a maneuver.

For more information on end conditions, see

Specifying Conditions in the Adams Car online help.

Getting Started Using Adams Car

Defining the Mini-Maneuver Parameters

16

To define mini-maneuver parameters for MINI_1:

1. To access the mini-maneuver property editor, double-click the name of the mini-maneuver you want

to edit. In this case, MINI_1.

2. For the first mini-maneuver, the vehicle should drive in a straight line and maintain constant velocity.

To achieve this, set the following parameters:

• Steering tab

Actuator Type: rotation

Control Method: machine

Steer Control: straight

The Steer Control setting enables the Driving Machine to drive the vehicle in a straight line.

• Throttle tab

Control Method: machine

Speed Control: maintain

Velocity: 27.7

The Velocity setting enables the Driving Machine to maintain the steady-state velocity that you

established earlier. The Driving Machine will control the throttle to maintain this velocity much

like a cruise control system.

• Braking tab

Control Method: machine

The Throttle and Brake settings control the longitudinal velocity of the vehicle.

• Gear tab

Control Method: open

Control Type: constant

Control Value: 5

Maintain the same gear specified for the static setup.

• Clutch tab

Control Method: open

Control Type: constant

Control Value: 0.0

For the first mini-maneuver, you’re using the Driving Machine for the steering and the throttle,

so you can maintain the vehicle speed during straight-line driving.

The purpose of the first mini-maneuver is to reach a dynamic steady-state end condition.

Although not absolutely necessary for this type of event, it helps demonstrate some important

aspects of the Driving Machine. To satisfy a steady-state condition, the vehicle must be traveling

a straight line (very low lateral acceleration) at a stable velocity (very low longitudinal velocity).

You can use end conditions to group these two conditions together to satisfy the steady-state

requirements.

17

Using the Event Builder

Defining the Mini-Maneuver Parameters

To create end conditions for MINI_1:

1. Select the Conditions tab.

2. Select .

3. In the Name text box, enter END_2.

4. Select Add.

5. Modify the end conditions as follows:

• END_1

Type: lon_accel

Test : ==

Trigger Value: 0.0

Error: 0.05

Filter Time: 2.0

Delay Time:0.0

Group Name: MINI_1

• END_2

Type: lat_accel

Test : ==

Trigger Value: 0.0

Error: 0.05

Filter Time: 2.0

Delay Time: 0.0

Group Name: MINI_1

Note that you used

MINI_1 for both group names. Because END_1 and END_2 have the same

Group Name, the vehicle state must satisfy both end conditions for the maneuver switch to occur.

6. Select Save.

To define mini-maneuver parameters for MINI_2:

1. Select to the left of Name label for the text box containing MINI_1.

2. Double-click on the name of the mini-maneuver, MINI_2.

3. Set the mini-maneuver parameters as follows:

• Steering tab

Actuator: rotation

Control Method: machine

Getting Started Using Adams Car

Defining the Mini-Maneuver Parameters

18

Steer Control: skidpad

Entry Distance: 20.0

Radius: 120

Turn Direction: Right

These parameters will start the vehicle turning at the beginning of the second mini-maneuver.

• Throttle tab

Control Method: machine

Speed Control: maintain

Velocity: 27.7

These parameters allow the Driving Machine to maintain the straight line velocity established in

MINI_1. The steering parameters established in the steering block are not modified.

• Braking tab

Control Method: machine

• Gear tab

Control Method: open

Control Type: constant

Control Value: 5

Maintain the same gear specified for the static setup.

• Clutch tab

Control Method: open

Control Type: constant

Control Value: 0.0

For the second mini-maneuver, you’re tellling the Driving Machine to make a right turn and

control the vehicle on a radius of 120 m.

Next, you will create two end conditions to verify that the vehicle has reached a steady-state

cornering condition.

To create end conditions for MINI_2:

1. Select the Conditions tab.

2. In the Name text box, enter END_1.

3. Select Add.

4. Create the second end condition, END_2, just as you created the first.

5. Modify the end conditions as follows:

• END_1

Condition Type: lon_accel

19

Using the Event Builder

Defining the Mini-Maneuver Parameters

Test Type: ==

Trigger Value: 0.0

Error: 0.05

Filter Time: 2.0

Delay Time: 0.0

Group Name: MINI_2

• END_2

Condition Type: curvature

Test Type: ==

Trigger Value: 0.00833

Error: 0.00005

Filter Time: 2.0

Delay Time: 0.0

Group Name: MINI_2

These end conditions ensure that a radius of approximately 120 m is followed at a velocity of 100

kph.

6. Select Save.

To define mini-maneuver parameters for MINI_3:

1. Select .

2. Double-click on the name of the mini-maneuver, MINI_3.

3. Set the mini-maneuver parameters as follows:

• Steering tab

Actuator: rotation

Control Method: machine

Steer Control: skidpad

Entry Distance: 0.0

Radius: 120

Turn Direction: Right

These parameters maintain the radius from the previous mini-maneuver.

• Throttle tab

Control Method:machine

• Braking tab

Control Method: machine

Getting Started Using Adams Car

Defining the Mini-Maneuver Parameters

20

Speed Control: lon_accel

Start Time: 1.0

Long. Acc.: - 3.0

These parameters drop the throttle at the beginning of the third mini-maneuver to zero, and

control the deceleration to 3.0 m/s

2.

• Gear tab

Control Method: machine

The Driving Machine controls the gear selection.

• Clutch tab

Control Method: machine

The Driving Machine controls the clutch selection.

For the third mini-maneuver, you use the Driving Machine for all vehicle activity; you want the

Driving Machine to maintain the vehicle radius while at the same time braking the vehicle at 3

m/s

2

. You use a single end condition for the third mini-maneuver, which is velocity. You trigger

the end of the simulation if the velocity is below 10 kph which is approximately 2.77 m/s.

To create the end condition for MINI_3:

1. Select the Conditions tab.

2. In the Name text box, enter END_1.

3. Select Add.

4. Modify the end condition as follows:

• END_1

Condition Type: velocity

Test Type: <<

Trigger Value: 2.77

Error:0.01

Filter Time: 0.0

Delay Time: 0.0

5. Select Save. You can then select Cancel to close the Event Builder window.

By default, your Adams product saves the file in the current working directory. If you are not sure

where the current working directory is located, do following:

• In Adams Car, from the File menu, select Select Directory.

This displays a dialog that shows the current working directory.

21

Using the Event Builder

Running the New Analysis

Running the New Analysis

To run the new analysis:

1. Do one of the following, depending on your Adams product.

In Adams Car:

• From the Simulate menu, point to Full-Vehicle Analysis, and then select File Driven Events.

• Double-click the Driver Control Files text box to display a file selection dialog box that already

points to your working directory. Then, double-click the name of the new event file you created

in this tutorial (braking_in_a_turn.xml).

• In the Output Prefix text box, enter Event_Build.

• Leave the other parameters set to their defaults. For help on filling out this dialog box, press F1.

• Select OK to run the analysis.

You are now ready to use the Event Builder to run full-vehicle analyses.

Getting Started Using Adams Car

Running the New Analysis

22

31

Suspension Analysis Tutorial

What You Will Create and Analyze

Suspension Analysis Tutorial

This tutorial teaches you how to modify and analyze a double-wishbone suspension.

This chapter includes the following sections:

What You Will Create and Analyze

Setting Up the Suspension and Steering Subsystems

Performing a Baseline Parallel Wheel Travel Analysis

Performing a Baseline Pull Analysis

Modifying the Suspension and Steering Subsystem

Performing an Analysis on the Modified Assembly

Comparing the Analysis Results

Finishing Up

This tutorial takes about one hour to complete.

What You Will Create and Analyze

During this tutorial, you analyze and modify an assembly of a front suspension and steering subsystem. To

perform the analysis, you must first create a double-wishbone suspension and steering subsystem from

standard Adams Car templates and subsystems. Adams Car templates define a subsystem’s topology and

specify how one subsystem connects to another. Templates also contain default parameters, such as locations,

part masses, and inertias.

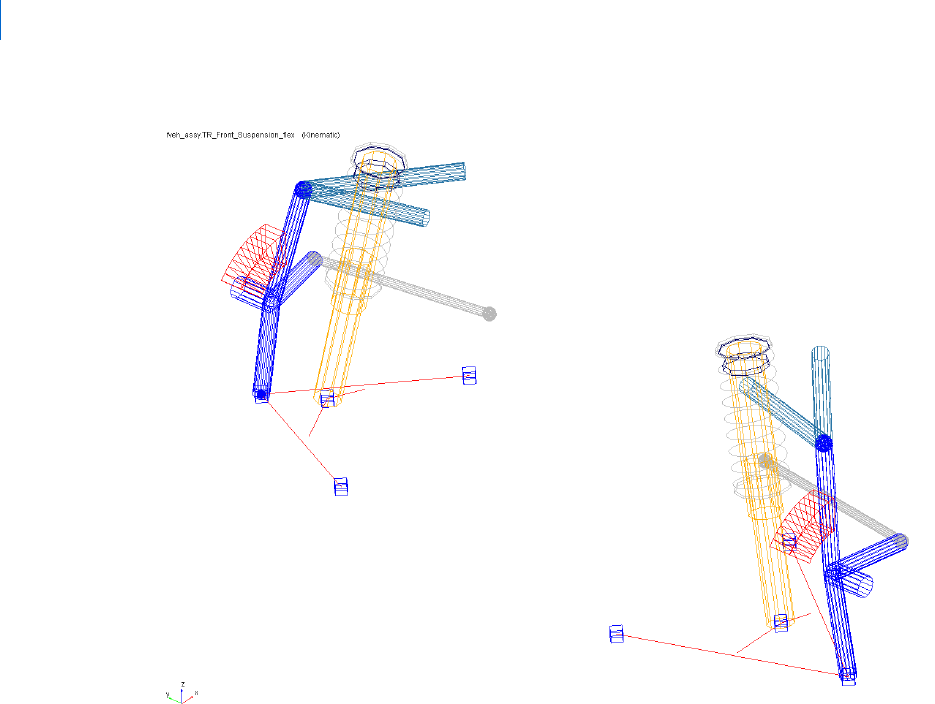

The figure shows the suspension and steering assembly (in shaded mode) that you will analyze and modify.

Getting Started Using Adams Car

Setting Up the Suspension and Steering Subsystems

32

Figure 1 Suspension and Steering Assembly

After you create the suspension and steering assembly, you perform two types of analyses to understand its

kinematics:

A baseline parallel wheel travel analysis that moves the assembly vertically through the suspension’s

rebound-bump travel.

A baseline pull analysis to measure the brake pull at the steering wheel.

Once you understand the kinematics of the assembly, you modify the suspension subsystem’s geometry to

decrease the scrub radius, which should reduce the pull on the steering wheel. You confirm the reduction by

analyzing the modified assembly again, using the same type of analysis and comparing the new results to the

results yielded by the previous analysis.

Setting Up the Suspension and Steering Subsystems

In this section, you work with a suspension and steering assembly from two subsystems: a suspension

subsystem and a steering subsystem. You create the suspension subsystem using the standard double-

wishbone template. You don’t need to create the steering subsystem. Instead, you can open an existing

subsystem that we’ve provided.

After creating and opening the subsystems, you create an assembly that contains the subsystems and a test rig.

33

Suspension Analysis Tutorial

Setting Up the Suspension and Steering Subsystems

Creating a New Front Suspension Subsystem

You create the front suspension subsystem based on a double-wishbone design stored in the standard template

named

_double_wishbone.tpl, and then save it.

After you create the subsystem, you save it in an Adams Car database. When you save a subsystem, Adams

Car stores it in the database designated as the default writable database. Initially, the private database is the

default writable database, but as you become more familiar with Adams Car, you can change your writable

database. Later, when you are sure the design is complete or ready for review, you can have your database

administrator save the file in a shared database or allow others to access it from your private database.

To create the front suspension subsystem:

1. Start Adams Car Standard Interface as described in Starting Adams Car Standard Interface.

2. From the File menu, point to New, and then select Subsystem.

The New Subsystem dialog box appears.

3. In the Subsystem Name text box, enter UAN_FRT_SUSP.

4. Set Minor Role to front. A minor role defines the subsystem’s function and its placement in the

assembly (for example, front or rear). In this case, you select front because you are creating a front

suspension.

5. Right-click the Template Name text box, point to Search, and then select shared_car_database.

The Select File dialog box appears.

6. Select templates.tbl and double-click _double_wishbone.tpl.

The Template Name text box now contains the file

_double_wishbone.tpl and an alias to its

directory path.

7. Verify that Translate from default position is not selected.

8. Select the Comment tool .

The Entity Comment dialog box appears.

9. In the Comment Text text box, enter Baseline UAN Front Suspension.

10. Select OK.

11. Select OK again.

Adams Car creates the suspension subsystem using the default data contained in the template and

displays it as shown next:

Tip: For information on any dialog box, press F1 when the dialog box is active.

Getting Started Using Adams Car

Setting Up the Suspension and Steering Subsystems

34

Figure 2 Suspension Subsystem

To save the suspension subsystem:

From the File menu, select Save.

Adams Car saves the subsystem in your default writable database, which might be your private

database. For more information on databases, see the Adams Car online help.

Creating a Suspension Assembly

In this section, you create a new suspension assembly and add to it a steering subsystem.

To create the suspension assembly:

1. From the File menu, point to New, and then select Suspension Assembly.

The New Suspension Assembly dialog box appears.

35

Suspension Analysis Tutorial

Performing a Baseline Parallel Wheel Travel Analysis

2. In the Assembly Name text box, enter my_assembly.

3. Click the folder icon next to Suspension Subsystem.

The name of the suspension subsystem you just created appears.

4. Select Steering Subsystem.

5. Right-click the Steering Subsystem text box, point to Search, and then select the

shared_car_database.

The Select File dialog box appears.

6. Select subsystems.tbl and double-click MDI_FRONT_STEERING.sub.

The Steering Subsystem text box now contains

MDI_FRONT_STEERING.sub and an alias to its

directory path.

Note that by default Adams Car selects a test rig for the assembly,

__MDI_SUSPENSION_TESTRIG.

7. Select OK.

The Message Window appears, informing you of the steps Adams Car takes when creating the

assembly.

Adams Car displays the suspension and steering assembly in the main window.

8. Select Close, to close the Message Window.

Performing a Baseline Parallel Wheel Travel Analysis

You now perform a parallel wheel travel analysis on the suspension and steering assembly, and then plot and

view the results, as explained in the following sections:

Defining Vehicle Parameters

Performing the Analysis

Animating the Results

Plotting the Results

Defining Vehicle Parameters

Before performing a suspension analysis, you must specify several parameters about the vehicle in which you

intend to use the suspension and steering subsystems. These parameters include the vehicle’s wheel base and

sprung mass, whether or not the suspension is front- or rear-wheel drive, and the braking ratio. For this

analysis, you enter the parameters to indicate front-wheel drive and a brake ratio of 64% front and 36% rear.

To define vehicle parameters:

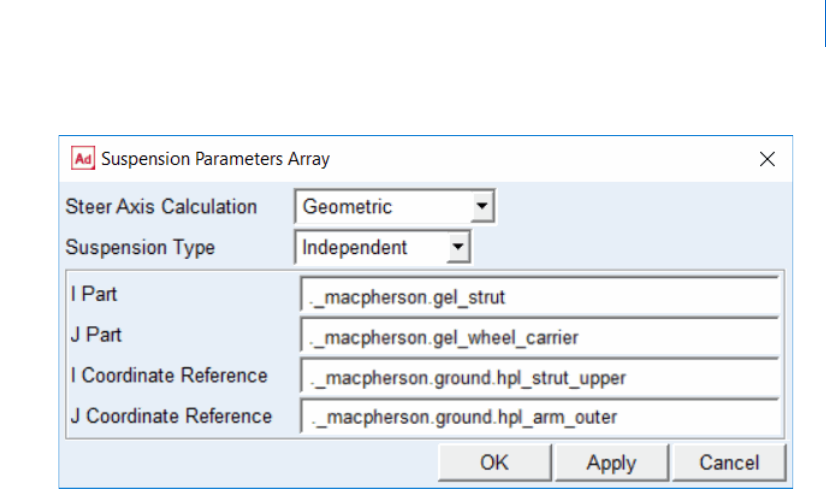

1. From the Simulate menu, point to Suspension Analysis, and then select Set Suspension Parameters.

The Suspension Analysis: Setup Parameters dialog box appears. It contains default settings to help you

quickly set up a suspension analysis.

2. Set up the analysis as follows:

• Suspension Assembly: my_assembly

Getting Started Using Adams Car

Performing a Baseline Parallel Wheel Travel Analysis

36

• Tire Model: User Defined

• Tire Unloaded Radius: 300

• Tire Stiffness: 200

• Wheel Mass: 10.0

• Sprung Mass: 1400

• CG Height: 300

• Wheelbase: 2765

• Drive Ratio: 100

All driving force is applied to the front wheels.

• Brake Ratio: 64

The brake ratio value indicates the % of braking force that is applied to the front brakes.

3. Select OK.

Performing the Analysis

Now that you’ve defined the vehicle parameters, you can run the parallel wheel travel analysis. During the

analysis, the test rig applies forces or displacements, or both, to the assembly, as defined in a loadcase file. For

this analysis, Adams Car generates a temporary loadcase file based on the inputs you specify.

This parallel wheel travel analysis moves the wheel centers from -100 mm to +100 mm relative to their input

position, while holding the steering fixed. During the wheel motion, Adams Car calculates many suspension

characteristics, such as camber and toe angle, wheel rate, and roll center height.

To perform the analysis:

1. From the Simulate menu, point to Suspension Analysis, and then select Parallel Wheel Travel.

2. Set up the analysis as follows:

• Suspension Assembly: my_assembly

• Output Prefix: baseline

• Number of Steps: 15

• Mode of Simulation: interactive

• Bump Travel: 100

• Rebound Travel: -100

• Travel Relative To: Wheel Center

• Steering Input: Angle

3. Select the Comment tool .

4. In the Comment Text text box, enter Baseline Parallel Wheel Travel Analysis.

5. Select OK.

37

Suspension Analysis Tutorial

Performing a Baseline Parallel Wheel Travel Analysis

6. Select OK again.

The Message Window appears, informing you of the steps Adams Car takes when performing the

analysis. Adams Car analyzes the suspension and steering assembly and applies to it the displacements

and loads defined in the submission dialog box.

7. When the analysis is complete, select Close.

Animating the Results

In this section, you view the analysis you just ran. Adams Car has already loaded the animation and graphic

files for you.

To animate the results:

1. From the Review menu, select Animation Controls.

2. Select the Play tool .

Adams Car animates the motion of the suspension analysis. Notice that the suspension moves from

rebound (down), to bump (up), and that the steering wheel does not rotate.

3. When the animation is complete, close the dialog box.

Plotting the Results

In this section, you create several plots from the parallel wheel travel analysis results. In a plot configuration

file, we have provided all the information that Adams Car needs to create the plots. The plot configuration

file not only specifies which plots Adams Car should create, but also how the plots should look, including

their horizontal and vertical units, and colors. Storing plotting information in a plot configuration file lets

you quickly regenerate plots after each analysis.

To plot the results:

1. Press F8 Key or Launch Adams PostProcessor as explained in Plotting Results.

2. From the Plot menu, select Create Plots.

3. Enter the following specifications:

• Plot Configuration File:

mdids://shared_car_database/plot_configs.tbl/mdi_suspension_short.plt

• Plot Title: Baseline Parallel Travel Analysis - UAN_FRT_SUSP

4. Select OK.

Adams Car creates the plots. To cycle through the plots, from the Main toolbar, use the Previous

Pages and Next Pages tools .

5. View the plot named

Scrub Radius, shown next. Scrub radius is the distance from the point at the

intersection of the steering axis (also known as the kingpin axis) and the ground plane, to the line of

intersection of the wheel and ground planes.

Getting Started Using Adams Car

Performing a Baseline Parallel Wheel Travel Analysis

38

Plot of Scrub Radius versus Wheel Travel

Notice that the scrub radius varies little with wheel travel and is approximately 34 mm. A positive

scrub radius means the steering axis lies inboard of the center of the tire contact patch.

From the analysis you’ve completed, you have enough information to calculate the approximate

torques produced about the steering axes using the difference in left to right braking forces and the

34 mm scrub radius.

In addition, using the results of that calculation and the steering geometry, you can calculate the

resulting unbalanced force at the steering rack and the pull (torque) needed at the steering wheel to

keep the wheels straight.

In the next sections, you use Adams Car to perform these calculations.

Deleting Plots

To prepare for the baseline pull analysis, delete the plots you created in the previous sections.

39

Suspension Analysis Tutorial

Performing a Baseline Pull Analysis

To delete plots:

1. In the treeview, hold down the left mouse button, and then drag the cursor across the names of the

plots you want to delete.

2. From the Edit menu, select Delete.

3. From the File menu, select Close Plot Window or press F8.

Adams Car returns to the main window.

Performing a Baseline Pull Analysis

You can now perform a baseline pull analysis to study the pull on the steering wheel. You will use the results

of this pull analysis as the baseline against which you compare the results of another pull analysis that you

perform after you modify the location of the steering axis. By comparing the results from the two analyses,

you can determine if the modifications were successful.

Performing a baseline pull analysis involves the following:

Defining a Loadcase File

Performing the Analysis

Animating the Results

Plotting the Results

Saving the Plot Configuration

Defining a Loadcase File

Before you can run the baseline pull analysis, you need to create a loadcase file to drive the analysis. In the

loadcase file, you specify the unequal braking forces to simulate braking on a split-μ surface and the

beginning, or upper, and ending, or lower, steering wheel angles.

To calculate the unequal brake forces, we assume that the vehicle is braking at a rate of 0.5 g’s deceleration,

with a 64% front and 36% rear brake ratio, a vehicle mass of 1,400 kg, and the front braking force split 55%

left and 45% right. Based on these assumptions, the total front braking force is:

1,400 kg * 0.5 g’s * 9. 81 m/s

2

/g * 0.64 = 4,395 N

From this, the left and right braking forces are:

Left braking force = 0.55 * 4,395 N or 2,417 N

Right braking force = 4,395 N - 2,417 N or 1,978 N

You can use these calculations to define the loadcase file.

Getting Started Using Adams Car

Performing a Baseline Pull Analysis

40

To define a loadcase file:

1. From the Simulate menu, point to Suspension Analysis, and then select Create Loadcase.

2. Fill in the dialog box as shown next, and then select OK.

Note: If Select Loadcase Type is not set to Static Load, your dialog box will look slightly

different. Make sure you select Static Load first, and then proceed to fill in the dialog

box.

41

Suspension Analysis Tutorial

Performing a Baseline Pull Analysis

Adams Car creates the loadcase file, named brake_pull.lcf, and stores it in your private database.

It stores the loadcase file as text (ASCII) and you can print it or edit it manually.

To create the loadcase file, Adams Car takes the parameters that you entered and generates a table of

input values. For the parameters that you entered, Adams Car generates a table that varies steering

wheel angle from -180 to 180 in 15 steps, while holding the braking forces constant.

Getting Started Using Adams Car

Performing a Baseline Pull Analysis

42

Table 1 shows the loadcase file values

:

Performing the Analysis

You can now use the loadcase file that you just created to perform an analysis that determines the pull

characteristics of the suspension and steering assembly.

To perform the pull analysis:

1. From the Simulate menu, point to Suspension Analysis, and then select External Files.

2. Set up the analysis as follows:

• Suspension Assembly: my_assembly

• Output Prefix: baseline

• Mode of Simulation: interactive

• Loadcase Files: mdids://private/loadcases.tbl/brake_pull.lcf

3. Make sure Load Analysis Results is selected.

4. Select OK.

Table 1 Loadcase file values

Steering Wheel: Left Brake Force: Right Brake Force:

-180 2417 1978

-156 2417 1978

-132 2417 1978

-108 2417 1978

-84 2417 1978

-60 2417 1978

-36 2417 1978

-12 2417 1978

12 2417 1978

36 2417 1978

60 2417 1978

84 2417 1978

108 2417 1978

132 2417 1978

156 2417 1978

180 2417 1978

43

Suspension Analysis Tutorial

Performing a Baseline Pull Analysis

Animating the Results

In this section, you view an animation of the analysis Adams Car just performed.

To animate the results:

1. From the Review menu, select Animation Controls.

2. Select the Play tool.

Adams Car animates the turning motion of the steering subsystem. You should see the wheels turn as

the steering wheel rotates. The wheel centers should not move vertically.

3. Close the Animation Controls dialog box.

Plotting the Results

You can now use the results from the baseline pull analysis to create two plots, as explained in the following

sections:

Plotting Steering Wheel Torque versus Steering Wheel Angle

Plotting Scrub Radius versus Steering Wheel Angle

Plotting Steering Wheel Torque versus Steering Wheel Angle

You now create a plot of the steering wheel torque versus the steering wheel angle.

To set up the plot:

1. Press F8 or Launch Adams PostProcessor just as you did before.

2. From the treeview, double-click page_1.

3. Select plot_1.

4. In the property editor, clear the selection of Auto Title and Auto Subtitle.

5. In the Title text box, enter Brake Pull Analysis.

6. In the Subtitle text box, enter Steering Wheel Torque vs Steering Wheel Angle.

7. Right-click the treeview area, point to Type Filter, point to Plotting, and then select Axes.

8. From the treeview, double-click plot_1, and then select haxis.

9. In the property editor, select the Labels tab.

10. In the Label text box, enter Steering Wheel Angle [degrees].

11. From the treeview, select vaxis.

12. In the Label text box, Steering Wheel Torque [Nmm].

To create the plot:

1. Verify that Source is set to Requests.

Adams Car automatically displays data information.

Getting Started Using Adams Car

Performing a Baseline Pull Analysis

44

2. From the Simulation list, select baseline_brake_pull.

3. From the right of the dashboard, set Independent Axis to Data.

The Independent Axis Browser appears. You perform the next four steps in the browser.

4. From the Filter list, select user defined.

5. From the Request list, select steering_displacements. You might have to scroll down to see this entry.

6. From the Component list, select angle_front.

7. Select OK.

8. From the Filter list, select user defined.

9. From the Request list, expand test rig in the Request list, and then select steering_wheel_input.

10. From the Component list, select steering_wheel_input_torque.

11. Select Add Curves.

Adams Car takes the data requested and automatically generates the curve on the current plot

template, as shown next:

Figure 3 Plot of Steering Wheel Torque versus Steering Wheel Angle

The plot shows the torque that the test rig applies to the steering wheel to hold the wheel in position.

The torque is negative, meaning that the test rig applies a clockwise torque to counteract the unequal

braking force that pulls the wheel counterclockwise, as if making a left turn.

45

Suspension Analysis Tutorial

Performing a Baseline Pull Analysis

Plotting Scrub Radius versus Steering Wheel Angle

In this section, you create a plot of the scrub radius versus the steering wheel angle. After you create the plot,

you can modify it to change the number of divisions in the vertical and horizontal axes so they cover a larger

range and define the minimum and maximum limits to be displayed in the vertical axis.

To set up the plot:

1. From the Main toolbar, select the New Page tool .

2. In the treeview, double-click page_2.

3. Select plot_2.

4. Make sure that Auto Title and Auto Subtitle are not selected.

5. In the Title text box, enter Brake Pull Analysis.

6. In the Subtitle text box, enter Scrub Radius vs Steering Angle.

7. Right-click the treeview area, point to Type Filter, point to Plotting, and then select Axes.

8. Double-click plot_2 to expand it so the names of the axes are visible.

9. From the treeview, select haxis.

10. In the property editor, select Labels.

11. In the Label text box, enter Steering Wheel Angle [degrees].

12. From the treeview, select vaxis.

13. In the Label text box, enter Scrub Radius [mm].

To create the plot:

1. Verify that Source is set to Requests.

2. From the Simulation list, select baseline_brake_pull.

3. From the Filter list, select user defined.

4. From the Request list, expand test rig in the Request list, and then select scrub_radius.

5. From the Component list, select left.

This defines the vertical axis component.

6. Select Add Curves.

Adams Car takes the data requested and generates the curve on the current plot template, as shown

next:

Getting Started Using Adams Car

Performing a Baseline Pull Analysis

46

Figure 4 Plot of Scrub Radius versus Steering Angle

Notice that the scrub radius appears to vary a lot with respect to the steering angle because of the

vertical plot scale, when in fact it only varies 0.21 mm over the total range of steering wheel angle. To

show that this variation is small, you must modify the vertical axis so it covers a larger range of values.

To modify the plot:

1. Select the vertical axis.

2. From the property editor, select the Format tab.

3. Clear the selection of Auto Scale.

4. In the Limits text boxes, enter 0 and 100.

A modified plot appears as shown next.

47

Suspension Analysis Tutorial

Modifying the Suspension and Steering Subsystem

Figure 5 Modified Plot of Scrub Radius versus Steering Wheel Angle

Notice that the variation in scrub radius with respect to the steering wheel angle now appears smaller.

Saving the Plot Configuration

Saving the changes that you made to the plots in a plot configuration file lets you easily recreate the plots later

in this tutorial, after you modify the suspension and steering assembly.

To save the plot configuration:

1. From the File menu, point to Export, and then select Plot Configuration File.

2. In the Configuration File Name text box, enter brake_pull.

3. Make sure All Plots is selected.

4. Select OK.

5. From the File menu, select Close Plot Window or press F8.

Adams Car returns to the main window.

Modifying the Suspension and Steering Subsystem

For a double-wishbone suspension, the line running from the lower spherical joint to the upper spherical joint

defines the steering axis or kingpin axis. If these joints move outboard while the rest of the suspension

geometry remains unchanged, the scrub radius is decreased.

In the suspension subsystem that you created, two hardpoint pairs define the locations of these joints:

Getting Started Using Adams Car

Modifying the Suspension and Steering Subsystem

48

hpl_lca_outer and hpr_lca_outer, where lca_outer means lower control arm outer, and

the prefix

hpl means hardpoint left and the prefix hpr means hardpoint right.

hpl_uca_outer and hpr_uca_outer, where uca_outer means upper control arm outer and the prefix

hpl means hardpoint left and the prefix hpr means hardpoint right.

Hardpoints define independent locations in space.

To decrease the scrub radius, you modify the locations that these hardpoints define, as explained in the

following sections:

Modifying Hardpoint Locations

Saving the Modified Subsystem

Modifying Hardpoint Locations

You must first display a table that contains data about the current locations that the hardpoints define. You

can then modify the hardpoint locations. You only need to indicate how you want to move the left hardpoints

in each pair, and Adams Car modifies the right hardpoints accordingly.

To view hardpoint locations:

1. From the View menu, select Subsystem.

The Display Subsystem dialog box appears, already containing the subsystem

my_assembly.UAN_FRT_SUSP.

2. Select OK.

3. From the Adjust menu, point to Hardpoint, and then select Table.

The Hardpoint Modification Table appears. It displays the locations of all the hardpoints in the

assembly. You can use this table to display and modify the locations of any of the hardpoints.

The locations of the paired hardpoints differ only by the sign of the Y location. Therefore, the paired

hardpoints are symmetrical about the X-Z plane. With symmetrical hardpoints, you only need to

move one of the hardpoints, not both. If you want, however, you can break the symmetry and move

only one of the hardpoints of a symmetrical pair.

To see the symmetry, select left or right from the bottom of the Hardpoint Modification Table.

To modify the hardpoints:

1. Click the cell common to hpl_lca_outer and loc_y.

2. Change the existing value to -775. This moves the hardpoint point 25 mm outboard.

3. Scroll the table window down until you see the hardpoint hpl_uca_outer.

4. Click the cell common to hpl_uca_outer and loc_y.

5. Change the existing value to -700. This moves the hardpoint 25 mm outboard.

6. Select Apply.

Adams Car changes the hardpoint locations of the two hardpoints and their symmetrical right pairs.

49

Suspension Analysis Tutorial

Performing an Analysis on the Modified Assembly

7. Close the dialog box.

Saving the Modified Subsystem

In this section, you save the subsystem you just modified.

To save the subsystem:

1. From the File menu, select Save.

Before saving the file, Adams Car asks you if you want to create a backup copy of the file.

2. Select No. This overwrites the subsystem file in your default writable database.

Adams Car saves the subsystem file that you created.

Performing an Analysis on the Modified Assembly

To determine how the modifications to the suspension subsystem changed the pull on the steering wheel, you

perform a pull analysis on the modified suspension and steering assembly. You can use the same loadcase file

that you created in Defining a Loadcase File.

To perform the analysis:

1. From the Simulate menu, point to Suspension Analysis, and then select External Files.

The dialog box displays the appropriate loadcase file.

2. In the Output Prefix text box, enter modified.

3. Select the Comment tool.

4. In the Comment Text text box, enter Steering axis moved 25mm outboard.

5. Select OK.

6. Select OK again.

Adams Car analyzes the modified suspension and steering assembly.

Comparing the Analysis Results

You now create a plot that compares the analysis results from the baseline suspension and steering assembly

with the analysis results from the modified suspension and steering assembly.

To compare the analysis results:

1. Press F8 to launch Adams PostProcessor.

2. From the Plot menu, select Create Plots.

3. In the Plot Configuration File text box, enter mdids://private/plot_configs.tbl/brake_pull.plt.

4. In the Plot Title text box, enter Brake Pull Analysis - UAN_FRT_SUSP.

Getting Started Using Adams Car

Comparing the Analysis Results

50

5. To plot the results of the two analyses on one page, select Cross Plotting.

6. Select OK.

7. Use the plot navigation tools to cycle through the plots.

8. Focus on the plot of the Steering Wheel Torque vs Steering Wheel Angle, shown in the following

figure. It contains values for both the baseline and the modified suspension and steering assembly.

Notice that the pull is reduced for all steering wheel angles, as expected.

Figure 6 Comparison Plot for Steering Wheel Torque vs Steering Wheel Angle

9. Cycle through the plots until you see a plot of the Scrub Radius vs Steering Wheel Angle, shown

below. This plot also contains values for both the baseline and the modified suspension and steering

assembly. Notice that the scrub radius decreased from 34 mm to about 9 mm because of the

suspension modifications.

51

Suspension Analysis Tutorial

Finishing Up

Figure 7 Comparison Plot for Scrub Radius versus Steering Wheel Angle

Finishing Up

Before you continue with the full-vehicle tutorial in the next chapter, you should clean up your directory by

deleting the plots and simulations, and closing the subsystems that you created and modified.

Deleting Simulations

Closing Assemblies

Deleting Simulations

You first delete the simulations for the baseline and modified analyses and then you return to the Adams Car

main window.

To delete simulations:

1. Right-click the treeview, point to Type Filter, point to Modeling, and then select Analyses.

2. To show the current simulations, double-click my_assembly.

The treeview updates and displays the current simulations.

3. Select the simulations you want to delete.

4. From the Edit menu, select Delete.

Adams Car deletes the simulations.

5. From the File menu, select Close Plot Window.

Adams Car returns to the main window.

Getting Started Using Adams Car

Finishing Up

52

Closing Assemblies

You can now close the suspension and steering assembly.

To close the assembly:

1. From the File menu, point to Close, and then select Assembly.

The Close Assembly dialog box appears. By default it contains the name of your assembly.

2. Select OK.

55

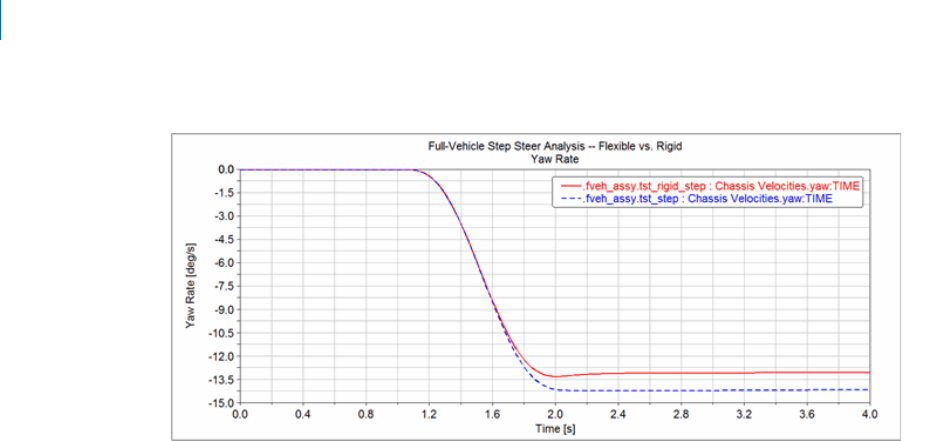

Flexible Bodies Tutorial

Overview

Flexible Bodies Tutorial

Overview

In this tutorial, you run analyses on suspension and full-vehicle assemblies to see the effects of flexible bodies.

Before you work through this tutorial, make sure you have:

Adams Flex.

Completed the tutorial we’ve provided with Adams Flex in the guide, Getting Started Using Adams

Flex.

A moderate level of finite element modeling proficiency.

This chapter includes the following sections:

About Modal Flexibility in Adams Car

What You Will Create and Analyze

Working with Flexible Bodies in Suspension Assemblies

Working with Flexible Bodies in Full-Vehicle Assemblies

This tutorial takes about one hour to complete.

About Modal Flexibility in Adams Car

Adams Car integrates and fully supports the Adams Flex plug-in. Adams Flex allows you to build flexible

bodies into your templates using a modes method, called modal flexibility. It assigns a set of mode shapes (or

eigenvectors) to a flexible body. The flexible body modeling element designates a system state variable to each

eigenvector and calculates the relative amplitude during a time analysis. The principle of linear superposition

is then used to combine the mode shapes at each time step to reproduce the total deformation of the flexible

body.

The following sections further explain flexible bodies:

About Integrating Flexible Bodies

About Flexible Body Damping Ratio

About Integrating Flexible Bodies

Integrating flexible bodies into templates or subsystems lets you capture inertial and compliance effects

during handling and comfort simulations, study deformations of your flexible components, and predict loads

with greater accuracy, therefore achieving more realistic results. Once the flexible body is created, Adams Car

displays its geometric representation in the main window.

The flexible body characteristics are defined in a finite element modeling (FEM) output file, called modal

neutral file or MNF. The information in an MNF includes:

Getting Started Using Adams Car

About Modal Flexibility in Adams Car

56

Geometry (location of nodes and node connectivity)

Nodal mass and inertia

Mode shapes

Generalized mass and stiffness for modal shapes

Alternatively, instead of specifying the MNF, the flexible body can also be created using MD DB, available

in MD solution. Using this, the user can instruct MD Nastran to create an MD DB that can be used by MD

Adams to create flexible bodies. The following are the highlights of this feature:

1. Multiple flexible bodies can be stored in one single database.

2. One database file is needed: .MASTER.

3. When multiple bodies presented in the database, user needs an additional parameter, INDEX, to

create a flexible body. User can browse the contents of a database and get the index of a body through

Adams Flex Toolkit.

4. It takes advantage of sophisticated Nastran Database access technology.

5. The database is platform-dependent.

When you integrate a flexible body into a template, you have to supply the following:

A modal neutral file. This means that the MNF should have been previously created and stored in a

shared or private database or the MD DB should present.

Location and orientation information for the part that you will create. Adams Car uses the location

and orientation information to rigidly rotate and translate the flexible body.

Inertia coupling and the damping ratio.

You can now integrate flexible bodies into your subsystems or assemblies. The process of swapping rigid bodies

with flexible bodies is fast, easy, and convenient, it eliminates the need for multiple templates, and is fairly

automatic. With rigid-to-flexible swapping, modal flexibility becomes a property of the body. When you

integrate a flexible body into a subsystem, you must:

Supply a modal neutral file. This means that the MNF should have been previously created and

stored in a shared or private database or the MD DB should present.

Position the flexible body with respect to the rigid parts. For help, from the Adjust menu, point to

General Part, select Rigid to Flex, and then press F1.

Monitor the connectivity. For help, from the Adjust menu, point to General Part, select Rigid to

Flex, and then press F1.

To successfully integrate a flexible body into an Adams Car template or subsystem and run simulations,

consider these precautions:

Use flexible bodies if a component flexibility affects the dynamic behavior of your model or if you

are interested in accurate deformations of the flexible body under various load conditions.

Because flexible body deformations are a linear combination of deformation shapes, be careful when

modeling components undergoing high nonlinear deformations.

Consider the computational load that a flexible body representation demands, especially if the MNF

description is very detailed, that is, if several modes have been included.

57

Flexible Bodies Tutorial

What You Will Create and Analyze

Verify your flexible body and check the natural frequencies associated with the significant mode

shapes and the mass and inertia properties.

About Flexible Body Damping Ratio

Dynamic system simulations are greatly complicated when the time integration must traverse a signal with

very high frequency components. To achieve the desired accuracy, Adams Solver must integrate the signal

with a possibly prohibitively short time step. Flexible bodies can contribute large amounts of high frequency

content and can, therefore, be difficult to simulate.

Carefully applying modal damping can help you successfully simulate a model containing flexible bodies.You

can specify a single scalar damping value applied to all the modes, control the damping using a

DMPSUB user-

written subroutine, or accept the default nonzero damping that Adams Flex applies to all the modes.

If you do not specify the damping, Adams Flex applies the following defaults:

1% damping for all modes with frequency lower than 100 Hz.

10% damping for modes with frequency between 100 and 1000 Hz.

100% critical damping for modes with a frequency higher than 1000 Hz.

During simulations, Adams Car displays in the Message Window the type of damping that you selected for

each flexible body in the model.

We suggest that in this tutorial you work with the default damping ratio.

What You Will Create and Analyze

This tutorial guides you through the following steps:

Creating, investigating, and successfully using flexible bodies in Adams Car templates.

Importing MNFs into existing subsystems to create models with flexible bodies.

Modifying flexible body properties by changing the modal contents, the inertia coupling, and the

damping ratio.

Modifying and analyzing a complete double-wishbone front suspension with flexible bodies.

Creating a full-vehicle assembly, analyzing it, and viewing the results.

Working with Flexible Bodies in Suspension Assemblies

In this section, you create a suspension assembly containing flexible lower control arms, learn how to manage

the flexible bodies in the assembly, and run an analysis and view its results. You compare the difference in

longitudinal wheel displacement by changing the left lower control arm to behave as a rigid body. A flexible

body behaves as a rigid body when you set the inertial invariants to rigid.

The following sections teach you how to work with flexible bodies in a suspension assembly:

Creating a Suspension Assembly

Managing Flexible Bodies

Performing a Suspension Analysis

Getting Started Using Adams Car

Working with Flexible Bodies in Suspension Assemblies

58

Animating Analysis Results

Plotting Analysis Results

Closing Suspension Assemblies

Creating a Suspension Assembly

You start out by creating a double-wishbone front suspension assembly. This assembly is based on the

_double_wishbone template. After opening a suspension assembly, you introduce flexible bodies by

performing a rigid-to-flex swap operation.

To create a suspension assembly:

1. Start Adams Car Standard Interface as described in Starting Adams Car Standard Interface.

2. From the File menu, point to New, and then select Suspension Assembly.

3. In the Assembly Name text box, enter susp_assy.

4. Right-click the Suspension Subsystem text box, point to Search, and then click on acar_shared and

select subsystems.tbl.

5. Double-click TR_Front_Suspension.sub.

Notice that by default Adams Car includes a suspension test rig in the assembly.

6. Select OK.

Adams Car displays the assembly (note that we turned the shading on):

Tip: For information on any dialog box, press F1 when the dialog box is active.

59

Flexible Bodies Tutorial

Working with Flexible Bodies in Suspension Assemblies

Figure 1 Double-Wishbone Suspension Assembly

Introducing Flexible Bodies

You use the rigid-to-flexible swap functionality to introduce flexible lower control arms to your suspension

assembly. Note that you are working on the subsystem (in previous versions, creating flexible bodies meant

that you had to create a new template, causing unnecessary template duplication).

To swap the rigid LCA with a flexible body:

1. Right-click ger_lower_control_arm, point to its name, and then select Modify.

2. Select Rigid to Flex.

3. Right-click the text box to the right of MNF File, and search the shared database for

LCA_right_tet.mnf.

Getting Started Using Adams Car

Working with Flexible Bodies in Suspension Assemblies

60

Adams Car creates a flexible body.

You don’t need to modify the location and orientation of the flexible body, because the MNF was

generated using a coordinate system coincident with the rigid part reference frame.

4. Select the Connections tab.

Adams Car fills in the table with all the markers belonging to the rigid part. All the markers will be

reassigned (by default) to the closest available node. You can select individual markers by highlighting

the row and changing the connection properties.

5. Select the Move column, and then select Preserve expression.

All markers will now maintain their location and orientation parametric expressions.

6. Select OK.

Adams Car deactivates the rigid body and replaces it with the corresponding flexible body.

7. Repeat the steps in this procedure for the left part, gel_lower_control_arm, making sure that you

select the MNF file named LCA_left_tet.mnf.

Managing Flexible Bodies

Managing flexible bodies involves verifying, modifying, and efficiently using flexible bodies. You can rigidly

rotate and translate flexible bodies, reposition them relative to the rest of the subsystem, as well as change

flexible body properties.

Displaying Information About Flexible Bodies

Displaying and Animating Modes

Changing Flexible Body Inertia Modeling

Displaying Information About Flexible Bodies

You can see if Adams Car correctly imported the flexible body into the template on which the suspension

subsystem is based, verify if the rigid-to-flex swap successfully placed the flexible body in the correct location,

and display information about the properties that define the flexible body.

To display information about a flexible body:

1. Right-click the left lower control arm flexible part, point to Flexible_Body:

TR_Front_Suspension.gel_lower_control_arm_flex, and then select Info.

The Information window appears as shown in the figure below. It lists the inertia properties, the

modal contents, and the name of the MNF that Adams Car used when creating the flexible body.

The Information window also shows how many modes are active for that flexible body.

61

Flexible Bodies Tutorial

Working with Flexible Bodies in Suspension Assemblies

Figure 2 Information Window

2. Select Close.

Displaying and Animating Modes

You can also verify flexible bodies by displaying and animating the modes, and viewing the corresponding

frequencies. The Mode Manager is a powerful tool that lets you define a scale factor to emphasize the

deformation of the flexible body, animate the flexible part, modify its modal content to improve the efficiency

of the simulation, and set initial conditions.

The MNF, as explained in the above sections, contains information about modes and frequencies that define

the flexible body.

To view and animate modes:

1. From the Adjust menu, point to General Part, and then select Modify.

Getting Started Using Adams Car

Working with Flexible Bodies in Suspension Assemblies

62

2. Right-click the General Part text box, point to Body, point to Pick, and from the screen, select the

left lower control arm, gel_lower_control_arm_flex.

3. Select the Mode Manager tool .

4. In the Mode Number text box, enter 8, and then press Enter.

In the Frequency text box, Adams Car displays the frequency corresponding to mode 8. In the main

window, note the bending of the flexible lower arm occurring at approximately 625 HZ.

5. Select Superimpose.

6. In the Frames text box, enter the number of animation frames.

7. Set Plot Type to Contour.

Adams Car highlights the flexible body deformation using color contours (note that we changed the

color of the underformed flexible body to red).

Figure 3 Flexible Dody Deformation Using Color Contours

8. Select the Animate tool .

Adams Car animates the bending mode that the flexible body undergoes at 345 HZ.

Leave the dialog box open, because you will use it again in the next section.

63

Flexible Bodies Tutorial

Working with Flexible Bodies in Suspension Assemblies

Changing Flexible Body Inertia Modeling

To be able to compare the suspension characteristics between the flexible right and the rigid left side, you

change the inertia modeling of the left lower control arm.

Adams Flex computes the time-varying mass matrix of the flexible body using nine inertia invariants. In

particular, four invariant formulations have special significance.

For more information about the invariant formulations, see the Adams Flex online help.

To change the inertia modeling:

1. Set Inertia modeling to Rigid body

2. Select OK.

3. Close the Modify Flexible Body dialog box.

Adams Car disables the 6th invariant, modal mass, and the flexible body becomes equivalent to a rigid

part. This causes all the modes to be ignored during the simulation.

Performing a Suspension Analysis

To simulate the flexible body subsystem, you run a suspension analysis and then you review the results,

focusing on the flexible body characteristics.

To perform a static load analysis on the suspension subsystem, you define upper and lower braking forces

applied at the hub.

To perform a static load analysis:

1. From the Simulate menu, point to Suspension Analysis, and then select Static Load.

2. Fill in the dialog box as shown next, and then select OK.

Getting Started Using Adams Car

Working with Flexible Bodies in Suspension Assemblies

64

Figure 4 Performing Static Load Analysis

65

Flexible Bodies Tutorial

Working with Flexible Bodies in Suspension Assemblies

Adams Car performs the analysis and displays messages about the simulation. The static load analysis

simulates the front suspension during a braking maneuver. The change in brake forces causes a

longitudinal wheel displacement.

Animating Analysis Results

You animate the results of the analysis to view the deformation of the left rigid arm compared to the right

flexible arm. During the animation, Adams Car applies a longitudinal force at the hub.

To animate the results:

1. From the Review menu, select Animation Controls.

2. Select the Play tool .

Adams Car animates the suspension.

Plotting Analysis Results

The flexibility of the right lower control arm affects a series of suspension characteristics that Adams Car

computes automatically. You can review the results of these calculations in the plotting environment.

Adams Car automatically loads the request file containing the suspension characteristics. Also, when a flexible